Control Method of Jet Polishing Surface Shape Error Based on Variable Removal Function

An error control and surface polishing technology, applied in program control, computer control, general control system, etc., to reduce vibration, improve removal convergence efficiency, and reduce surface error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

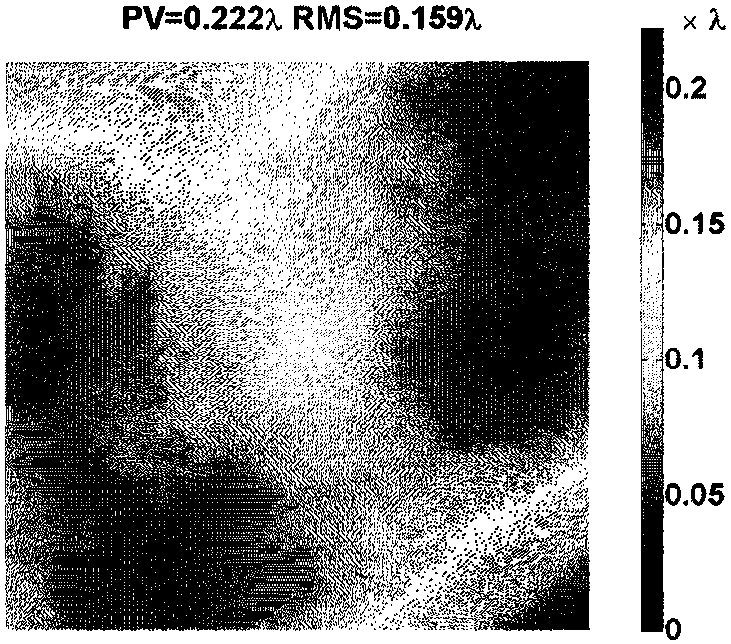

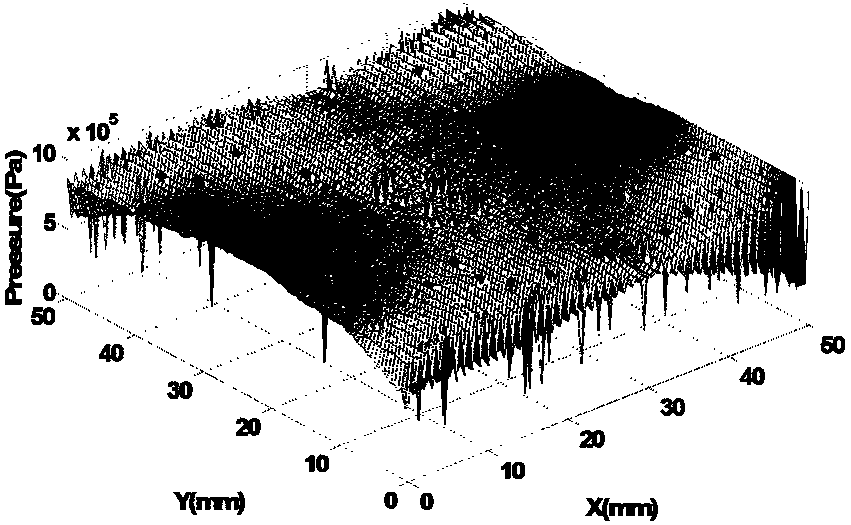

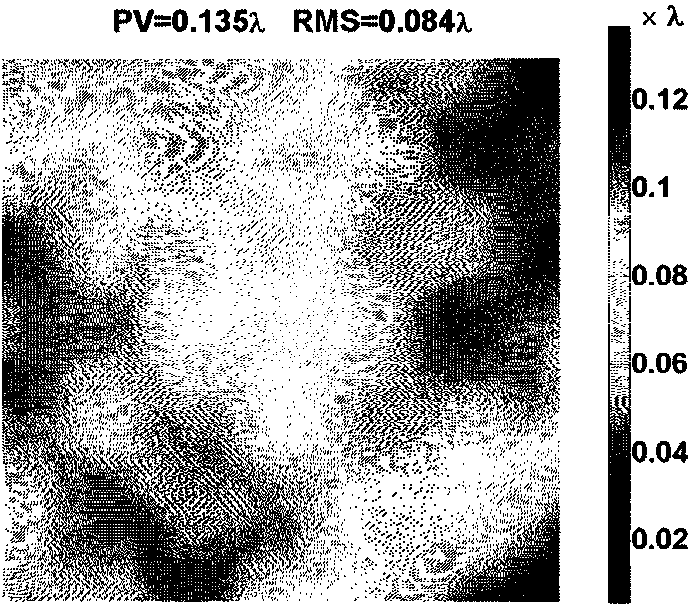

[0024] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments, with reference to formulas and accompanying drawings. The invention realizes the control of the removal function by regulating the polishing process parameter of nozzle pressure.

[0025] The polishing equipment is an ordinary jet polishing machine tool, and the basic processing parameters are: the maximum feed speed of the machine tool =4000mm / min, nozzle inclination θ = 20°, nozzle speed 1000r / min, the polishing process of the machine tool maintains a constant feed rate =50mm / min, the distance between the programmed position of the polishing head and the surface of the workpiece is 50mm, the diameter of the nozzle is 1mm, and the upper limit of the nozzle pressure is =1MPa, the lower limit is =0.286MPa. The processed test piece is a K9 workpiece with a diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com