Real-time measurement apparatus of microgram magnitude quality and measurement method thereof

A real-time measurement and quality technology, applied in the field of measurement, can solve the problems of high-frequency and high-precision real-time measurement of microgram-level quality, and achieve the effect of high-precision and high-frequency measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

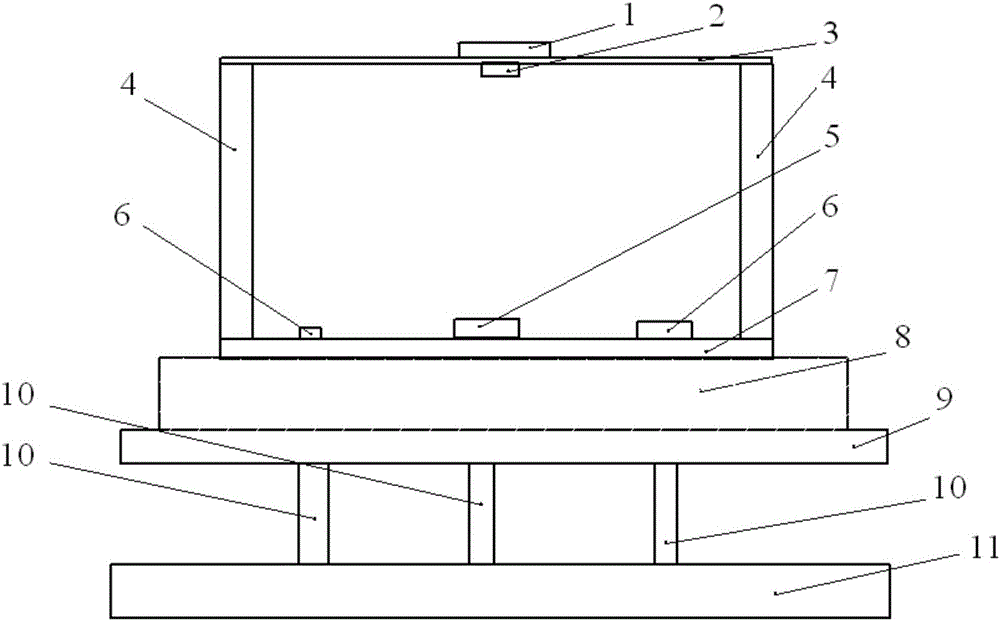

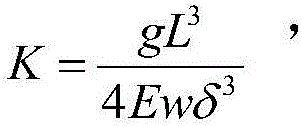

[0046] 1. Specific parameters:

[0047] In the present invention, the most important implementation parameters include: the size and material of the weighing elastic sheet 3, the non-contact displacement sensor 5, and the surface roughness of the detection target block 2, and the remaining parameters can be freely designed.

[0048] For example, the material of the weighing elastic piece 3 is nickel-chromium alloy steel, the elastic modulus E=206GPa, the size parameters L=10cm, w=1cm, δ=0.02mm.

[0049] The non-contact displacement sensor 5 is the LK-G85 laser displacement sensor of Keyence Corporation, the accuracy of the laser displacement sensor is 0.2 μm, and the measurement range is 1 mm.

[0050] The weighing tray 1 is an aluminum alloy cuboid, and its length, width and height are 50mm×50mm×2mm; the detection target block 2 is an aluminum alloy cuboid, its length, width and height are 5mm×5mm×2mm, and the surface roughness is 0.2μm .

[0051] Both the support platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com