A kind of online welding method of circulating fan impeller

A welding method and technology for circulating fans, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of fan impeller cracks, affecting production needs, short service time, etc., to reduce the thickness of the weld and delay the crack time. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is further described as follows:

[0018] An online welding method for a circulating fan impeller, comprising the following steps in sequence:

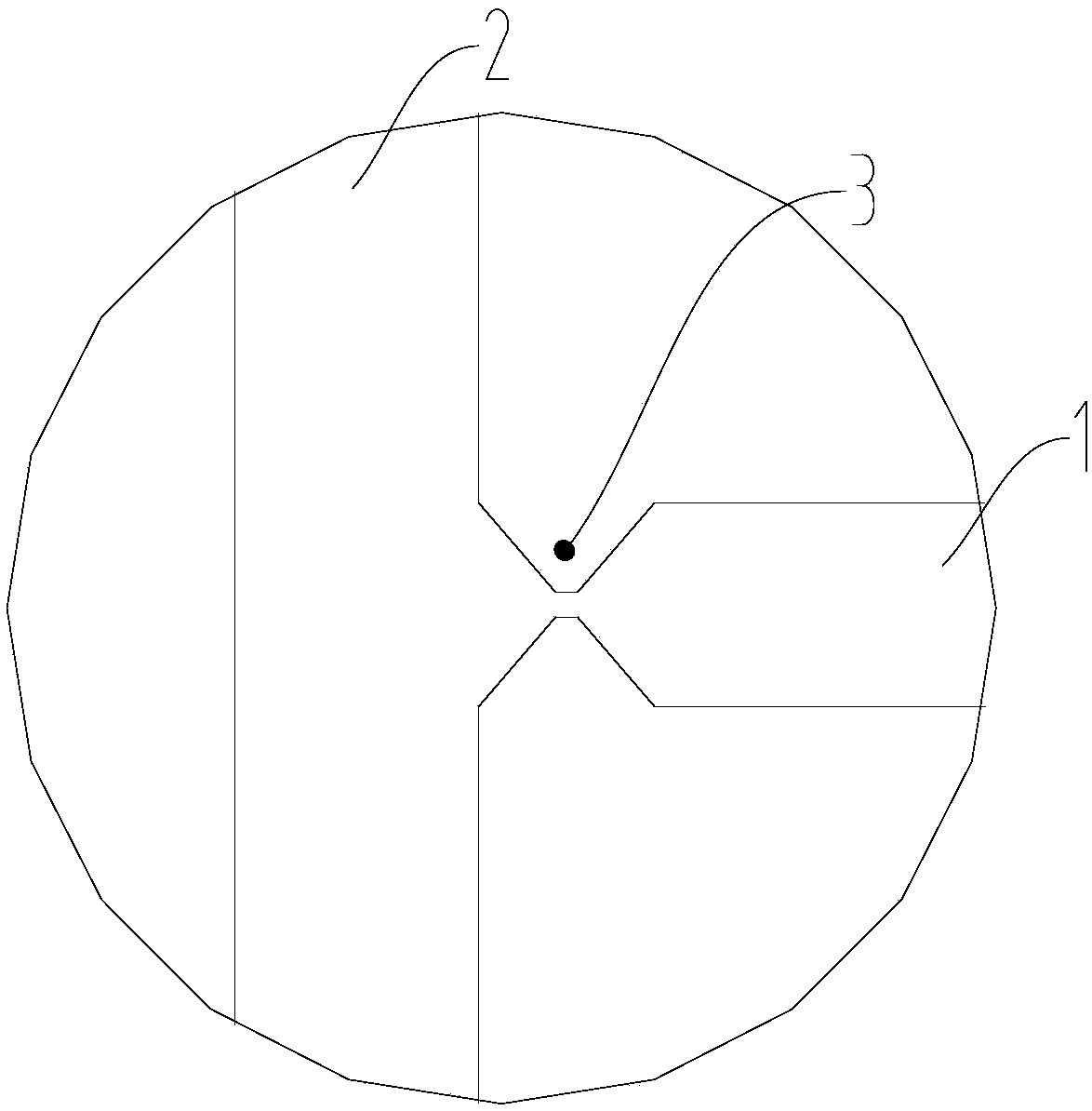

[0019] a. Crack removal: open a U-shaped groove groove 3 at the end where the blade 1 is connected to the hub 2 to remove cracks;

[0020] b. Welding: At least two layers of weld bead are used for welding, and the overlapping surface between two adjacent layers of weld bead is not less than 1 / 3 of the width of the outer bead; each layer of weld bead is divided into three sections or two sections for desoldering , the joints between two adjacent sections of welds in each layer of welds should be staggered by at least 30mm.

[0021] Insufficient throat depth or insufficient penetration of the weld bead will increase the probability of longitudinal cracks, and the weld bead usually plays a key role in bearing the tensile and compressive stresses at both ends. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com