Arc surface adjustable feeding method and equipment for laser machine

An adjustable laser machine technology, applied in the mechanical field, can solve the problems of reduced laser energy density, reduced die-cutting accuracy, and affecting the quality of laser die-cutting, achieving the effects of reduced divergence, reduced divergence, and improved equipment versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

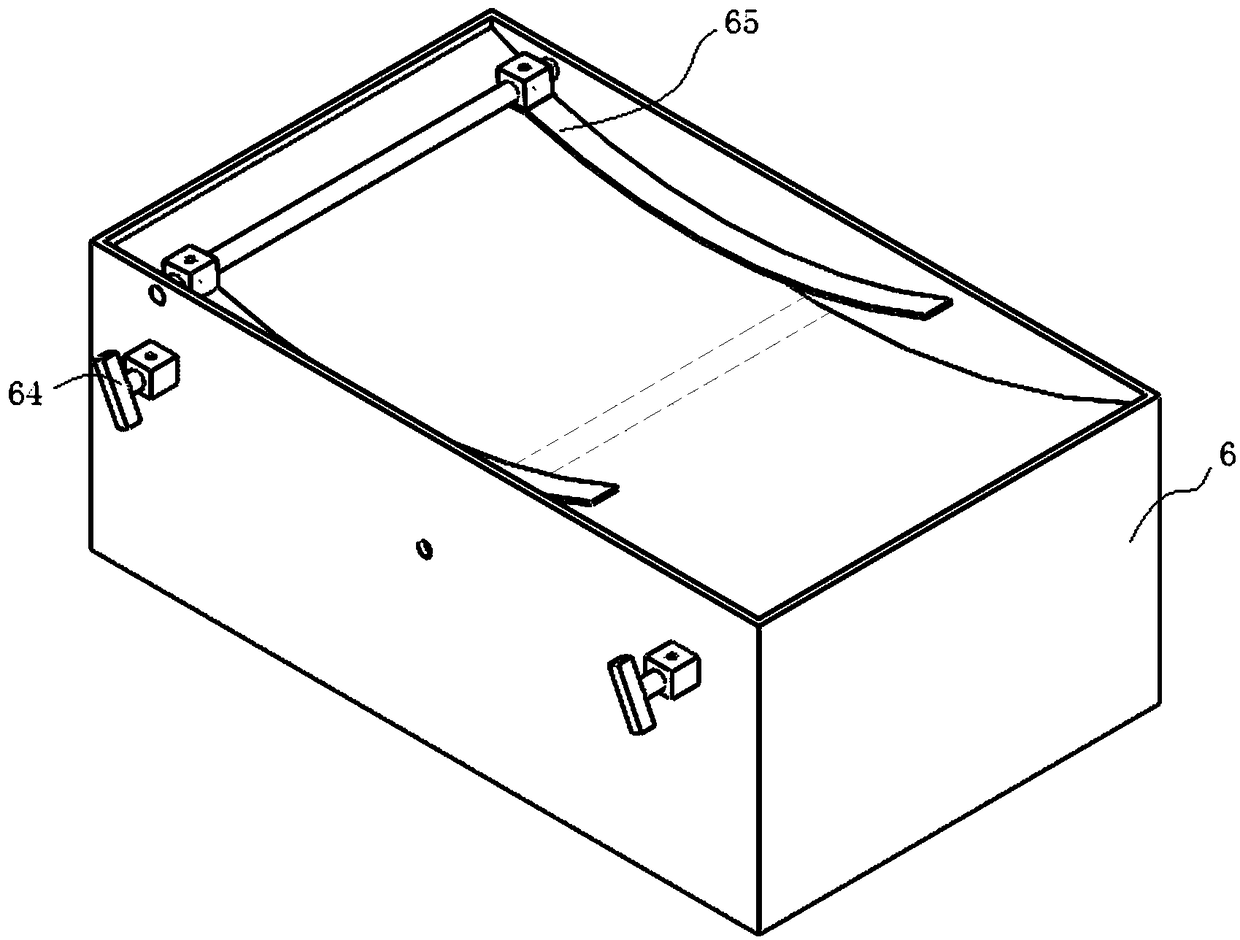

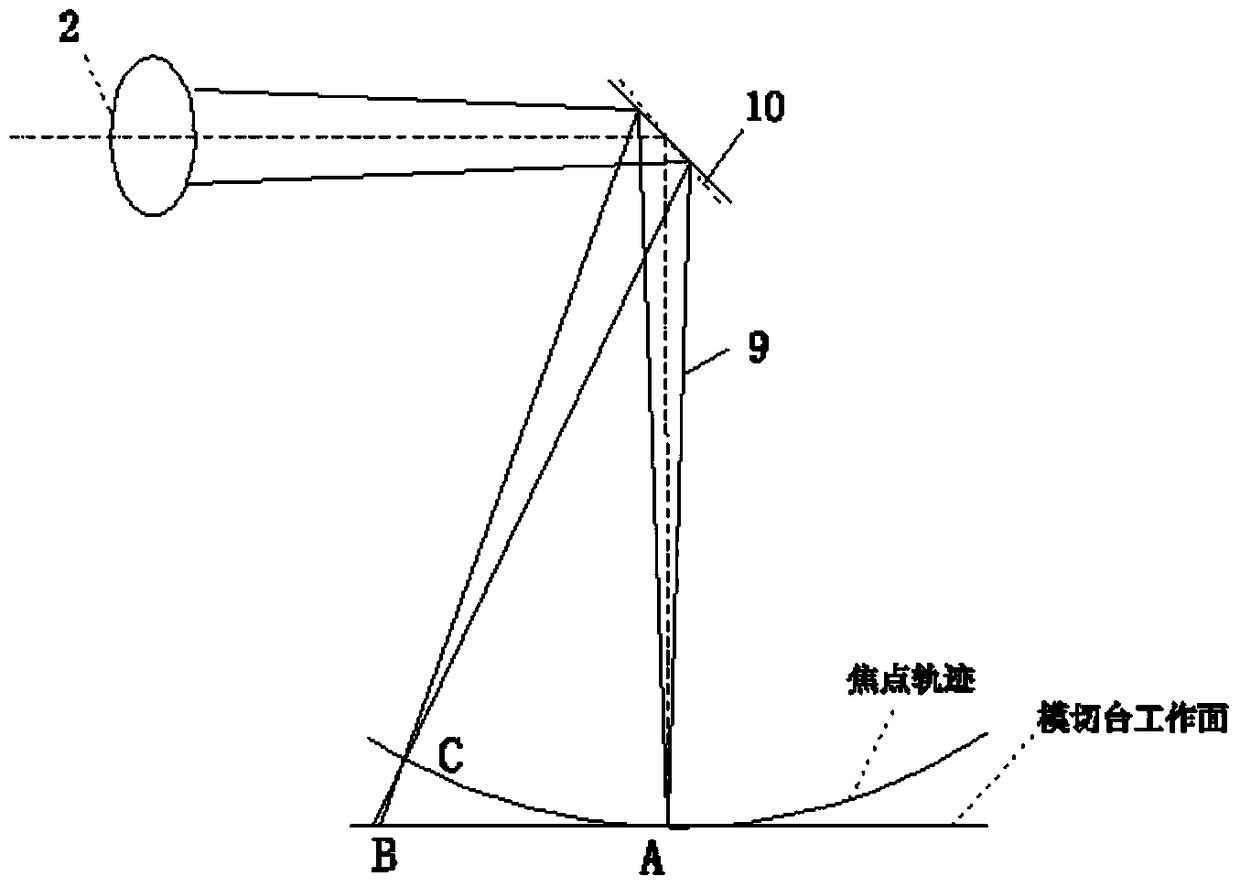

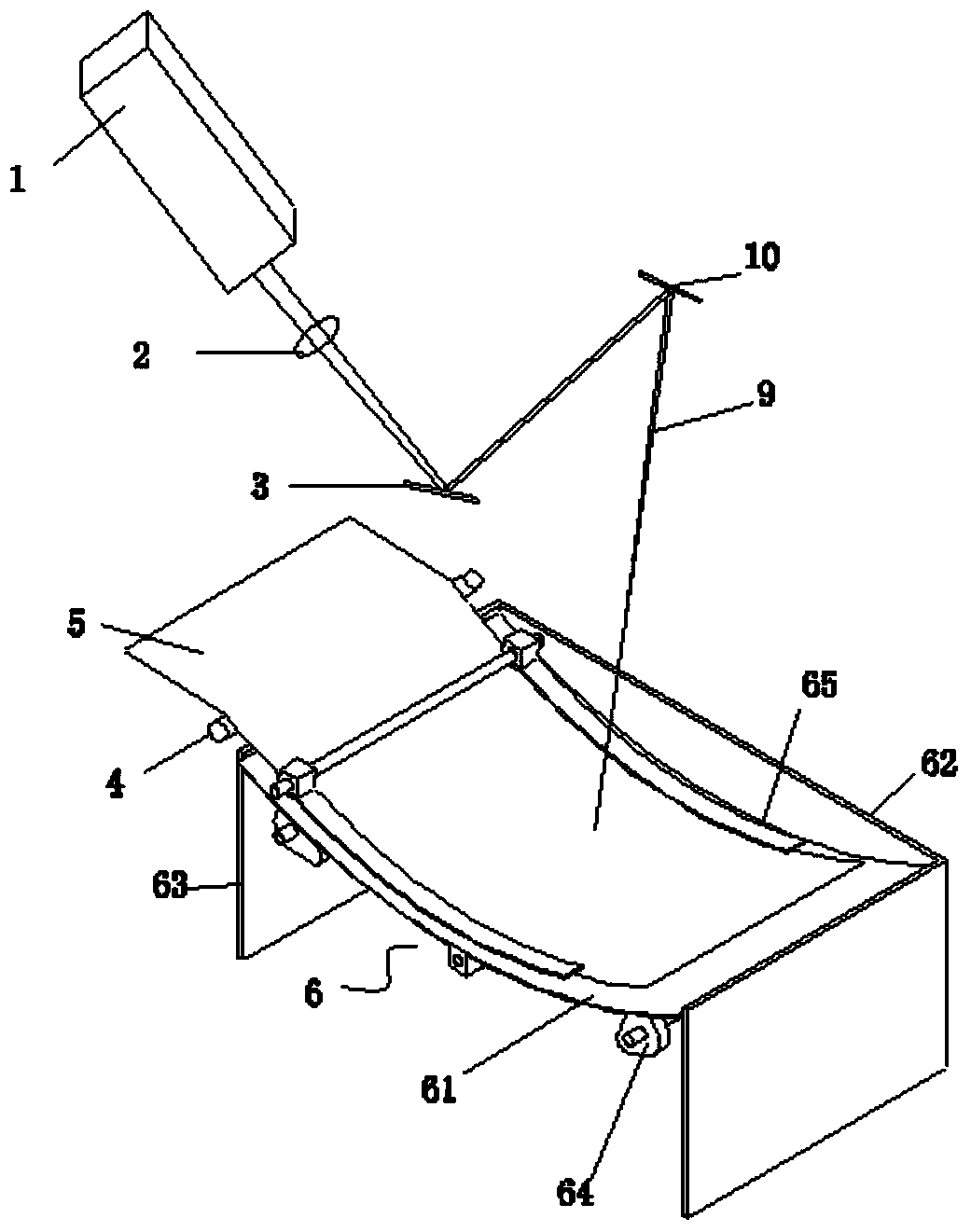

[0039] Such as figure 2 Shown is a schematic diagram of the structure of the arc-adjustable feeding equipment for laser machines provided by the present invention. It should be noted that the laser machine of the present invention can be a laser die-cutting machine working in a post-lens scanning mode, or It is a laser cutting machine or a laser engraving machine. That is, the equipment of the present invention is suitable for a laser die cutting machine, or a laser cutting machine, or a laser engraving machine that works in a scanning mode after a lens, but the present invention only uses a curved surface. As an example, the adjustable conveying equipment is used in a laser die cutting machine, and its structure is described.

[0040] by figure 2 It can be seen that the arc-surface adjustable conveying equipment of the present invention includes: a die-cutting table 6 with a arc-shaped upper surface for supporting the material 5 to be die-cut; used to transport the material 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com