High elasticity graphene membrane

A graphene film and high elasticity technology, applied in the field of new elastic graphene film material and its preparation, can solve the problems of troublesome operation, the graphene film does not have high stretching and high wrinkles, and the flexibility is not clear, and achieves a high level of tensile strength. Elasticity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of highly elastic graphene film is prepared by the following method:

[0022] (1) Add 20 parts by weight of ethyl acetate to 100 parts by weight of a graphene oxide aqueous solution with a concentration of 1 mg / mL; after ultrasonic dispersion, pour it on a mold plate, and dry it naturally under a relative air humidity of 70% to form an oxide Graphene film, make most (>90wt%) solvent volatilization, then remove remaining solvent at 60 ℃;

[0023] (2) Reducing the graphene oxide film treated in step 1 in hydroiodic acid solution. The HI content of the hydroiodic acid solution is shown in Table 1, the reduction temperature is 70°C, and the reduction time is 8h.

[0024] (3) The reduced graphene film was soaked in ethanol to wash off the surface hydroiodic acid, and then dried naturally to obtain a graphene elastic film.

[0025] Table 1: Properties of products at different hydriodic acid concentrations

[0026]

[0027] As can be seen from the above table, und...

Embodiment 2

[0029] A kind of highly elastic graphene film is prepared by the following method:

[0030] (1) Add 100 parts by weight of petroleum ether to 100 parts by weight of graphene oxide ethanol solution with a concentration of 2 mg / mL; after ultrasonic dispersion, pour it on the mold plate, and let it dry naturally under the relative air humidity of 80%. Graphene film, so that most (>90wt%) of the solvent is volatilized, and then the remaining solvent is removed at 100 ° C;

[0031] (2) Reducing the graphene oxide film treated in step 1 in hydroiodic acid solution. The HI content of the hydroiodic acid aqueous solution is 20 wt%, the reduction temperature is 100 degrees Celsius, and the reduction time is 4 hours.

[0032] (3) The reduced graphene film was soaked in ethanol to wash off the surface hydroiodic acid, and then dried naturally to obtain a graphene elastic film.

