Environmental simulation device for high/low temperature fatigue property testing

A technology for fatigue performance testing and environmental simulation devices, which is applied to measuring devices, using stable tension/pressure to test material strength, strength characteristics, etc., to improve test efficiency, ensure application accuracy, and ensure accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

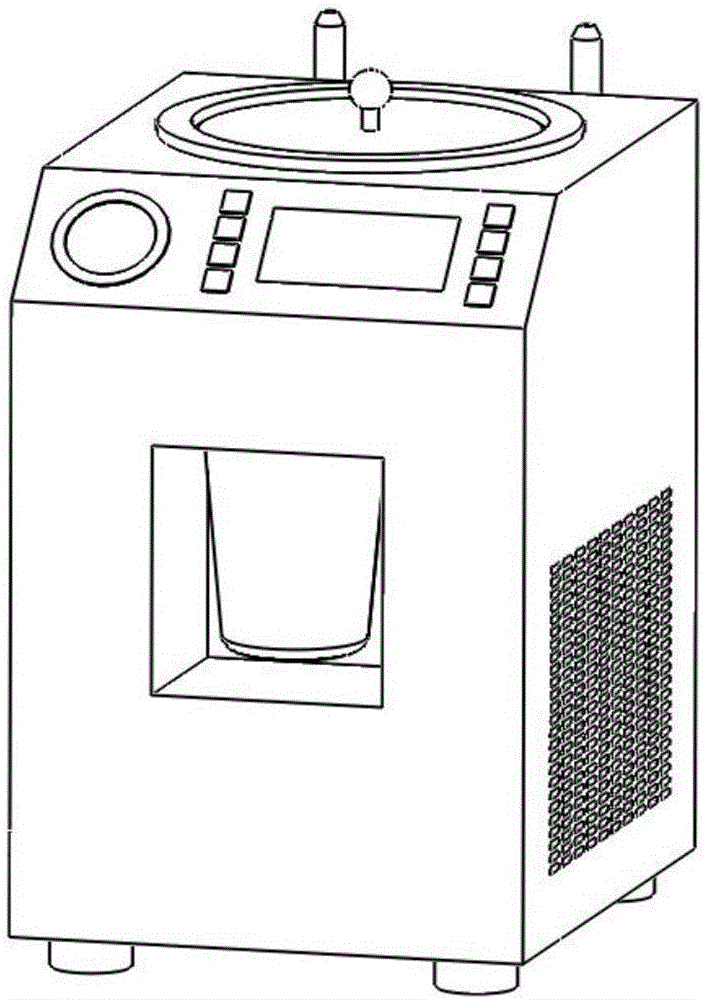

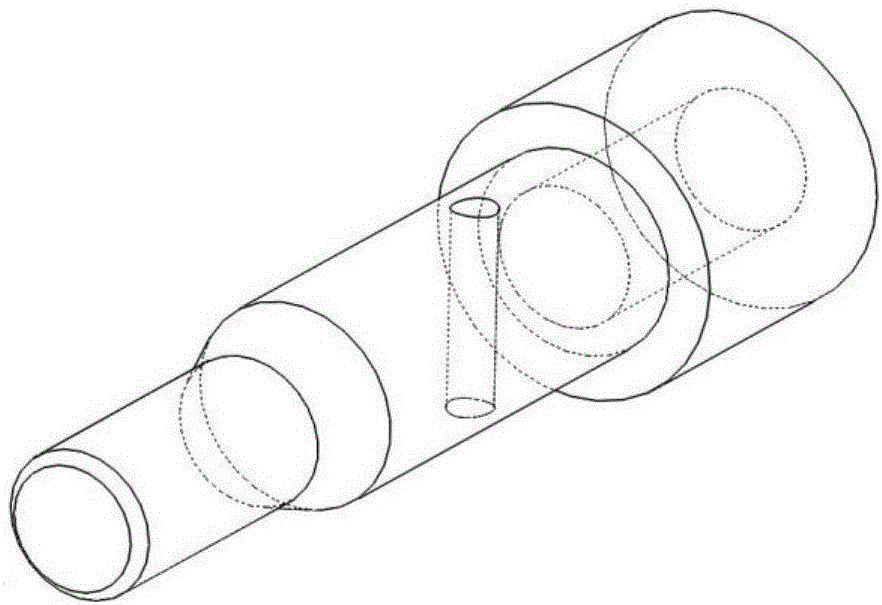

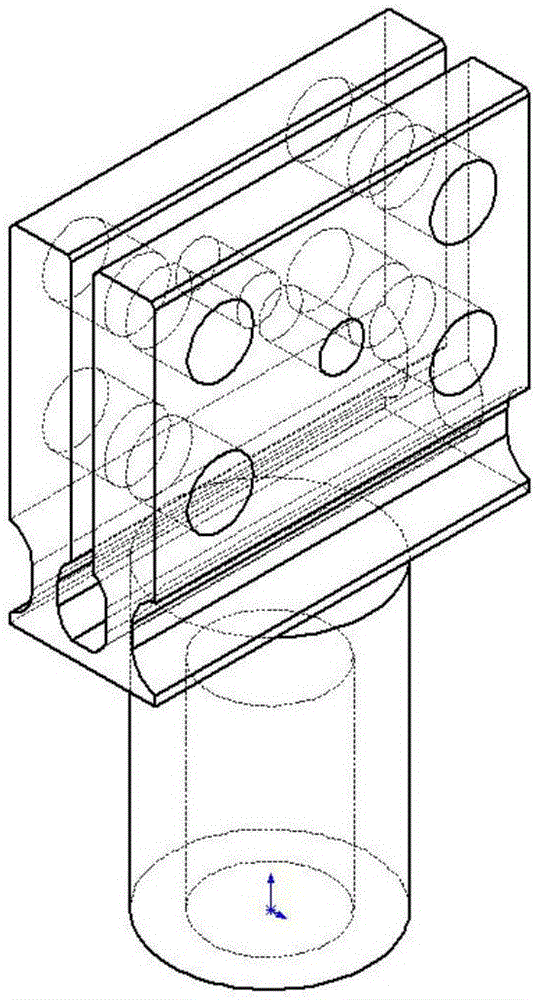

[0020] The invention is an environmental simulation device for high / low temperature fatigue performance testing, which consists of a high temperature-resistant multi-step circular shaft conversion joint, a temperature-controlled chiller, a high-temperature-resistant five-hole groove fixture, positioning pins and bolts, and an environmental chamber. And liquid nitrogen tank etc. composition. exist Figure 6 Among them, the high-temperature-resistant multi-step circular shaft conversion joint 2 is connected to the temperature-controlled chiller 1 through the inlet and outlet pipes to realize the cooling of the conversion joint in a high-temperature environment; one end of the high-temperature-resistant five-hole groove fixture 3 is installed on the high-temperature-resistant On the multi-step circular shaft conversion joint 2, the other end positions the sample through the positioning pin 4 and the positioning hole, and is fixedly connected with the sample 5 through the threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com