Preparation method for g-C3N4/Zn3(VO4)2 composite photocatalyst with visible-light activity

A technology of VO4 and catalyst, which is applied in the field of preparation of g-C3N4/Zn32 composite photocatalyst, achieves good degradation effect, is suitable for mass production and popularization, and has mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 0.1 g of g-C respectively 3 N 4 and 0.0226 g of Zn 3 (OH) 2 V 2 o 7 2H 2 O, then add 50 mL of deionized water together and stir for 0.5 h, the solution is rotary evaporated, dried in vacuum at 30 °C, and finally calcined at 300 °C for 2.0 h with a heating rate of 3 °C min -1 , get g-C 3 N 4 / Zn 3 (VO 4 ) 2 Sample, wherein the sample contains Zn 3 (VO 4 ) 2 The mass ratio is 20%. Zn 3 (OH) 2 V 2 o 7 2H 2 O is composed of nanosheets with a size of 80–200 nm intersecting to form a three-dimensional structure.

[0027] The photodegradation efficiency of rhodamine B dye was 60.13% under visible light for 5.0 h.

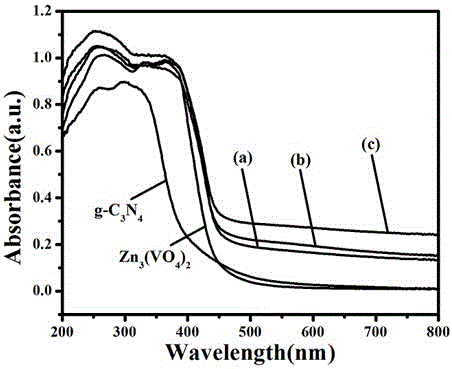

[0028] attached image 3 Curve (a) is the solid UV diagram of Example 1. It can be seen from the figure that, with g-C 3 N 4 and Zn 3 (VO 4 ) 2 In contrast, the light absorption of the composite photocatalyst has a red shift, and there is a strong absorption at 400-600 nm, indicating that the composite photocatalyst has a visible lig...

Embodiment 2

[0030] Weigh 1.0 g of g-C respectively 3 N 4 and 0.0113 g Zn 3 (OH) 2 V 2 o 7 2H 2 O, where Zn 3 (OH) 2 V 2 o 7 2H 2 O is composed of nanosheets with a size of 80–200 nm intersecting to form a three-dimensional structure. Add 100 mL of deionized water and stir for 3.5 h. The solution is rotary evaporated, dried at 40 °C, and finally calcined at 350 °C for 2.5 h. The heating rate is 4 ℃·min -1 , get g-C 3 N 4 / Zn 3 (VO 4 ) 2 Sample, wherein the sample contains Zn 3 (VO 4 ) 2 The mass ratio is 1%.

[0031] The photodegradation efficiency of rhodamine B dye was 65.47% under visible light for 5.0 h.

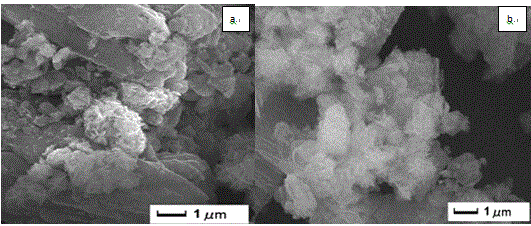

[0032] attached figure 1 (a) is the SEM image of Example 2.

Embodiment 3

[0034] Weigh 5.0 g of g-C respectively 3 N 4 and 0.1691 gZn 3 (OH) 2 V 2 o 7 2H 2 O, where Zn 3 (OH) 2 V 2 o 7 2H 2 O is composed of nanosheets with a size of 80–200 nm intersecting to form a three-dimensional structure. Add 150 mL of deionized water and stir for 6.0 h. Then the solution is rotary evaporated, dried at 50 °C, and finally calcined at 350 °C for 2.5 h. The heating rate is 5 ℃·min -1 , get g-C 3 N 4 / Zn 3 (VO 4 ) 2 Sample, wherein the sample contains Zn 3 (VO 4 ) 2 The mass ratio is 3%.

[0035] The photodegradation efficiency of rhodamine B dye was 76.27% under visible light for 5.0 h.

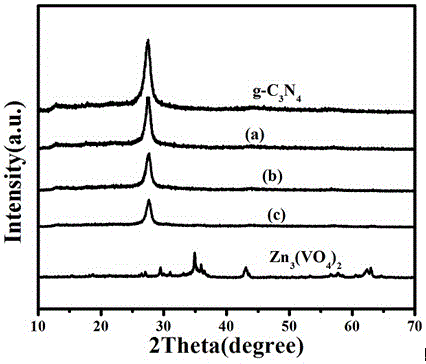

[0036] attached figure 2 Curve (a) is the XRD pattern of Example 3. It can be seen from the figure that the composite photocatalyst g-C 3 N 4 / Zn 3 (VO 4 ) 2 g-C appears in the diffraction peaks 3 N 4 and Zn 3 (VO 4 ) 2 The characteristic peaks, indicating that the two are well combined, due to the Zn 3 (VO 4 ) 2 The content is less, so the pea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com