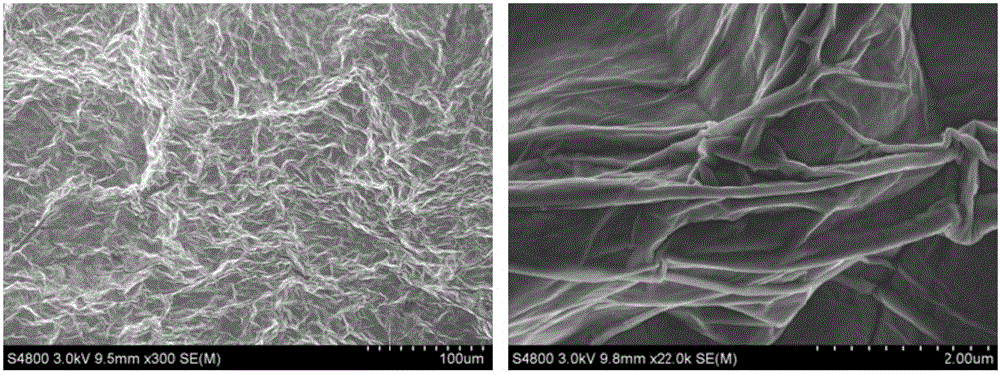

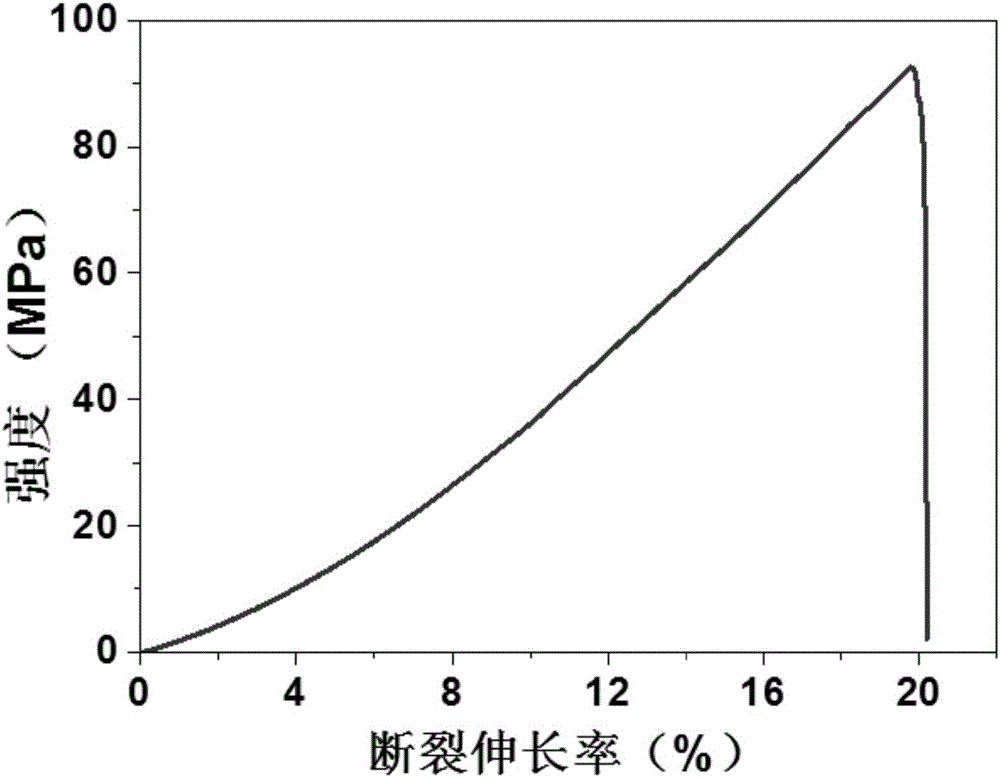

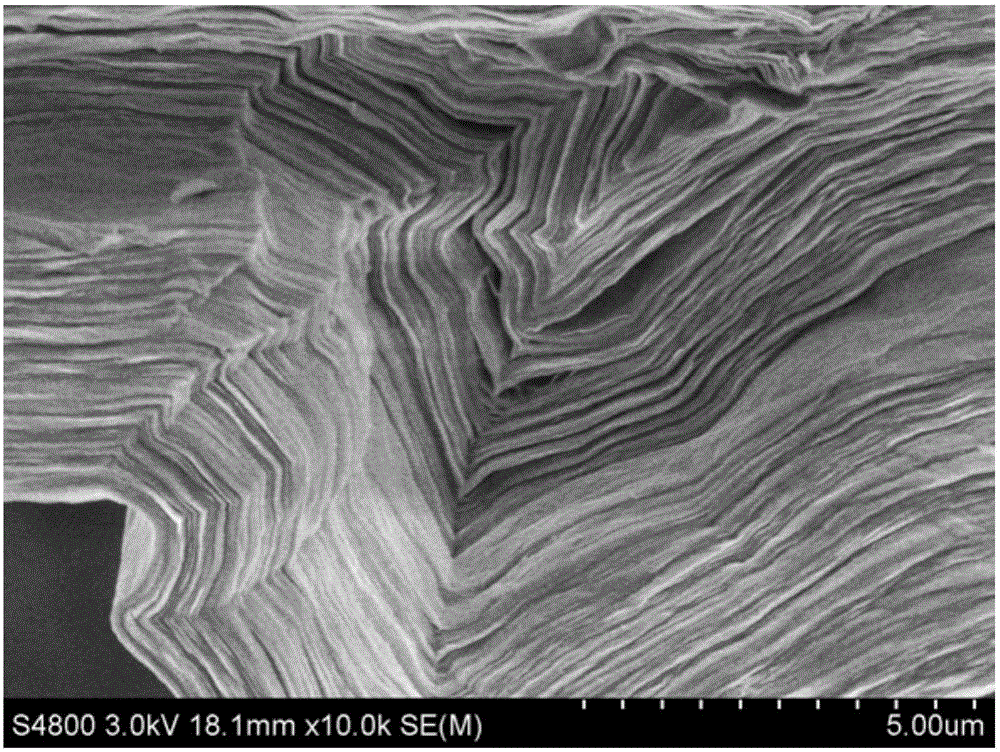

[0033] Such as figure 1 , 3 , 4, the highly elastic graphene film is formed by cross-linking a multilayer ...

Embodiment 3

[0035] A kind of highly elastic graphene film is prepared by the following method:

[0036] (1) Add 40 parts by weight of ethyl acetate to the graphene oxide DMF solution of 1.8 mg / mL at a concentration of 100 parts by weight; after ultrasonic dispersion, pour it on the mold plate and let it dry naturally under 50% relative air humidity Forming a graphene oxide film, making most (>90wt%) solvent volatilization, and then removing the remaining solvent at 80°C;

[0037] (2) Reducing the graphene oxide film treated in step 1 in hydroiodic acid solution. The HI content of the hydroiodic acid aqueous solution is 20 wt%, the reduction temperature is 100 degrees Celsius, and the reduction time is 4 hours.

[0038] (3) The reduced graphene film was soaked in ethanol to wash off the surface hydroiodic acid, and then dried naturally to obtain a graphene elastic film.

[0039] This highly flexible graphene thermally conductive film can withstand repeated bending for more than 100,000 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com