PVC decorative film and preparation method thereof

A decorative film and coating technology, applied in the field of PVC decorative film and its preparation, can solve the problems of rough hand feeling and low surface flatness, and achieve the effects of improving coating uniformity, surface compactness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

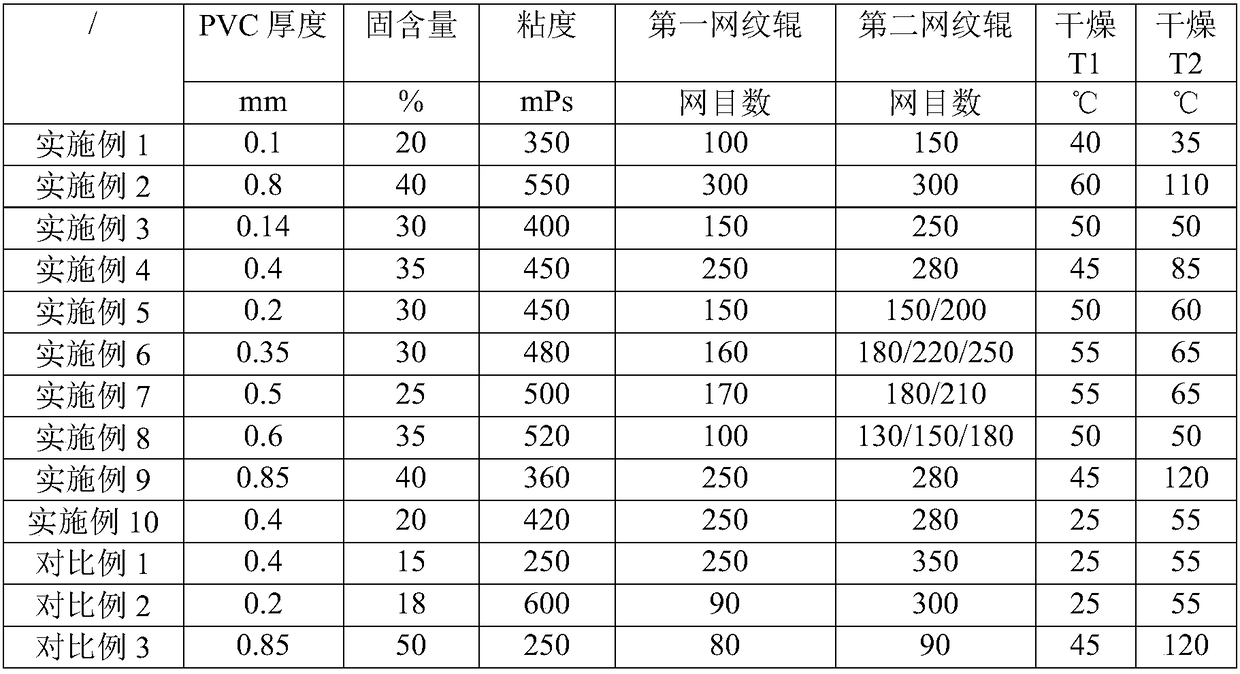

[0019] As mentioned in the background technology, the flatness of PVC film materials in the existing decoration material market is relatively low, and the hand feeling is not delicate enough to meet the defects of high-end decoration requirements. In a typical embodiment of the present invention, a A method for preparing a PVC decorative film, the preparation method comprising: step S1, using a first anilox roller of 100-300 mesh to roll-coat a bridging agent on a PVC fabric to obtain a primer film; step S2, using a first anilox roller of 100-300 mesh The second anilox roll coats the water-based PU slurry on the primer film to obtain a PVC decorative film.

[0020] In the above-mentioned preparation method of the present invention, the anilox roll of specific mesh is carried out the bridging agent roller coating, and the surface treatment mode that the anilox roller of specific mesh carries out the water-based PU paste roller coating of combination, not only helps to control ea...

Embodiment 1

[0039] Surface treatment is carried out on the PVC fabric containing the three-layer structure of the bottom layer, the surface layer and the back coating, and the thickness of the PVC fabric is 0.10mm.

[0040] First, a 100-mesh anilox roller is used to roll-coat the bridging agent on the PVC fabric, and after the roller coating, place it in hot air at 40°C for drying to obtain a primer film.

[0041] Then use a 150-mesh anilox roller to roll-coat water-based PU slurry on the bottom coating film, and the obtained water-based PU layer will be dried in hot air at 35°C after roller coating, and then the entire PU-PVC composite film after drying The embossed layer is processed to obtain a PVC decorative film.

Embodiment 2

[0043] Surface treatment is carried out on the PVC fabric containing the three-layer structure of the bottom layer, the surface layer and the back coating, and the thickness of the PVC fabric is 0.80mm.

[0044] First, a 300-mesh anilox roller is used to roll-coat the bridging agent on the PVC fabric, and after the roller coating, place it in hot air at 60°C for drying to obtain a primer film.

[0045] Then use a 300-mesh anilox roller to roll-coat the water-based PU slurry on the bottom coating film. After the roll coating, place it in hot air at 110°C for drying, and then emboss the entire PU-PVC composite film layer after drying. , to obtain a PVC decorative film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com