An integrated device for slope concrete protection

A concrete and integrated technology, applied in excavation, construction, infrastructure engineering, etc., can solve the problems of low construction efficiency of manual excavation trenches, difficulty in achieving on-site civilized construction, and difficulty in excavation construction, so as to ensure the quality of alignment and appearance Requirements, facilitate inspection and acceptance, and realize the effect of information management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

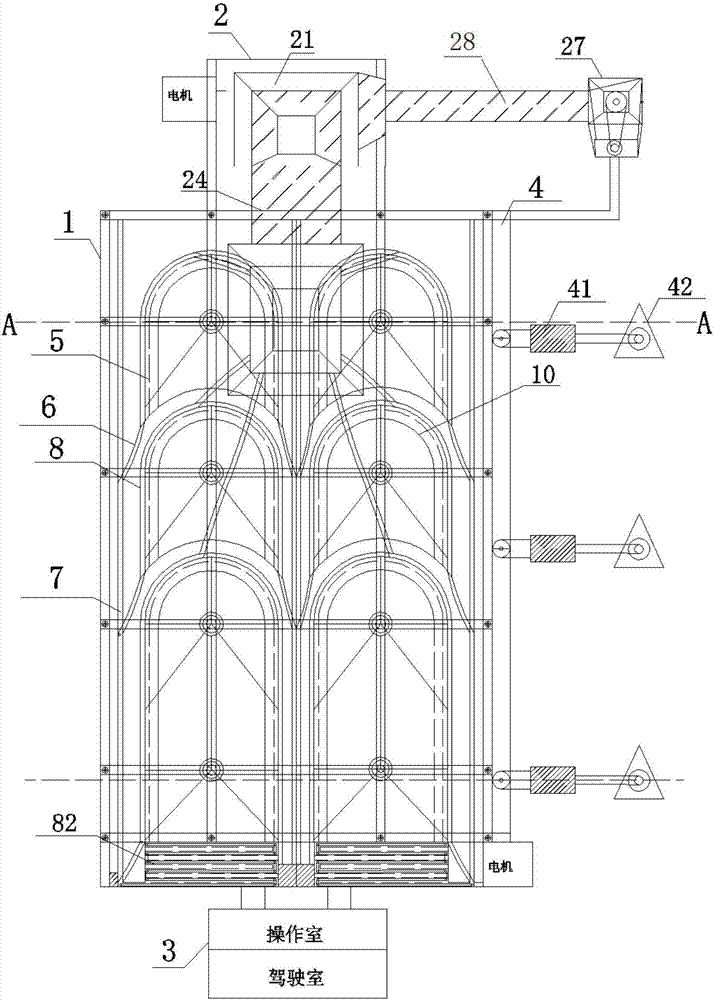

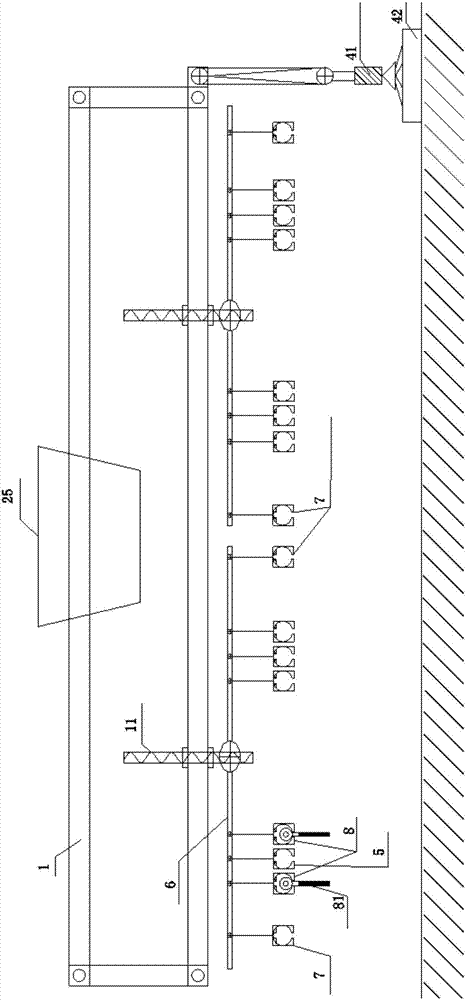

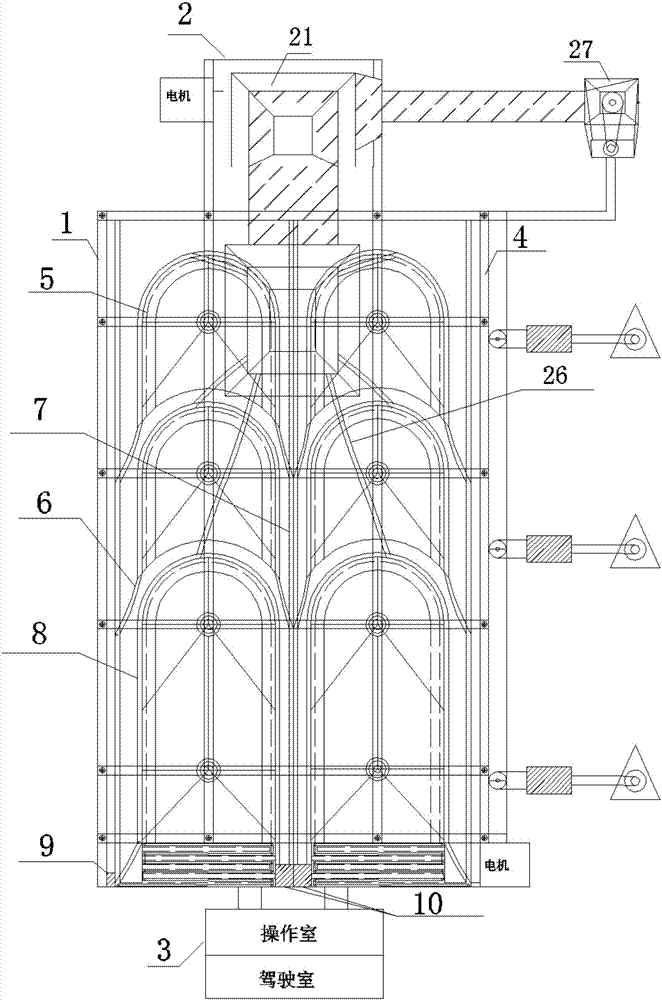

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1 As shown, an integrated equipment for slope concrete protection, the specific structure includes a slope top running device 2 and a slope bottom running device 3, and is connected across the slope surface between the slope top running device 2 and the slope bottom running device 3 The rectangular main frame 1; the main frame 1 is provided with a front running track 4 on one side of the forward direction, and the front running track 4 is provided with a leg 12, and the leg 12 is provided with an adjustable hydraulic cylinder 41, and the bottom of the leg 12 is An excavation pick 42 is provided; the main frame 1 is also provided with a linear transport track 7 parallel to the front side running track 4, and the linear transport track 7 is connected to the formwork storage area 82; a formwork track 8 is provided directly b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com