Method for constructing fiber crack sensor on miter gate

A construction method and sensor technology, applied in the direction of converting sensor output, using optical devices to transmit sensing components, instruments, etc., can solve the problems of damage detection system, water pressure difference, dispersion, etc., and achieve optimization of wiring, efficient use of resources, The effect of taking up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

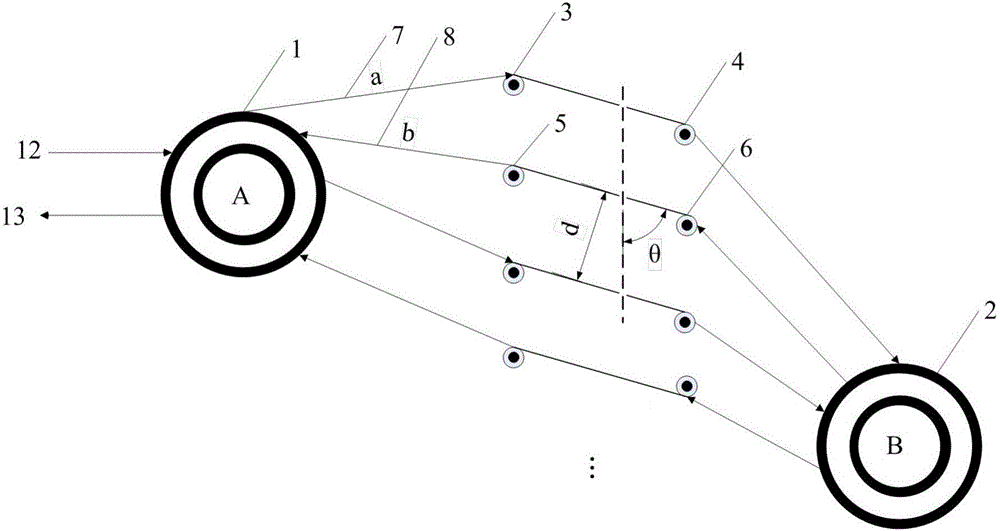

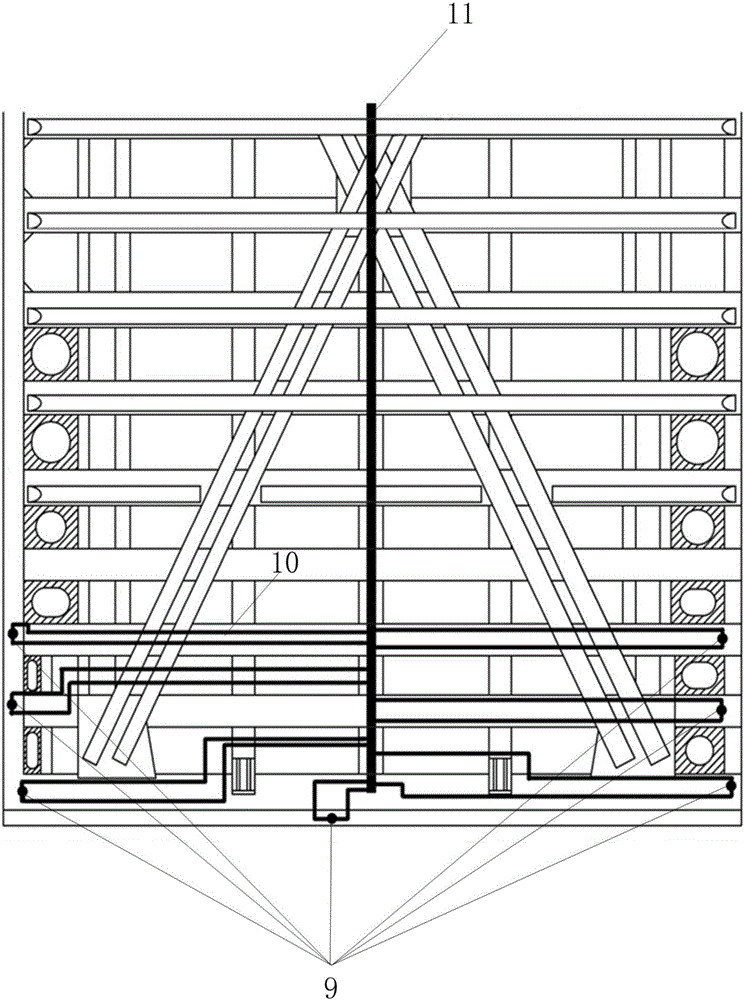

[0026] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings: It should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention. Such as Figure 1-2 Shown, a kind of construction method of miter gate optical fiber crack sensor is characterized in that: comprise the following steps:

[0027] A. Surface treatment of crack detection area

[0028] Determine the crack detection area, and polish the steel plate in the crack detection area, remove the attachments and anti-corrosion paint on the surface of the steel plate, expose the conductive layer, and make the surface smooth;

[0029] B. Determine the location of the fiber optic layout

[0030] Determine the interval d between adjacent optical fibers according to the accuracy requirements of the fixed length of the crack, and determine the angle θ be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com