Polyethylene water supply pipe with antibacterial performance and preparation method thereof

A technology for water supply pipes and polyethylene, which is applied in the field of polyethylene water supply pipes with antibacterial properties and its preparation, can solve the problems of reduced antibacterial ability, excessive production cost, limited application and the like, meets the requirements of water quality, and has a simple manufacturing process. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

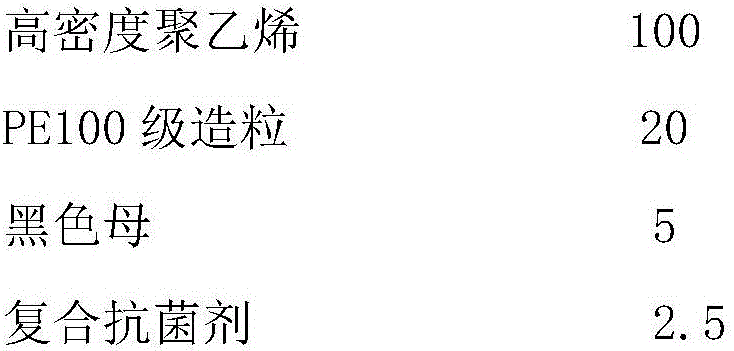

[0019] The formulation of the antibacterial polyethylene water supply pipe consists of the following raw materials in parts by mass:

[0020]

[0021] Put the above-mentioned raw materials in a mixer according to the weight portion and stir them evenly, introduce the blend into an extruder for granulation, and extrude the granulated granules through a single-screw extruder to obtain a polyethylene water supply pipe.

[0022] Mixing and stirring: Put the above raw materials into the mixer in turn, and the stirring time is 25min (20-30min);

[0023] Extrusion granulation: Put the uniformly mixed materials into the twin-screw extruder for blending and granulation. The temperature range of each section of the extruder is: 175°C-220°C;

[0024] Extrusion molding, extruding the granulated particles through a single-screw extruder to obtain a polyethylene water supply pipe, the temperature of the barrel is 180°C, and the temperature of the die is 220°C.

Embodiment 2

[0026] The formulation of the antibacterial polyethylene water supply pipe consists of the following raw materials in parts by mass:

[0027]

[0028] Put the above-mentioned raw materials in a mixer according to the weight portion and stir them evenly, introduce the blend into an extruder for granulation, and extrude the granulated granules through a single-screw extruder to obtain a polyethylene water supply pipe.

[0029] Mixing and stirring: put the above raw materials into the mixer in turn, and the mixing time is 30 minutes;

[0030] Extrusion granulation: Put the uniformly mixed materials into the twin-screw extruder for blending and granulation. The temperature range of each section of the extruder is: 175°C-220°C;

[0031] Extrusion molding: Extrude the granulated granules through a single-screw extruder to obtain a polyethylene water supply pipe. The temperature of the barrel is 200°C, and the temperature of the die is 225°C.

Embodiment 3

[0033] The formulation of the antibacterial polyethylene water supply pipe consists of the following raw materials in parts by mass:

[0034]

[0035] Put the above-mentioned raw materials in a mixer according to the weight portion and stir them evenly, introduce the blend into an extruder for granulation, and extrude the granulated granules through a single-screw extruder to obtain a polyethylene water supply pipe.

[0036] Mixing and stirring: put the above raw materials into the mixer in turn, and the stirring time is 20min (20-30min);

[0037] Extrusion granulation: Put the uniformly mixed materials into the twin-screw extruder for blending and granulation. The temperature range of each section of the extruder is: 175°C-220°C;

[0038] Extrusion molding: Extrude the granulated granules through a single-screw extruder to obtain a polyethylene water supply pipe. The temperature of the barrel is 220°C, and the temperature of the die is 230°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com