Pipeline hole opening device and pipeline hole opening method

A pipeline drilling equipment and pipeline technology, which is applied in the direction of drilling/drilling equipment, mechanical equipment, boring/drilling, etc., and can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

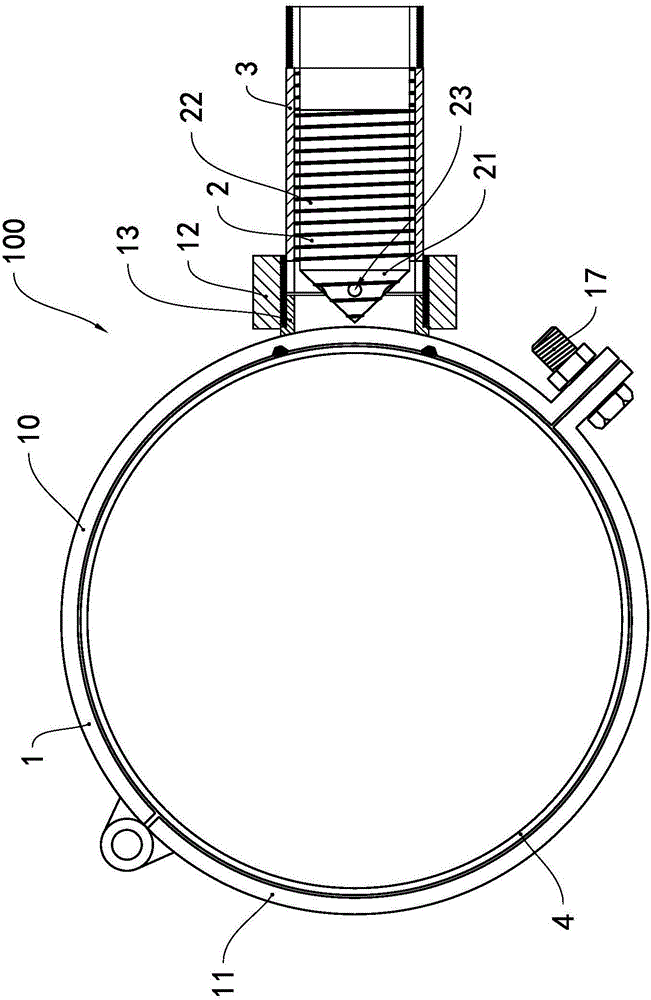

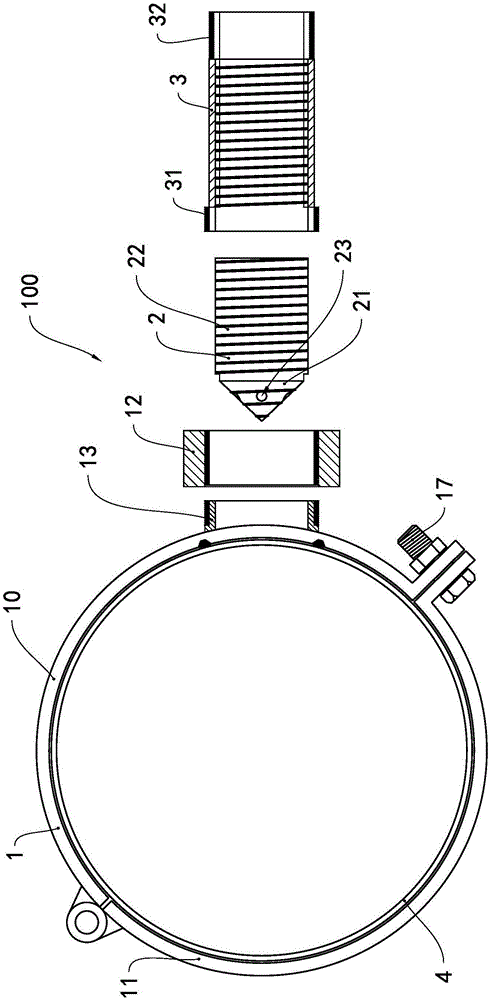

[0034] See figure 1 , The pipe drilling equipment 100 of this embodiment includes a collar 1, a drill bit 2, and a jacking casing 3. The ferrule 1 is fixedly sleeved on the outside of the pipeline 4, the quick-connect buckle 12 fixedly connects the jacking casing 3 with the ferrule 1, and the drill bit 2 is rotatably assembled in the jacking casing 3.

