Self-degradable leaking-prevention and stoppage material and preparation method thereof, self-degradable leaking-prevention and stoppage product and application thereof

A plugging material and self-degradation technology, which is applied in the field of petroleum exploration, can solve the problems of incompatibility, easy leakage, and high density of inorganic salt solution due to the coexistence of various leakages, and achieve excellent self-degradation performance, synergistic optimization, Effect of Excellent Permeability Recovery Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

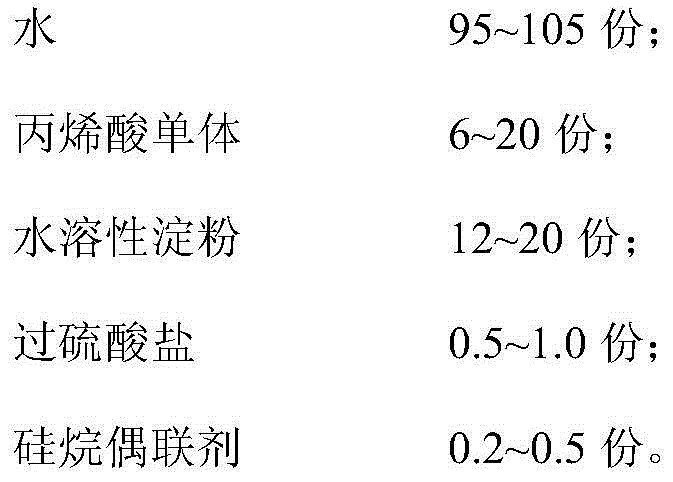

[0028] In another typical embodiment of the present invention, a method for preparing a self-degradable anti-leakage plugging material is also provided. The preparation method includes: step S1, according to any one of the above-mentioned raw materials for the self-degradable anti-leakage plugging material Proportioning and preparing a raw material mixture; step S2, reacting the raw material mixture under heating and pressure to obtain a self-degradation leak-proof and plugging material.

[0029] The self-degradation anti-leakage plugging material precursor obtained by the polymerization reaction of the above-mentioned raw materials in the above ratio under heating and pressure, and then undergoes a granulation step to form a granular self-degradation anti-leakage plugging material with a specific particle size, It has good compressive strength and can withstand strong compressive shearing force; it has excellent plugging performance and can effectively seal the lost zone; at t...

Embodiment 1

[0042] The formula is: tap water 1000kg, acrylic acid monomer 80kg, water-soluble starch 160kg, ammonium persulfate 8kg, KH-570 silane coupling agent 4kg.

[0043] Preparation:

[0044] ①Add 1000kg of water at a temperature of 30°C to a ceramic mixing tank, then add 80kg of acrylic acid, stir evenly, add 160kg of water-soluble starch while stirring, stir for 20 minutes, and then add 8kg of ammonium persulfate and 4kg of KH-570 silane coupling agent , continue stirring for 20 minutes.

[0045] ②Pump the above-mentioned stirred raw materials into a stainless steel reaction kettle with a pressure resistance of 0.4Mpa, seal and heat to 70°C, and react for 10 hours.

[0046] ③Extrude the product in the stainless steel reaction kettle, and process it into a granular product with a diameter of 0.5-5mm by using a twin-screw plastic extruder to obtain a finished product.

[0047] During application, the self-degradable anti-leakage plugging agent for workover is mixed into the workov...

Embodiment 2

[0049] The formula is: tap water 1000kg, acrylic acid monomer 120kg, water-soluble starch 160kg, ammonium persulfate 8kg, KH-570 silane coupling agent 4kg.

[0050] Preparation:

[0051] ①Add 1000kg of water at 27°C to the ceramic mixing tank, then add 120kg of acrylic acid, stir evenly, add 160kg of water-soluble starch while stirring, stir for 20 minutes, then add 8kg of ammonium persulfate and 4kg of KH-570 silane coupling agent , continue stirring for 20 minutes.

[0052] ②Pump the above-mentioned stirred raw materials into a stainless steel reaction kettle with a pressure resistance of 0.4Mpa, seal and heat to 70°C, and react for 10 hours.

[0053] ③Extrude the product in the stainless steel reaction kettle, and process it into a granular product with a diameter of 0.5-5mm by using a twin-screw plastic extruder to obtain a finished product.

[0054] During application, the self-degradable anti-leakage plugging agent for workover is mixed into the workover fluid, and inj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com