Novel composite drill rod

A drill rod and a new type of technology, applied in drill rods, drilling equipment, earth-moving drilling, etc., can solve the problems of improving the strength of the end of the drill rod, breaking the drill rod, affecting the construction efficiency, etc., and achieving good connection stability and cost. Control, service life improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

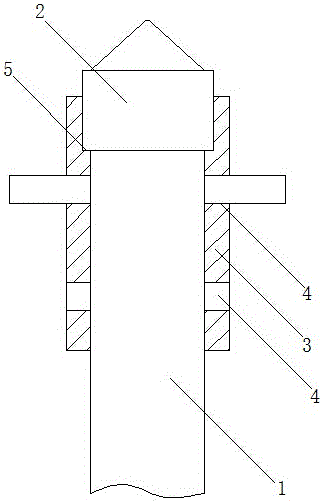

[0019] Such as figure 1 A new type of composite drill rod is shown, which includes a drill rod body 1, the end of the drill rod body 1 is provided with an alloy end portion 2, and the alloy end portion 2 adopts a tapered structure; the drill rod body 1 and the alloy end The parts 2 are connected by connecting sleeves 3, and at least one set of pin holes 4 are arranged on the connecting sleeves 3, and the drill rod body 1 and the connecting sleeves 3 are connected by pins.

[0020] As an improvement of the present invention, the novel composite drill rod is made by the following process steps:

[0021] 1) Take the seamless steel pipe according to the length requirement, and drill holes in the corresponding position of the seamless steel pipe to form pin holes, so that the seamless steel pipe forms a connecting sleeve;

[0022] 2) Insert a pin shaft into each pin hole in the connecting sleeve in step 1);

[0023] 3) Sintering the alloy end into shape, and placing the alloy end...

Embodiment 2

[0028] As an improvement of the present invention, two sets of pin holes 4 are arranged on the connecting sleeve 3 , which are uniformly distributed along the radial direction of the connecting sleeve 3 . By adopting the above-mentioned technical scheme, it can realize the connection of the drill rod body at different positions relative to the connecting sleeve through multiple sets of pin holes, so that it can be adjusted according to actual use requirements, so that the composite drill rod in this application Applicability is improved.

[0029] The remaining features and advantages of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0031] As an improvement of the present invention, at least one supporting end surface 5 is provided at the end of the connecting sleeve 3 opposite to the alloy end 2, which is arranged inside the connecting sleeve 3, and the supporting end surface 5 is perpendicular to the connection The radial direction of the sleeve 3 extends; the alloy end 2 extends to the inside of the connecting sleeve 3 and fits on the supporting end surface 5 . By adopting the above-mentioned technical solution, the setting of the supporting end surface enables the alloy end to be supported in multiple directions during forming and subsequent work, so that its working strength can be further improved.

[0032] The remaining features and advantages of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com