Spherical solid foam scrubbing agent for natural gas fluctuation horizontal well

A foam discharge agent and a technology for horizontal wells, which are applied in the directions of production fluid, wellbore/well components, drilling composition, etc., can solve the problem of inability to use foam discharge agent, inability to apply undulating horizontal well sections, and no spherical solid foam discharge. problems such as agent ideas, products, process design methods and theoretical basis research to achieve the effect of improving drainage efficiency and easy management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

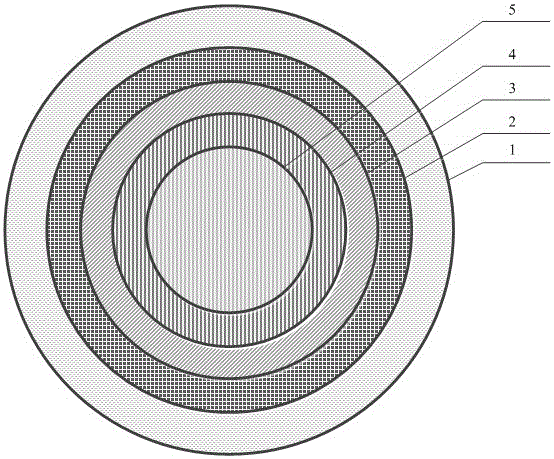

[0011] The structure and implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] Assume that the spherical solid foam release agent is composed of five layers of foam release agents, namely the first layer of foam release agent 1, the second layer of foam release agent 2, the third layer of foam release agent 3, the fourth layer of foam release agent 4, the fifth layer of foam release agent The laminar defrosting agent is composed of 5 and constitutes a concentric sphere. Each layer has a different density due to the difference in porosity and the presence or absence of weighting materials. Setting requirements: The formula used for the first, third and fifth layers of foam discharge agent is formula A, and the material and weight ratio of each component are: sodium dodecylsulfonate 35%, fatty alcohol polyoxyethylene ether 15%, acrylic resin 10% %, sodium bicarbonate 32%, urea 8%. Formula A foam discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com