Manufacturing method of filament-loop ground mat

A wire loop floor mat and a manufacturing method technology, applied in the field of floor mat manufacturing, can solve the problems of only being able to absorb, not being able to block larger objects, and being difficult to clean up debris, etc., so as to achieve easy cleaning, improve the anti-skid effect, and prevent There is an effect that water enters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

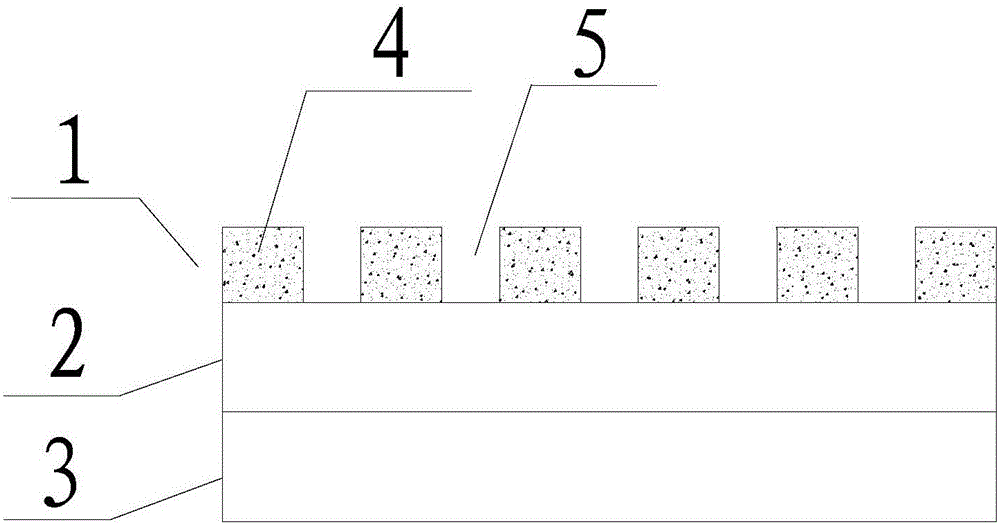

[0018] Such as figure 1 Shown, a kind of manufacture method of wire loop floor mat, comprises the following steps:

[0019] S1. First, mix 5kg of PVC raw materials and heat them into a molten state, then add them into the spinneret to process them into thread loops, and then immerse them in a water tank to cool and shape them to form the thread loop layer 1; the spinnerets use hyperbolic nozzles, which can be compared Good control of the shear velocity of the melt and a source of greater pressure difference.

[0020] S2. Cut the loop layer 1 produced in step S1 into a plurality of loop strips 4 of the same size by a shearing machine; in this embodiment, each loop strip 4 has a width of 3 cm and a thickness of 1 cm.

[0021] S3. Put 3kg of PVC raw materials into the barrel and mix them. After mixing, add them to the disperser and stir evenly....

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com