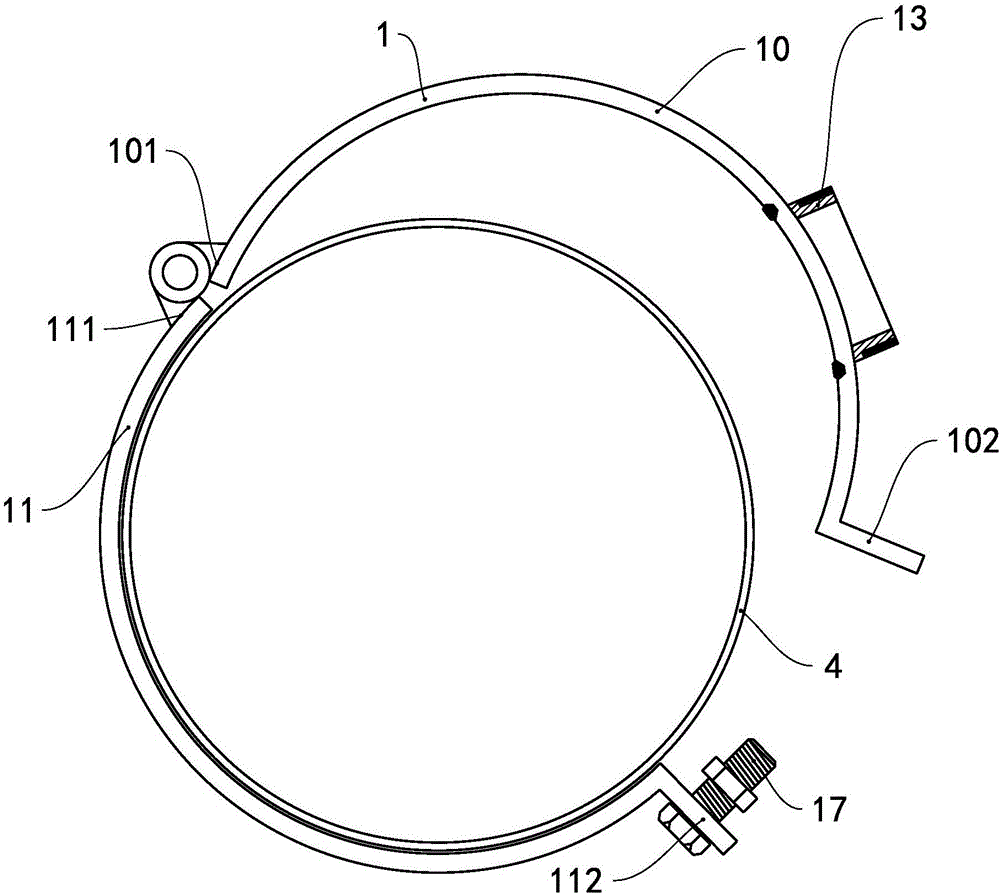

[0035] See figure 2 versus Figure 5 , The hoop 1 includes a first part 10, a second part 11, a quick interface 13, a quick coupling 12 and an opening 14. The shape of the ferrule 1 is the same as that of the pipe, both of which are round. In this embodiment, the hoop 1 is divided into a first part 10 and a second part 11 along the diameter. The first end 101 of the first part 10 and the first end 111 of the second part 11 are movably connected to each other for rotation, and the second end 102 of the first part and the second end 112 of the second part can be fixed by The bolts 17 are fixedly connected to each other to fix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com