Polyethylene master batch for packaging bags and preparation method thereof

A technology for polyethylene and packaging bags, which is applied in the field of polyethylene masterbatch for packaging bags and its preparation, can solve the problems of poor anti-oxidative and fresh-keeping performance and cannot be used, and achieves the advantages of extending service life, improving mechanical properties and reducing photoaging effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

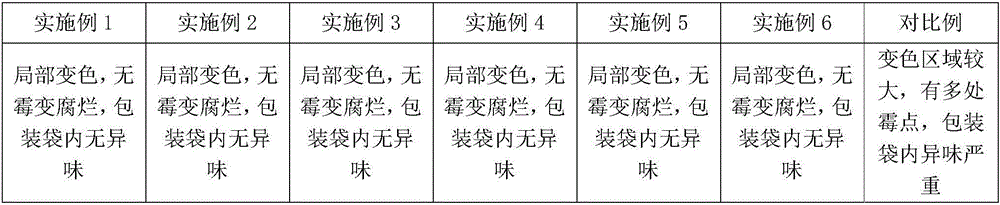

Examples

Embodiment 1

[0029] Prepare polyethylene masterbatch for packaging bags as follows:

[0030] (A) Wash the oats with distilled water, dry them in the shade, place them in a vacuum drying oven and dry them at 60°C for 5 hours, take them out, put them in a pulverizer, and then pass them through a 80-mesh sieve to obtain oat flour;

[0031] (B) Add the oat flour obtained in step (1) into the ethanol solution with a volume fraction of 66%, the solid-liquid ratio of oat flour and ethanol solution is 1:10g / mL, mix well and place in a microwave oven with a microwave power of 600W In the heater, extract by microwave radiation for 20 minutes, suction filter after the extraction is completed, place the obtained extract on a rotary evaporator to recover ethanol, and obtain a crude oat extract;

[0032] (C) The oat extract obtained in step (2) is eluted with distilled water to remove sugar, and then eluted with an ethanol solution with a volume fraction of 66%, and the eluent is evaporated under reduce...

Embodiment 2

[0037] Prepare polyethylene masterbatch for packaging bags as follows:

[0038] (A) Wash the oats with distilled water, dry them in the shade, place them in a vacuum drying oven and dry them at 60°C for 5 hours, take them out, put them in a pulverizer, and then pass them through a 80-mesh sieve to obtain oat flour;

[0039] (B) Add the oat flour obtained in step (1) into the ethanol solution with a volume fraction of 66%, the solid-liquid ratio of oat flour and ethanol solution is 1:10g / mL, mix well and place in a microwave oven with a microwave power of 600W In the heater, extract by microwave radiation for 20 minutes, suction filter after the extraction is completed, place the obtained extract on a rotary evaporator to recover ethanol, and obtain a crude oat extract;

[0040] (C) The oat extract obtained in step (2) is eluted with distilled water to remove sugar, and then eluted with an ethanol solution with a volume fraction of 66%, and the eluent is evaporated under reduced ...

Embodiment 3

[0045] Prepare polyethylene masterbatch for packaging bags as follows:

[0046] (A) Wash the oats with distilled water, dry them in the shade, place them in a vacuum drying oven and dry them at 60°C for 5 hours, take them out, put them in a pulverizer, and then pass them through a 80-mesh sieve to obtain oat flour;

[0047] (B) Add the oat flour obtained in step (1) into the ethanol solution with a volume fraction of 66%, the solid-liquid ratio of oat flour and ethanol solution is 1:10g / mL, mix well and place in a microwave oven with a microwave power of 600W In the heater, extract by microwave radiation for 20 minutes, suction filter after the extraction is completed, place the obtained extract on a rotary evaporator to recover ethanol, and obtain a crude oat extract;

[0048] (C) The oat extract obtained in step (2) is eluted with distilled water to remove sugar, and then eluted with an ethanol solution with a volume fraction of 66%, and the eluent is evaporated under reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com