A device and method for converting methane using plasma

A plasma and methane technology, applied in chemical instruments and methods, inorganic chemistry, organic chemistry, etc., can solve problems such as inapplicable methane conversion, and achieve the effect of benefiting methane conversion, reducing costs and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

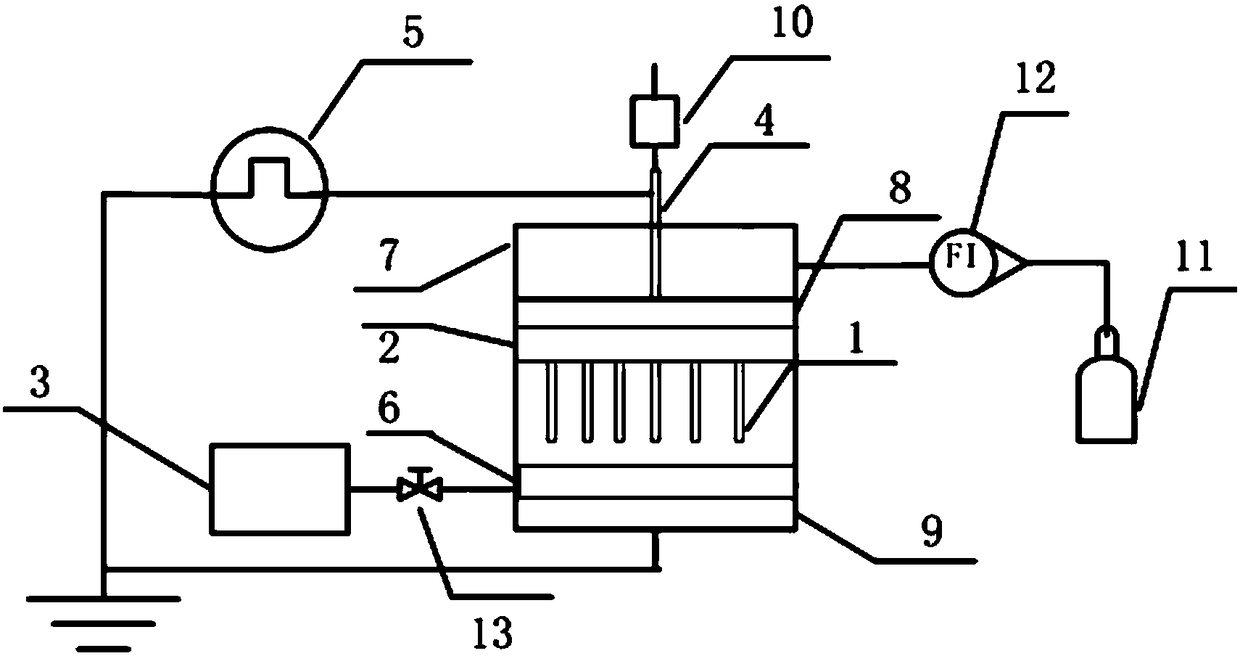

[0056] The multi-needle electrode array 1 adopts a single-needle electrode, the gap between the single-needle electrode and the lower metal base 6 is 4mm, the gas in the gas cylinder 11 is methane, and the gas flow rate is respectively set to 50ml / min, 100ml / min, and 150ml / min, 200ml / min, the working voltage is 20kV, the discharge frequency is 1000Hz, and the plasma discharge time is 10min. The plasma treats methane, collects methane cracking products, and the online measurement results of gas chromatography are as follows: figure 2 and image 3 shown. figure 2 Corresponding to the gaseous product yield and methane conversion percentage, the abscissa corresponds to the gas flow rate. figure 2 Indicates that the collected gaseous products are composed of H 2 、C 2 h 6 、C 2 h 4 and C 2 h 2 composition, in which the main product is H 2 and C 2 h 2 . The conversion rate and yield decreased with the increase of the gas flow rate. When the gas flow rate was 50ml / min, ...

Embodiment 2

[0058] The multi-needle electrode array 1 adopts a single-needle electrode, the gap between the single-needle electrode and the lower metal base 6 is 8mm, the gas in the gas cylinder 11 is methane, and the gas flow rate is set to 50ml / min, 100ml / min, and 150ml respectively / min, 200ml / min, the working voltage is 20kV, the discharge frequency is 1000Hz, and the plasma discharge time is 10min. The plasma treats methane, collects methane cracking products, and the online measurement results of gas chromatography are as follows: Figure 4 shown. Figure 4 The ordinate corresponds to the gaseous product yield and methane conversion percentage, and the abscissa corresponds to the gas flow rate. Depend on Figure 4 It can be seen that the collected gaseous products are composed of H 2 、C 2 h 6 、C 2 h 4 and C 2 h 2 composition, in which the main product is H 2 and C 2 h 2 . The conversion rate and yield decreased with the increase of the gas flow rate. When the gas flow ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com