Looper threading device of circular sewing machine

A technology of a threading device and a looper, which is applied in the direction of sewing equipment, sewing machine components, sewing machine collar mechanisms, etc. It can solve the problems of large flow resistance and inability to guide the looping thread, etc., and achieve the effect of suppressing air blowout and good threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] [Overall structure of the embodiment]

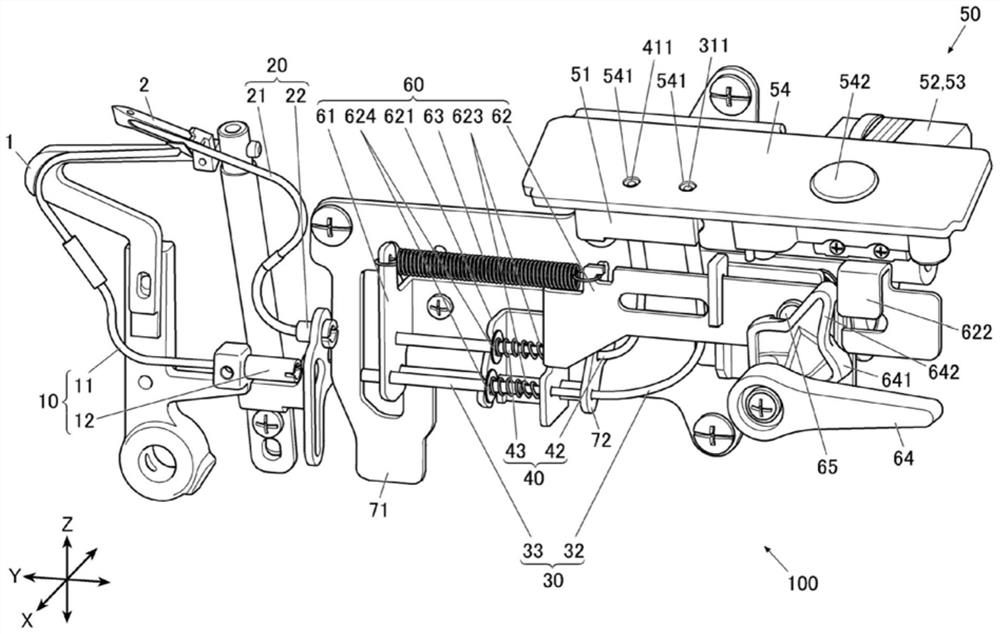

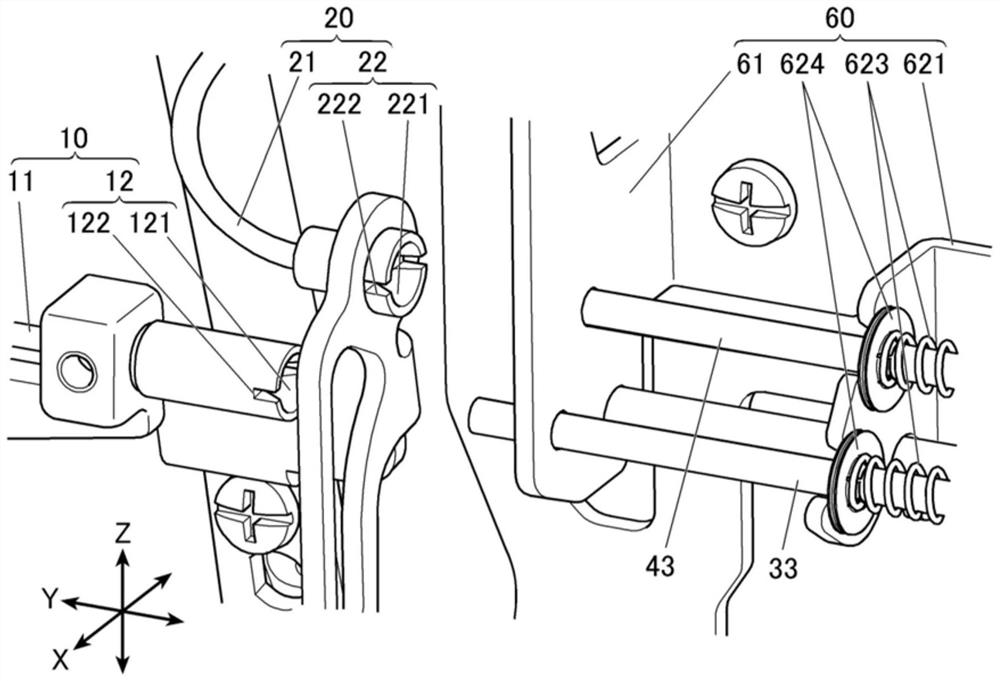

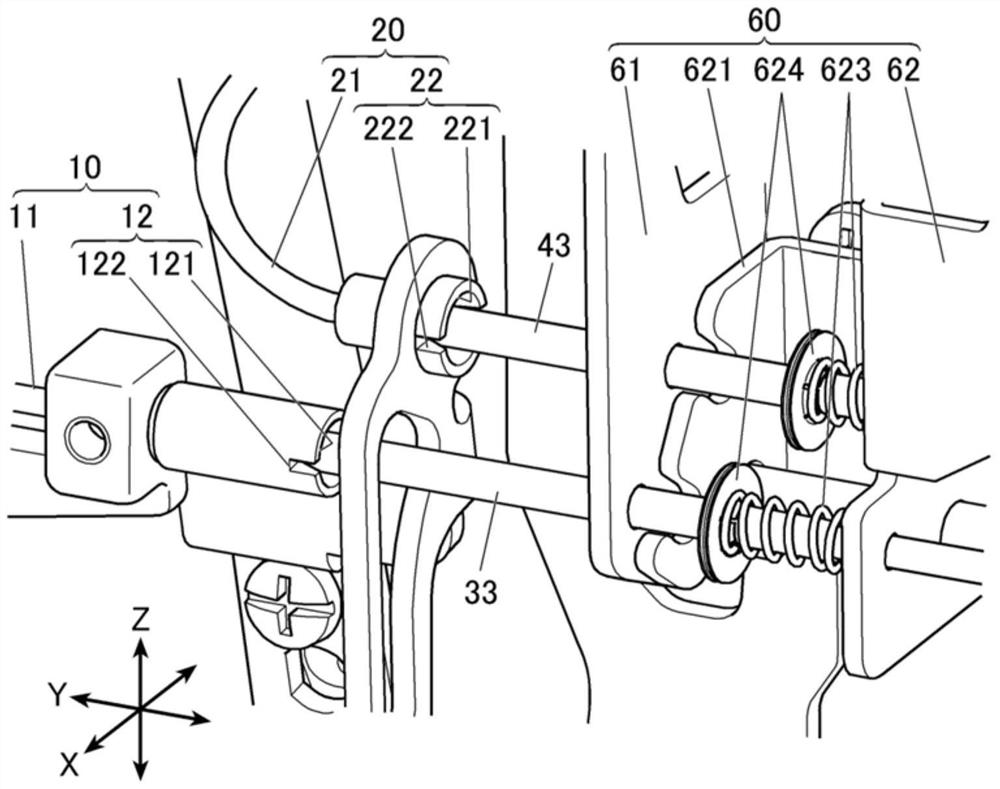

[0072] based on Figure 1 to Figure 12 , the looper threading device 100 mounted on the overlock sewing machine as the circular sewing machine according to the embodiment of the present invention will be described. figure 1 It is a perspective view of the looper threading device 100. In addition, in figure 1 Among them, the Z-axis direction represents the vertical up-down direction, the X-axis direction represents the direction in which the material is conveyed horizontally, and the Y-axis direction represents the horizontal direction perpendicular to the X-axis direction. In addition, the Y-axis direction and the longitudinal body side of the sewing machine may be referred to as the rear, and the face side may be referred to as the front.

[0073] The overlock sewing machine includes a lower looper 1 and an upper looper 2, which are provided on the lower side of a needle plate and reciprocate synchronously with the vertical mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com