Refined control method of industrial combustion furnace

A refined control and combustion furnace technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of rough control and monitoring methods, poor degree of refinement, poor pertinence, etc., to monitor the flame state and reduce the flame height. , the effect of increasing operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The refined control method of the industrial combustion furnace of the present invention comprises the following steps:

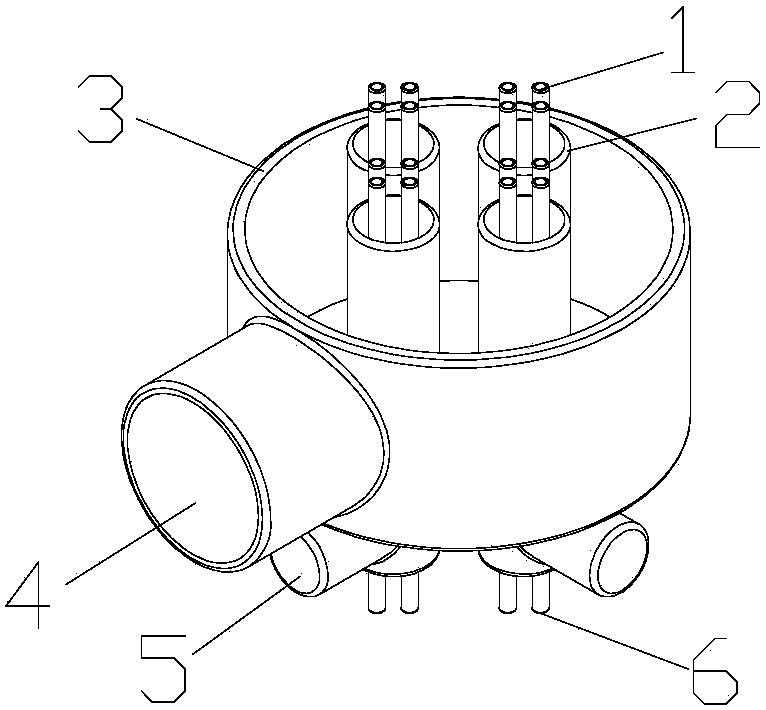

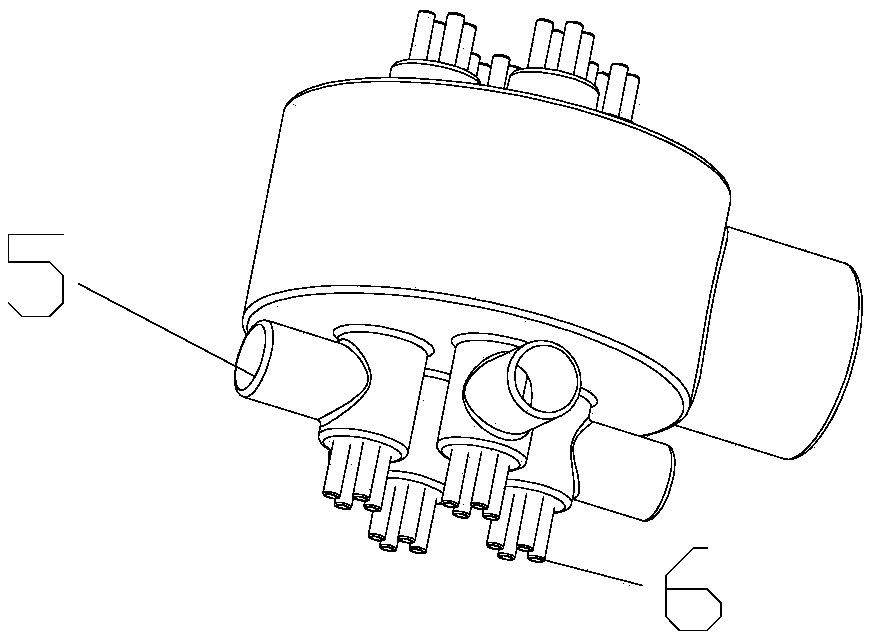

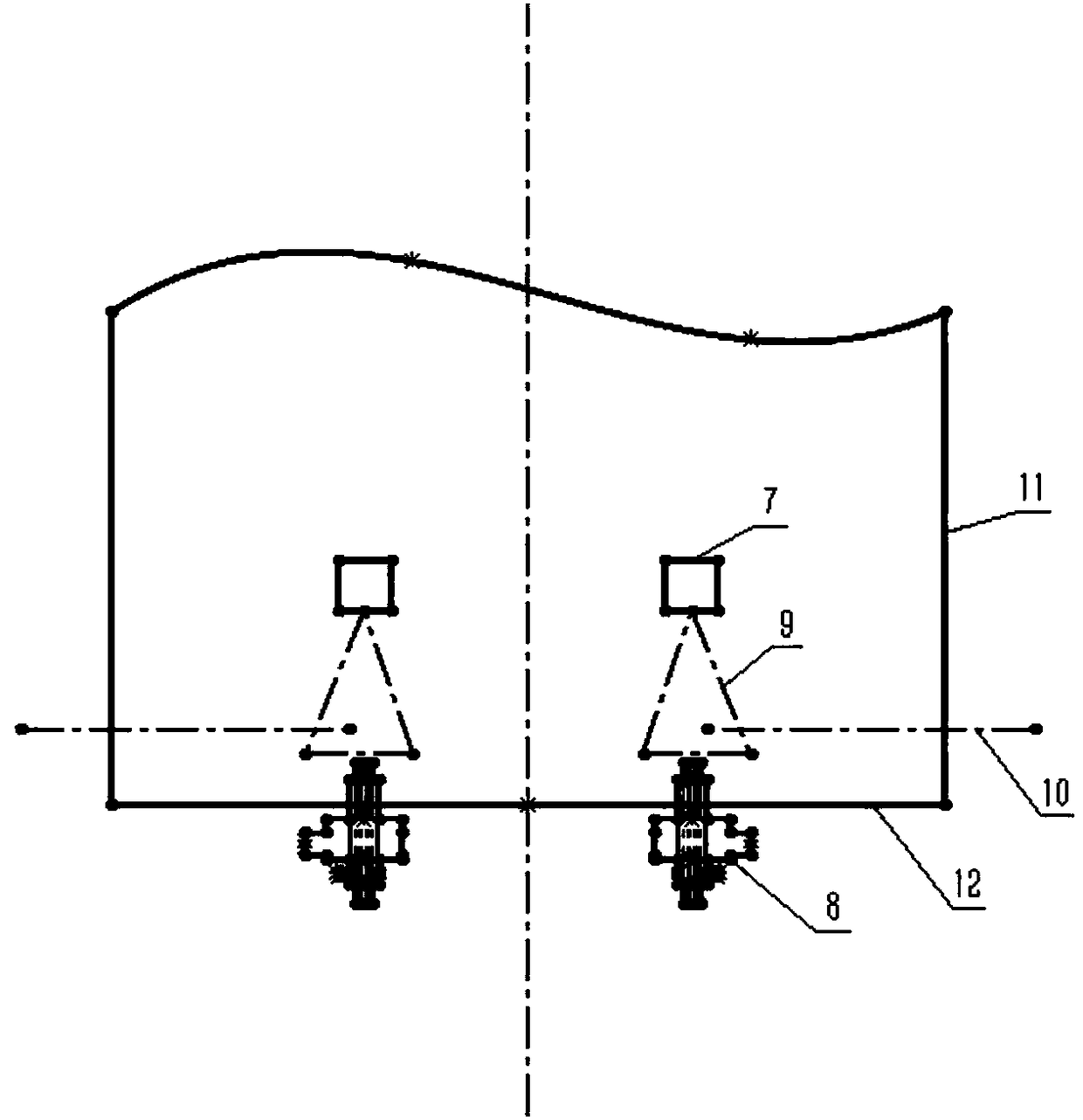

[0024] First, by figure 1 The medium fuel gas sleeve and the auxiliary gas sleeve are ignited to form a normal combustion flame, and then cooperate image 3 The monitor at the middle three-dimensional temperature field monitoring point observes the flame shape, gradually opens the assisted gas manifold to allow the assisted gas to pass through, and reduces the gas flow rate of the assisted gas sleeve. Based on the feedback data of the fuel concentration monitor, when the fuel is fully burned , try to shorten the flame trail and lower the flame height to a suitable position;

[0025] Secondly, when the flame combustion is stable, the fuel is fully combusted and the oxygen excess coefficient is as low as possible, according to the feedback data of the three-dimensional temperature field monitor, oxygen concentration monitor and fuel concentration moni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com