Bridge rotating construction rotating spherical hinge with self-centering function

A self-centering and spherical hinge technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of low bearing capacity of concrete hinges, uneven force, and few applications, so as to improve construction convenience and reliability performance, shorten the manufacturing period, and optimize the effect of the spherical joint structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

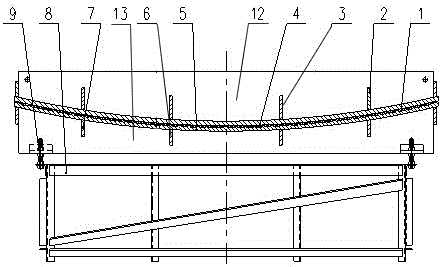

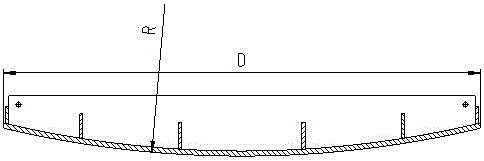

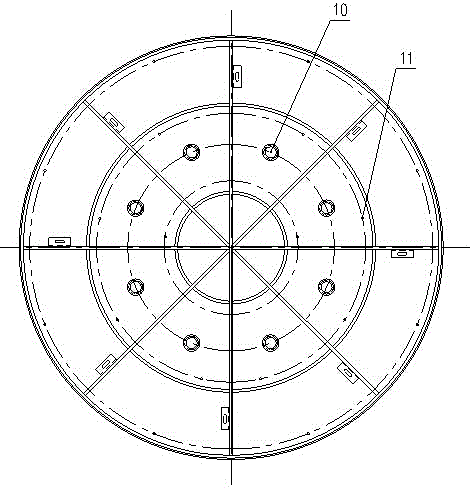

[0012] As shown in the figure, a swivel spherical joint for bridge swivel construction with self-centering function, including an upper spherical joint, a lower spherical joint, and a non-metallic slide plate with a multi-layer structure.

[0013] The upper spherical hinge includes an upper spherical hinge spherical panel and an upper spherical hinge rib plate, and the upper spherical hinge spherical panel is a convex spherical surface; the upper spherical hinge spherical panel is a complete structure without opening a hole in the center of the spherical hinge , the inner side of the upper ball hinge spherical panel has several radially arranged ribs and several annular (polygonal) ribs, and the radial ribs and annular (polygonal) ribs are welded to each other and welded to the upper ball hinge spherical panel above, forming a frame structure.

[0014] The lower ball hinge includes a lower ball hinge spherical panel and a lower spherical hinge rib plate, and the lower spherica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com