High-speed blanking machine for blanking spring pads

A punching machine and spring pad technology, applied in the field of spring pad production equipment, can solve the problems of complex equipment structure, increased production cost, low punching efficiency, etc., and achieve the effect of full automatic structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

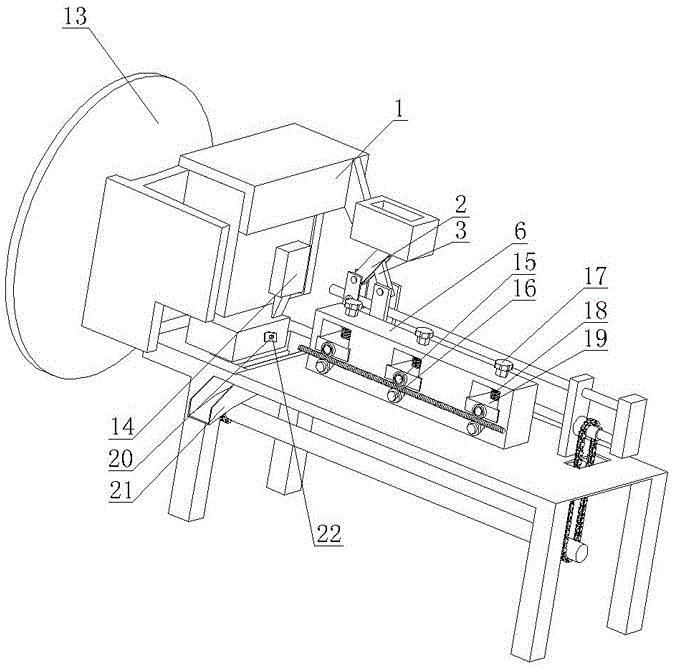

[0015] As shown in the figure, a high-speed punching machine for punching spring pads disclosed by the present invention includes a frame 12 on which a tool holder 1 and a driving motor are installed, and the driving motor is connected to a flywheel 13, and the flywheel 13 passes through the The eccentric mechanism is connected with the knife seat 1, and a cutter 14 is arranged on the knife seat 1, a stopper 20 is arranged below the cutter 14, a blanking channel 21 is provided on the frame 12, and the blanking channel 21 is placed on the stopper 20, there is also a spring piece 22 at the punching position of the stopper 20, which is convenient for spring pads that have been punched into the blanking channel 21. The knife seat 1 is hinged with the first connecting rod 2, and the first connecting rod The rod 2 is hinged with the second connecting rod 3, the frame 12 is provided with a fixed seat 4, and the fixed seat 4 is equipped with a movable guide rod 5 and a worm 7, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com