First-aid bleeding stopping dressing and preparing method thereof

The technology of hemostatic dressing and chitosan fiber is applied in the field of first aid hemostatic dressing and its preparation, which can solve the problems of massive bleeding, contamination of surrounding skin or clothes, etc., and achieve the effects of promoting wound healing, coagulation and hemostasis wound healing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the non-woven absorbent pad of the second layer with low water absorption multiple: viscose fiber spunlace non-woven fabric, and the processing technology is the same as above.

[0033] The preparation method of the third layer of non-woven fabric absorbent pad with high water absorption multiple: mix viscose fiber and polyacrylate super absorbent fiber evenly, and then comb and spread it into a fiber web, and through the puncture effect of the needle of the acupuncture machine, the fluffy The fiber web is strengthened and entangled to obtain strength, thereby preparing a non-woven fabric.

Embodiment 1

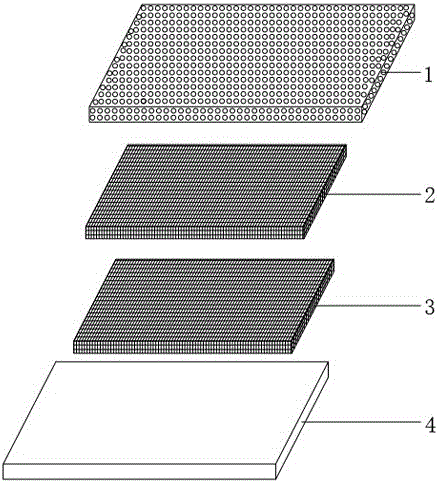

[0035] The first layer: spunlace non-woven fabric prepared by mixing chitosan fiber and cotton fiber, the non-woven fabric has a large number of meshes, the proportion of chitosan fiber is 20%, and the proportion of cotton fiber is 80%;

[0036] The second layer is a non-woven absorbent pad with a low water absorption rate, which is made of viscose fiber, and its absorption rate for pure water is 5-10 times;

[0037] The third layer: non-woven absorbent pad with high water absorption rate, made of viscose fiber and polyacrylate superabsorbent fiber, the proportion of viscose fiber is 30%, and the proportion of polyacrylate superabsorbent fiber is 70%. The absorption factor of pure water is about 52 times (W / W);

[0038] The fourth layer of isolation layer is coated paper;

[0039] The surrounding edges of the first layer and the fourth layer adopt the method of hot pressing to wrap the second layer and the third layer inside.

Embodiment 2

[0041]The first layer: spunlace non-woven fabric prepared by mixing chitosan fiber and cotton fiber, the non-woven fabric has a large number of meshes, the proportion of chitosan fiber is 20%, and the proportion of cotton fiber is 80%;

[0042] The second layer is a non-woven absorbent pad with a low water absorption rate, which is made of viscose fiber, and its absorption rate for pure water is 5-10 times (W / W);

[0043] The third layer: non-woven absorbent pad with high water absorption rate, made of viscose fiber and polyacrylate superabsorbent fiber, the proportion of viscose fiber is 40%, and the proportion of polyacrylate superabsorbent fiber is 60%. The absorption factor of pure water is about 41 times (W / W);

[0044] The fourth layer of isolation layer is coated paper;

[0045] The surrounding edges of the first layer and the fourth layer adopt the method of hot pressing to wrap the second layer and the third layer inside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com