Face structure light three-dimensional measuring system

A technology of three-dimensional measurement and surface structured light, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem of single test object in the measurement system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

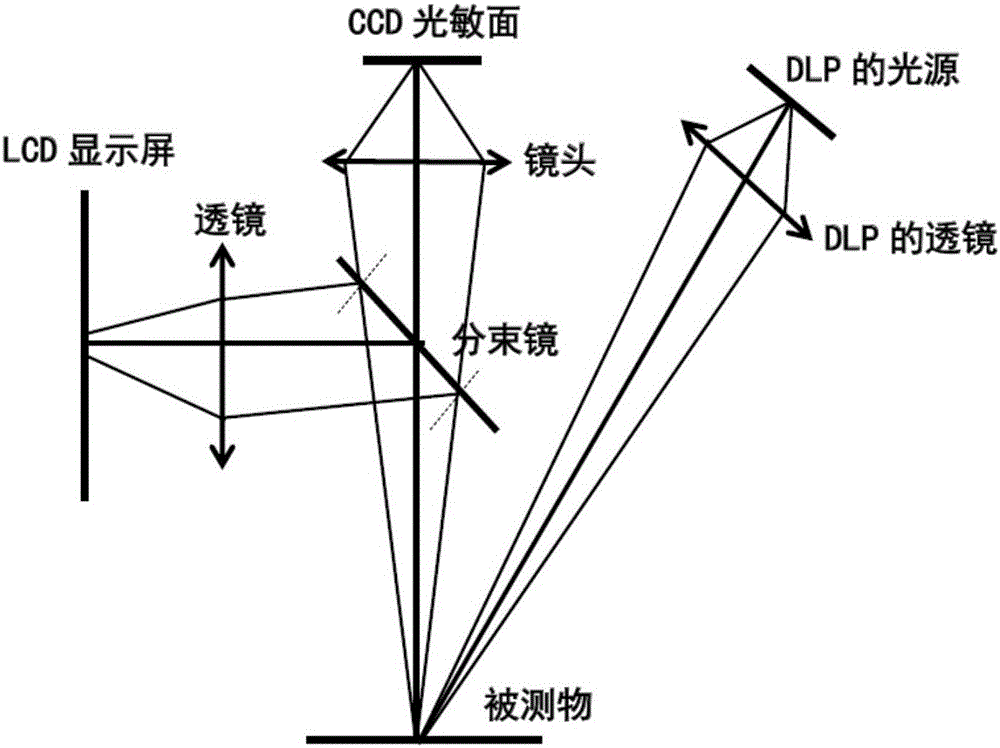

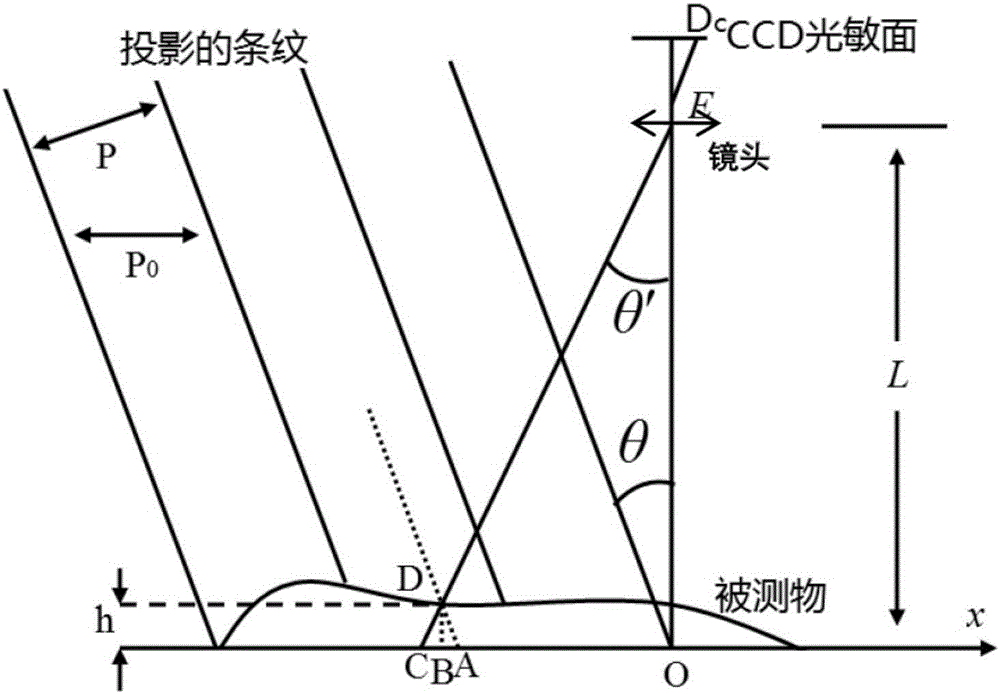

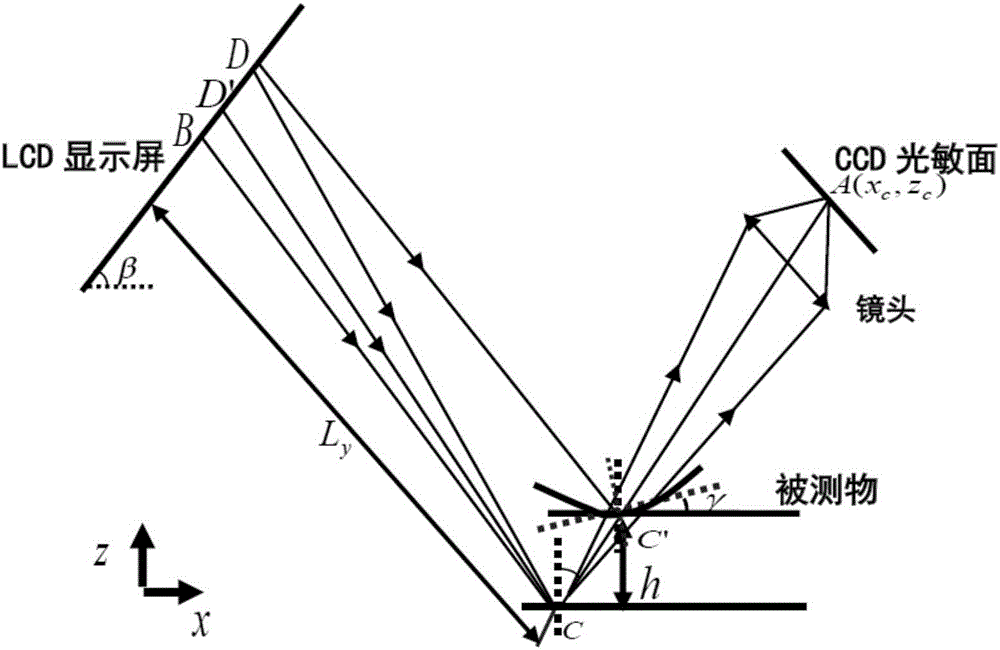

[0060] A surface structured light three-dimensional measurement system is characterized in that: the system includes a digital projection module (DLP) for structured light illumination, an LCD display, a CCD camera for receiving images, a lens, and a beam splitter for folding light paths; the system Based on the two lighting methods of striped projection structured light illumination and striped reflected structured light illumination, and organically combining the two, the high-precision measurement of the three-dimensional surface topography of objects with different roughness is realized. The height value of is used as the initial height value of the iteration, and the gradient value obtained when the stripe reflected structured light is illuminated is used as the iterative correction parameter for compound iteration; among them, for the diffuse reflection object, the iterative correction parameter in the algorithm is directly set to 0, while for the mirror surface Objects, ...

Embodiment 2

[0088] A surface-structured light three-dimensional measurement system, which realizes high-precision measurement of three-dimensional surface topography of objects with different roughnesses, overcomes the shortcomings of single measurement objects in traditional measurement systems, and has high sensitivity, high precision, non-contact, and compact structure. Smaller size and other advantages. Embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and the specific steps are as follows:

[0089] Step 1: If figure 1 Build a set of surface structured light three-dimensional measurement system designed by the present invention. In order to realize the measurement of the three-dimensional surface topography of objects with different roughness, the system organically integrates the stripe projection structured light illumination and the stripe reflection structured light illumination; the system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com