A double-station unstacking and loading device

A dual-station, material table technology, applied in positioning devices, storage devices, feeding devices, etc., can solve problems such as affecting feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

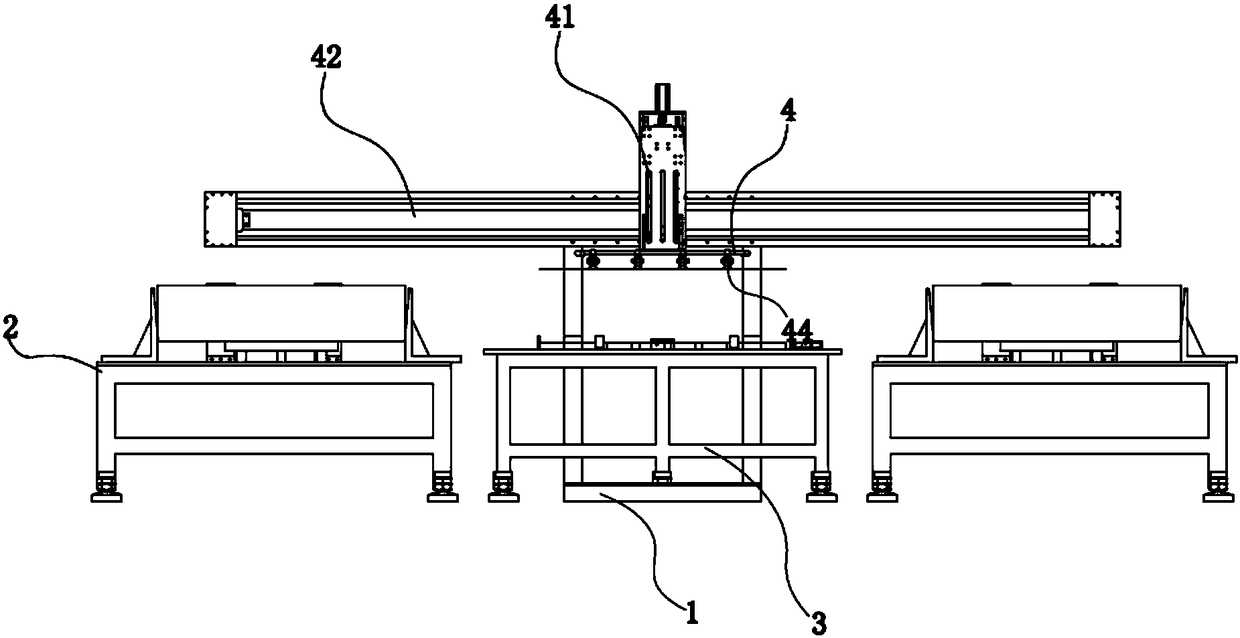

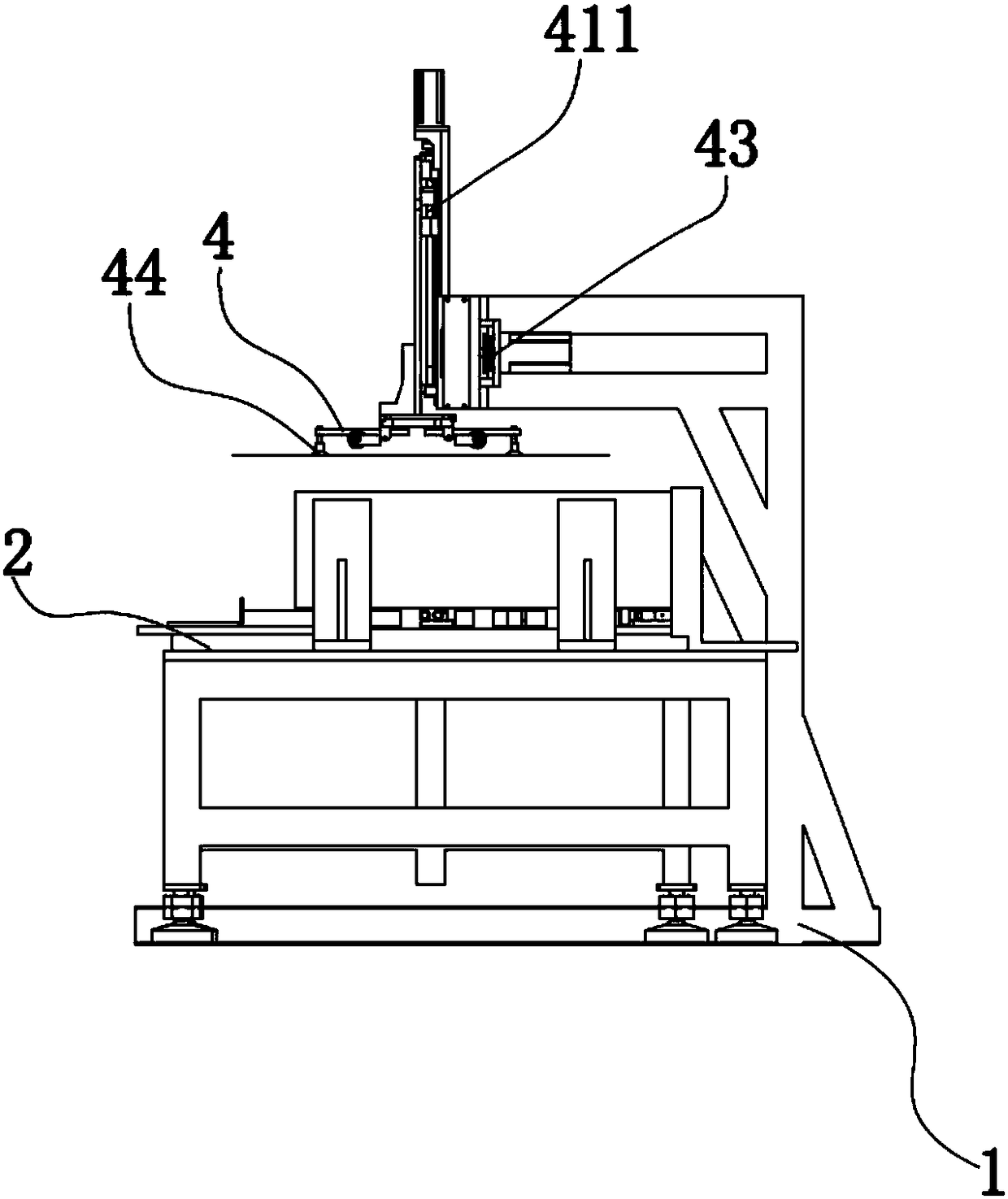

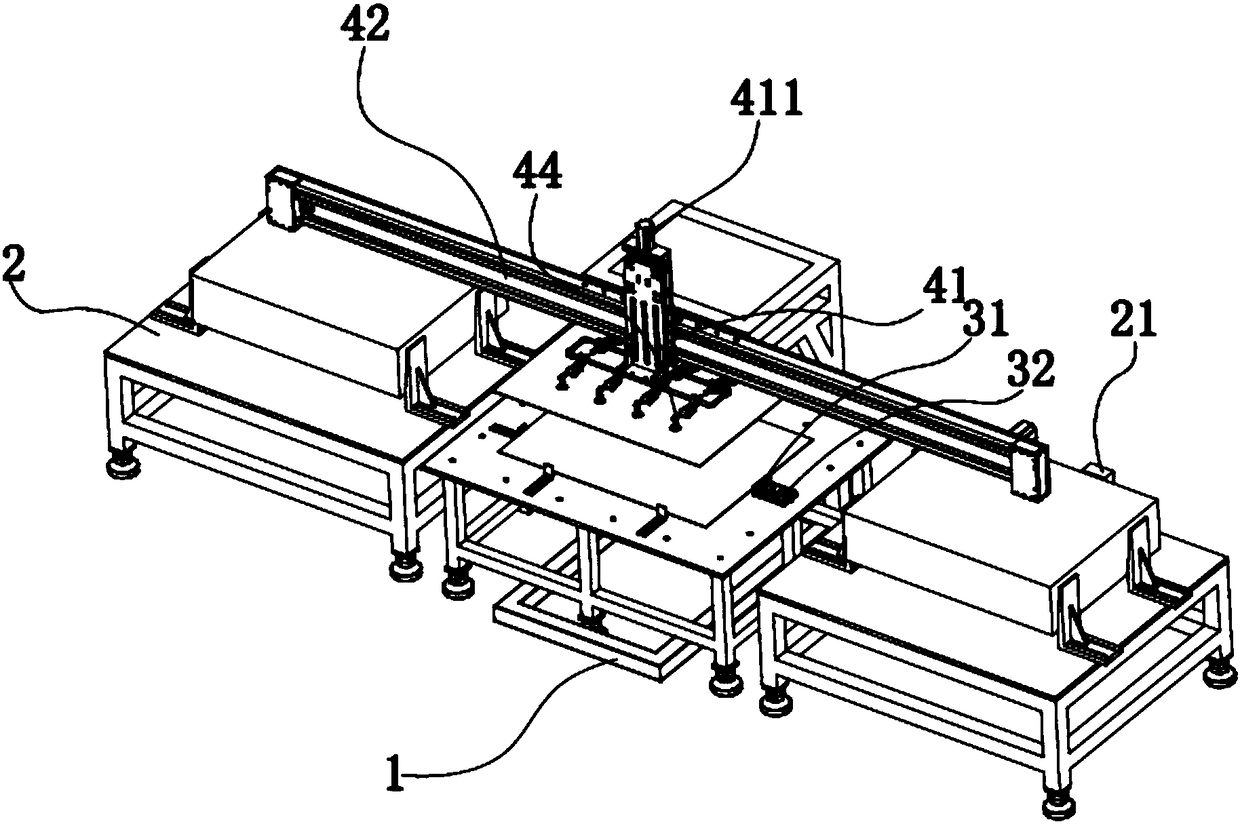

[0029] In order to achieve the purpose of the present invention, as Figure 1-3 As shown, in some embodiments of a double-station unstacking and feeding device of the present invention, it includes: a frame 1; two loading platforms 2, which are arranged symmetrically, and the two loading platforms 2 are fixedly installed On the bottom of the frame 1, a spreader 21 is arranged on the feeding platform 2; a positioning material platform 3 is arranged between the two loading platforms 2, and the positioning material platform 3 is fixedly installed on the bottom of the frame 1 Pick up manipulator 4, it is installed on the first guide rail 41 and is driven to move along the vertical direction by the second driving part 411 (motor or cylinder etc.), and the first guide rail 41 is slidably connected on the second guide rail 42 simultaneously, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com