Intelligent-measurement shaping device

A shaping device and intelligent measurement technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of inaccurate shaping, unstable downward movement, and easy deviation, and achieve the effect of high shaping accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

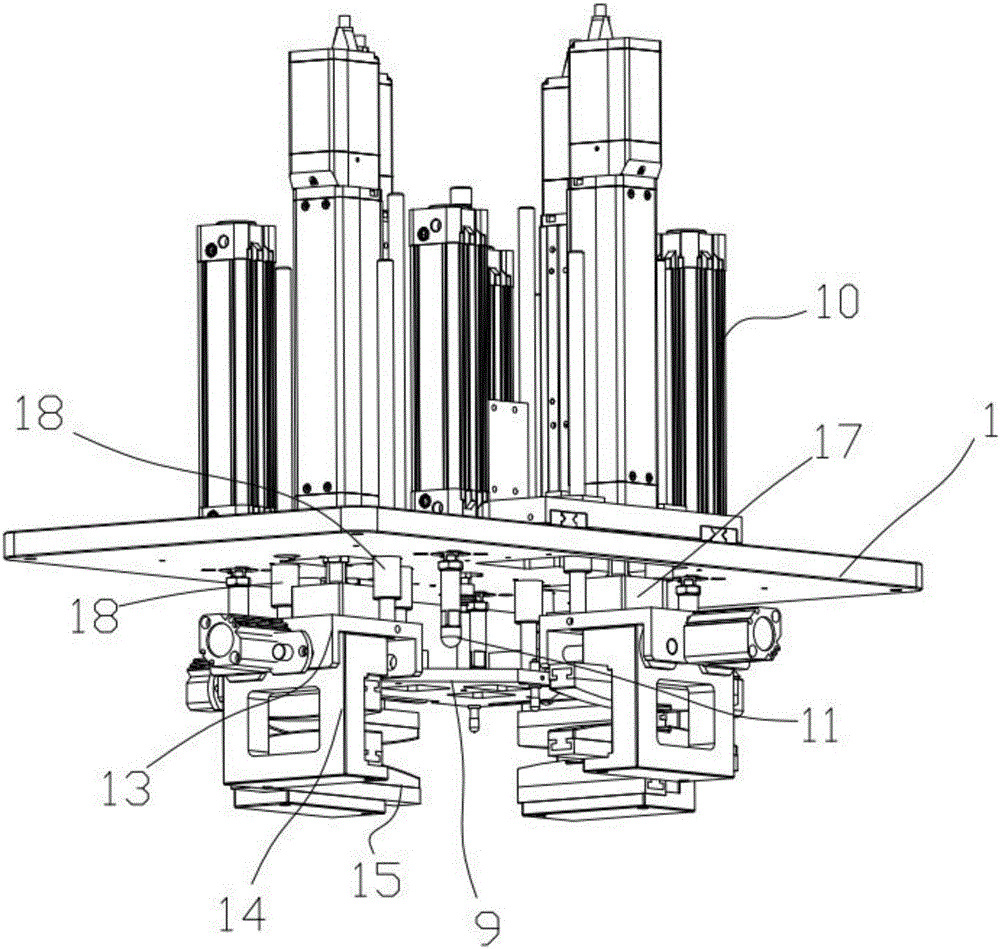

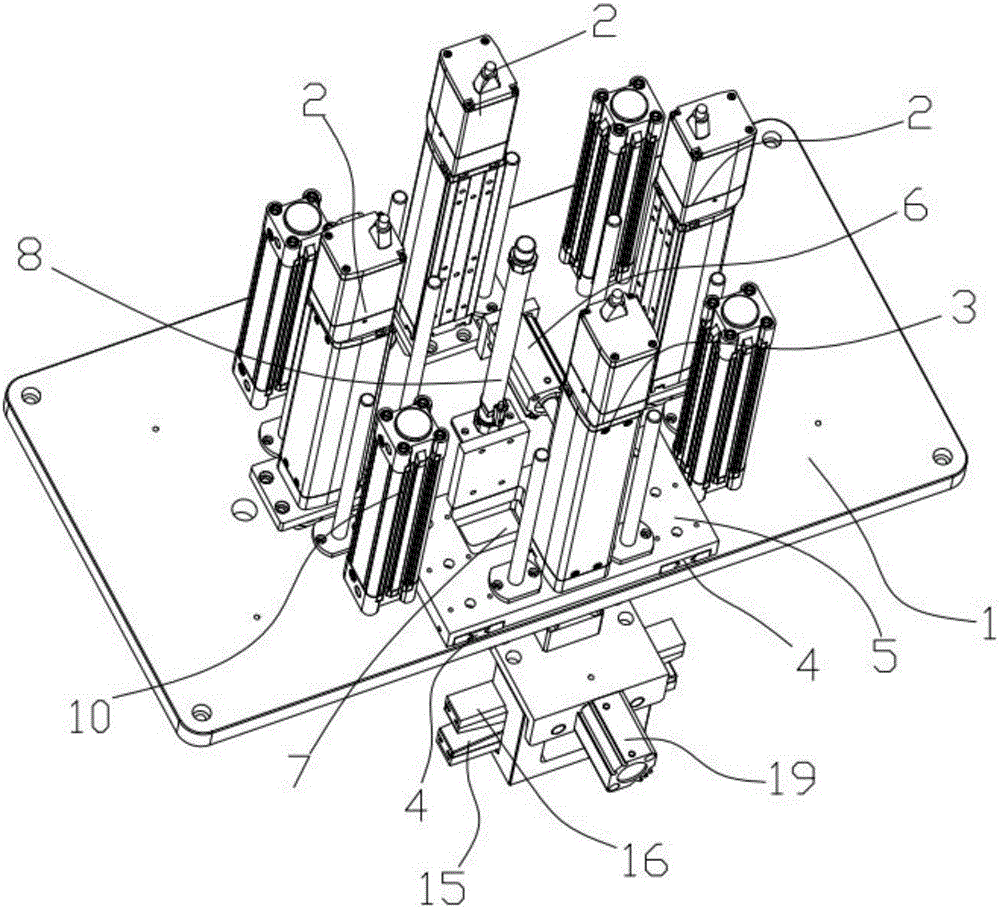

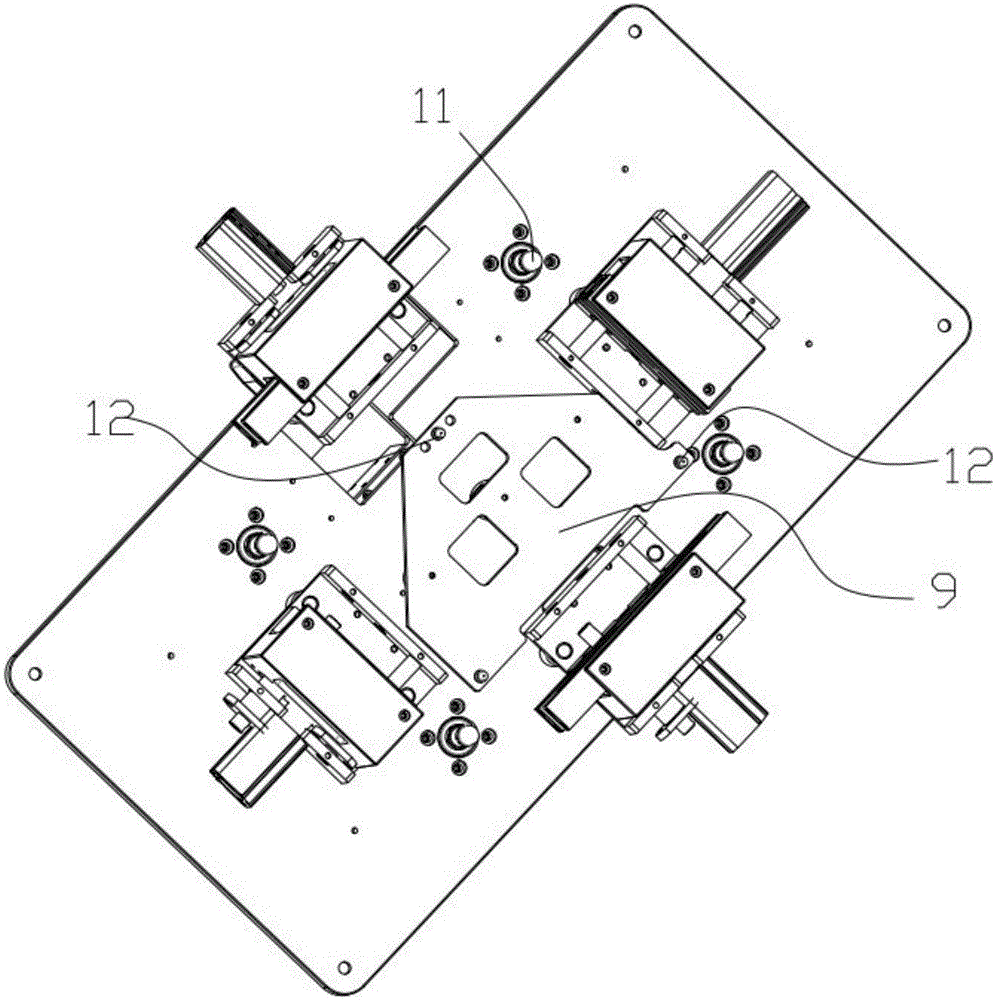

[0015] Such as figure 1 , figure 2 , image 3 As shown, the present invention proposes an intelligent measuring and shaping device, including a support plate 1, three fixed cylinders 2 and one movable cylinder 3 are arranged on the support plate 1, and the fixed cylinder 2 is fixed on the support plate 1 And the output end passes through the support plate 1;

[0016] In order to be more convenient for feeding materials, the movable cylinder 3 can be moved out of the position to load materials. The structure is that two slide rails 4 are arranged on both sides of the support plate 1 where the movable cylinder 3 is located, and a slide rail 4 is clamped on the slide rail 4. plate 5, the sliding plate 5 is connected with a horizontal cylinder 6, the movable cylinder 3 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com