In-situ rotary bone fracture restoration fixer

A fixer, in-situ technology, applied in the field of medical devices, can solve the problems of inconvenience of surgery, prolong the operation time, increase the probability of infection, etc., and achieve the effect of being easy to manufacture and popularize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is further described.

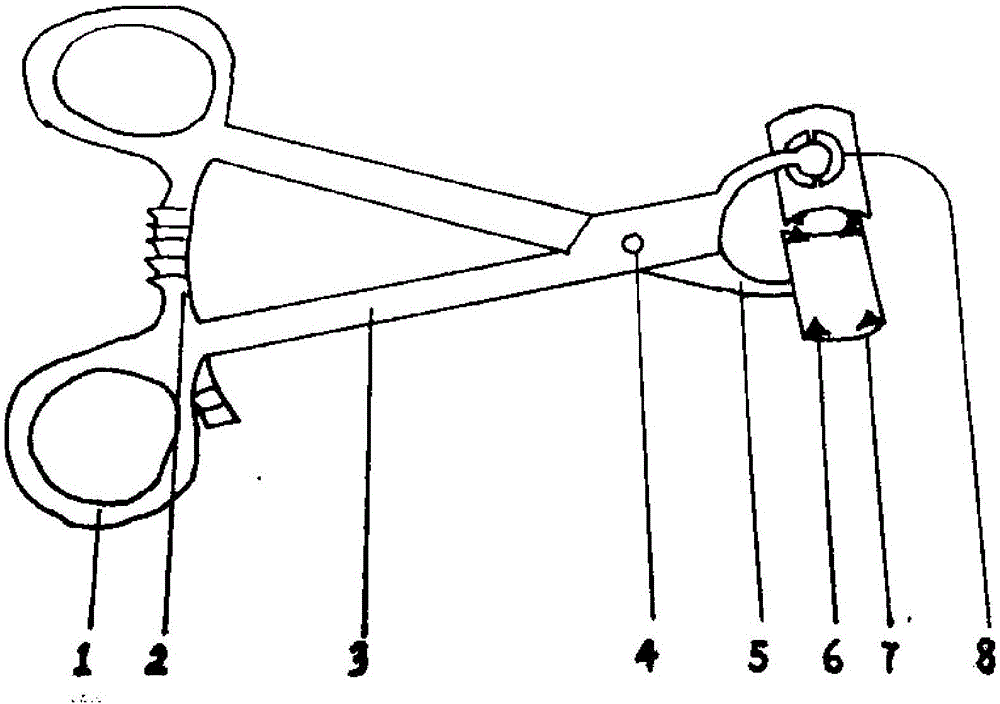

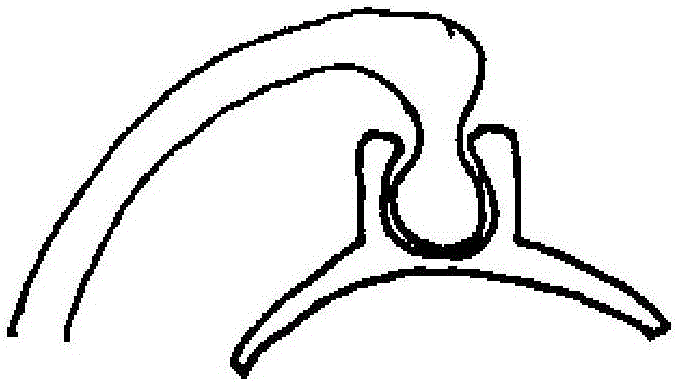

[0019] A long bone fracture reduction and fixation forceps, comprising two forceps handles 3, the two forceps handles 3 are connected by a front hinge shaft 4, the front end of the forceps handle 3 has an arc-shaped forceps head 5, and the end of the arc-shaped forceps head 5 passes through the ball The socket shaft 8 is connected with the arc-shaped elastic fixing plate 7, and the four corners of the inner surface of the fixing plate 7 each have a positioning protrusion 6, and the rear end of the pincer handle 3 has an annular pincer handle 1. The end of the pliers head is connected to the arc-shaped elastic fixing plate 7 through the ball-and-socket shaft 8, and this joint is rotatable and detachable; the fixing plate 7 is made of a material with better elasticity.

[0020] As shown in the figure, the end of the arc-shaped pliers head 5 is connected to the arc-shaped elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com