Automatic working platform vertical-lifting device and control method thereof

A vertical lifting and working platform technology, applied in the direction of lifting devices, transportation and packaging, load hanging components, etc., can solve the problems of affecting rescue efficiency, reducing rescue efficiency, and large amount of control, so as to improve rescue work efficiency and reduce control Complexity, the effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific examples.

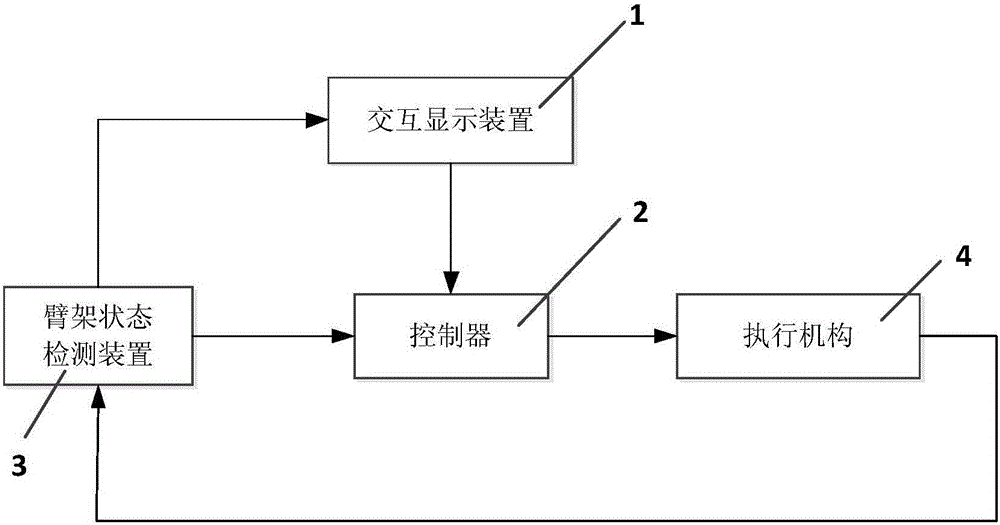

[0018] Such as figure 1 As shown, it is an automatic vertical lifting movement device for a working platform, including an interactive display device 1, a controller 2, a boom state monitoring device 3, and an actuator 4.

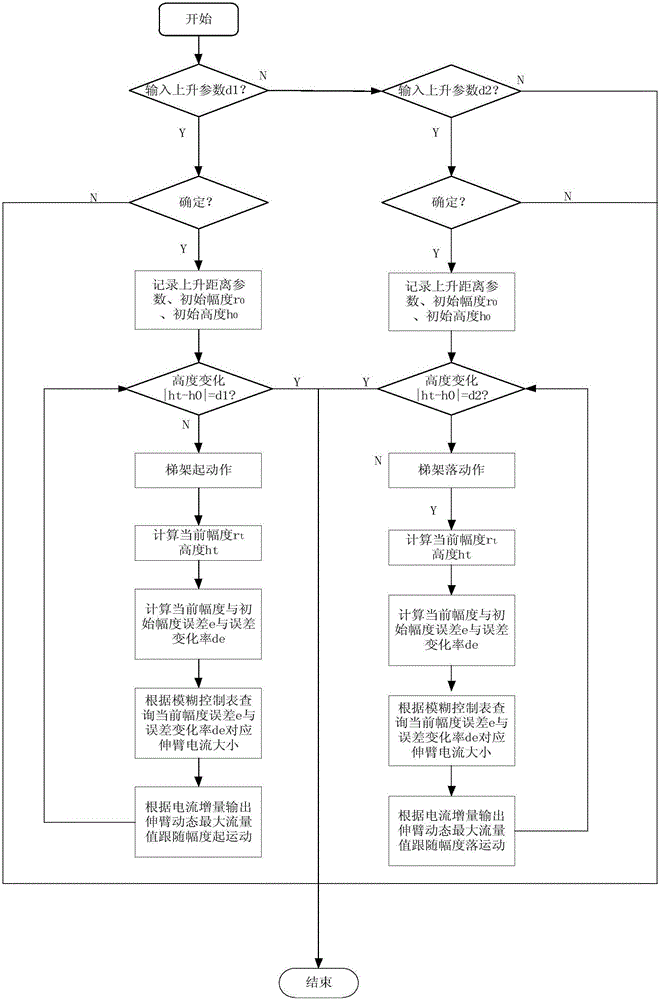

[0019] The device inputs the distance parameter of the working platform up or down to the interactive display device 1 and transmits it to the controller 2 through communication. The boom status monitoring device 3 transmits the boom length and angle information to the controller 2, and the controller 2 Calculate the real-time amplitude, altitude, altitude change, amplitude error and rate of change of amplitude error. The controller 2 automatically starts the rising or falling action according to the distance parameter: output a constant current value to the luffing valve of the actuator 4, and at the same time bring the amplitude error and the rate of cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com