Cropping locating jig capable of preventing cropping pollution, and dust exhaust structure and method thereof

A positioning fixture and cutting technology, which is applied in the direction of chemical instruments and methods, cleaning methods and tools, manufacturing tools, etc., can solve the problems of poor dust removal effect of the fixture 6, polluted chips, and unsmooth dust exhaust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations. The basic principles of the present invention defined in the following description can be applied to other embodiments, variations, improvements, equivalents and other technical solutions without departing from the spirit and scope of the present invention.

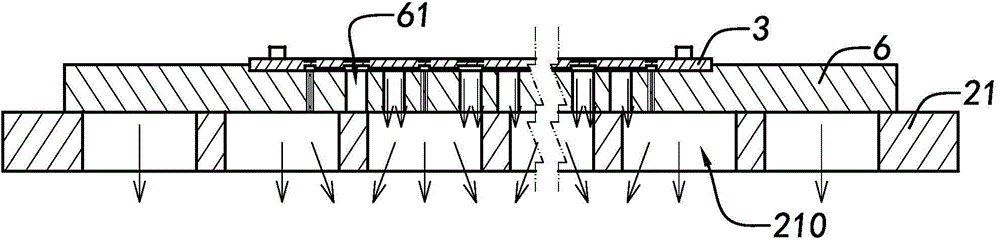

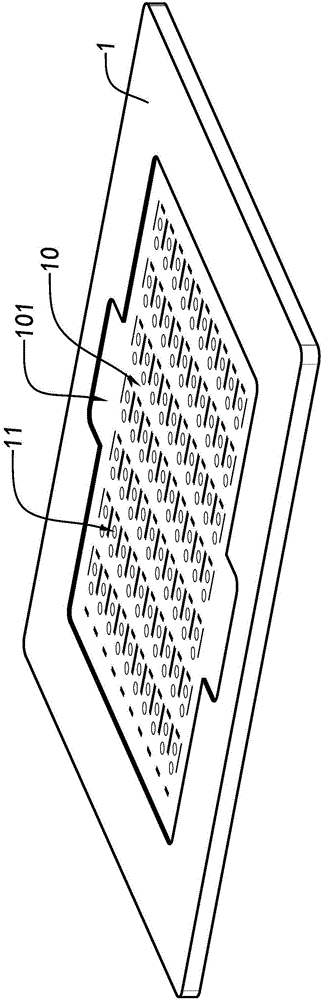

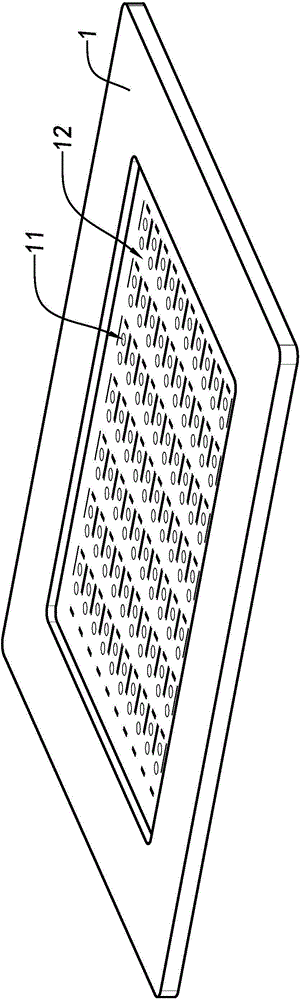

[0046] picture 3-7 shows a schematic diagram of a cutting and positioning fixture 1 of the present invention in use picture , which is also a schematic representation of a dust discharge structure of the present invention picture . A workpiece 3 to be processed is suitable for being installed on the jig 1, and an air suction device 2 is suitable for cooperating with the jig 1 to carry out an air suction operation, and discharges the dust generated duri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com