Temperature balanced electric heating furnace based on multi-area temperature control

A temperature control, electric heating furnace technology, applied in electric furnace heating, furnace heating elements, lighting and heating equipment, etc., can solve problems such as uneven temperature in the furnace cavity, and achieve the effect of eliminating overshoot and large fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

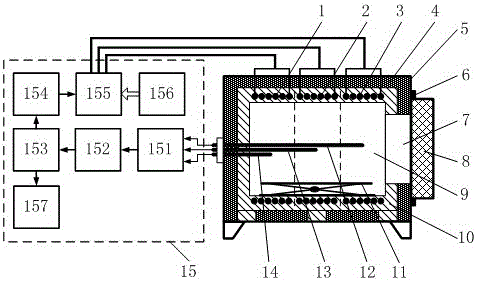

[0014] Specific implementation mode one: combine figure 1 Describe this embodiment mode, a temperature balanced electric heating furnace based on multi-zone temperature control described in this embodiment mode, it includes rear zone electric heating wire 1, middle zone electric heating wire 2, front zone electric heating wire 3, heat preservation Filler 4, furnace wall 5, rotating shaft 6, furnace mouth 7, furnace door 8, furnace cavity 9, furnace hearth 10, front zone thermocouple 12, middle zone thermocouple 13, rear zone thermocouple 14, temperature regulator 15.

specific Embodiment approach 2

[0015] Specific implementation mode two: combination figure 1 This embodiment is described. The difference between this embodiment and the first embodiment is that the furnace 10 is installed inside the furnace wall 5, and the furnace 10 and the furnace wall 5 are filled with the Insulation filling 4, the furnace mouth 7 is opened on the right side of the furnace 10 and the furnace wall 5, the furnace door 8 is installed on the right side of the furnace mouth 7, the The electric heating wire 1 in the rear area, the electric heating wire 2 in the middle area and the electric heating wire 3 in the front area are all installed in the reserved holes of the furnace 10, and are heated by heating up and down. The thermocouple in the front area The working end of 12 is positioned at the front zone center of described oven chamber 9, and the working end of described middle zone thermocouple 13 is positioned at the middle zone center of described furnace cavity 9, and the working end of...

specific Embodiment approach 3

[0016] Specific implementation mode three: combination figure 1 This embodiment is described. The difference between this embodiment and the specific embodiment 1 or 2 is that the furnace door 8 is fixed on the furnace wall 5 through the rotating shaft 6 and adopts a side door opening. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com