Multi-transformer series connection type power output circuit

A power output and transformer technology, applied in the field of power output circuits, to achieve the effects of avoiding damage, high efficiency, and high energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

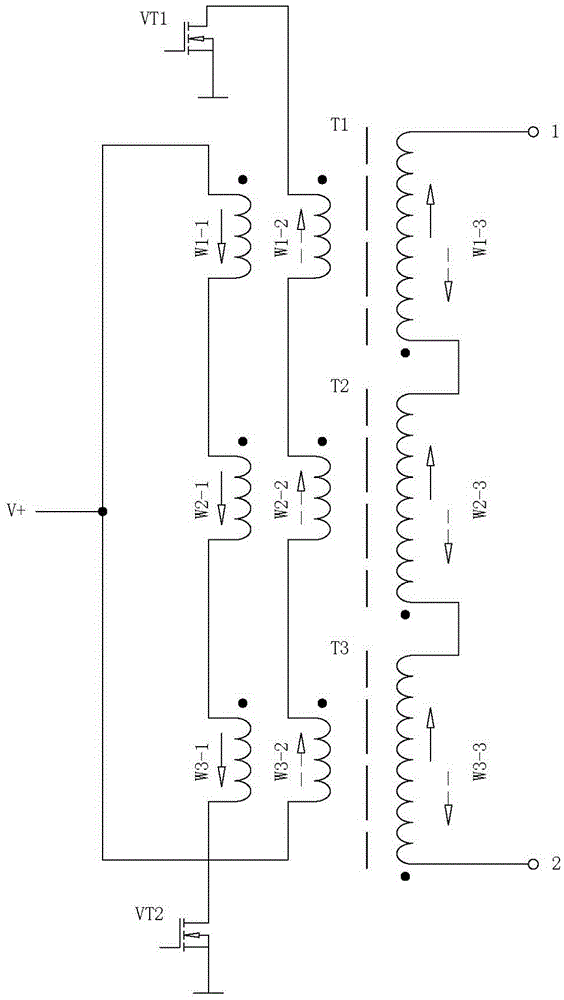

[0015] Example 1 figure 1 In the embodiment shown, the power output circuit with multiple transformers connected in series is composed of a first power switch tube (VT1), a second power switch tube (VT2) and multiple high-voltage transformer units, wherein the high-voltage transformer unit consists of a primary coil and a secondary coil. The primary high-voltage coil consists of a first primary coil and a second primary coil, the first primary coil and the second primary coil are wound in parallel with two wires, and the secondary high-voltage coil is wound on the On the frame, the primary coil and the secondary high-voltage coil are nested, the first primary coil and the second primary coil are set on the inner layer, and the secondary high-voltage coil is set on the outer layer; there are more than two high-voltage transformer units, and multiple high-voltage transformer units The first primary coils of multiple high-voltage transformer units are connected in series in forwa...

Embodiment 2

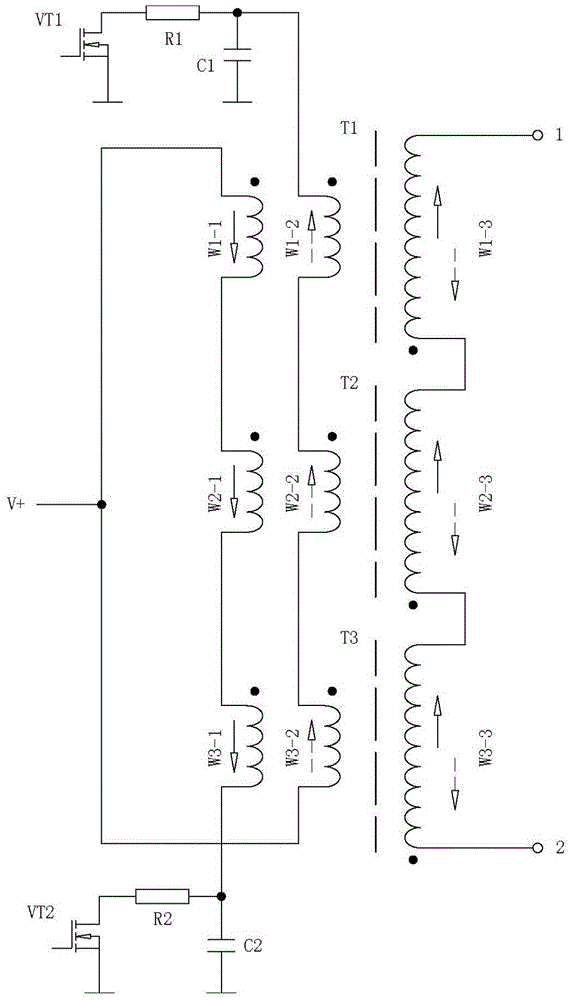

[0016] Example 2 figure 2 In the shown embodiment, on the basis of the first embodiment, there is a second absorbing capacitor (C2) between the tail end of the first primary low-voltage circuit and the ground wire, and between the head end of the second primary low-voltage circuit and the ground wire. There is a first absorption capacitor (C1) between the ground wires. The first absorption capacitor (C1) and the second absorption capacitor (C2) are used to absorb the reverse peak voltage generated by each high-voltage transformer to avoid damage to the power switching device; in the first primary There is a second current limiting resistor (R2) between the end of the low-voltage loop and the drain of the second power switch (VT2), and between the head of the second primary low-voltage loop and the drain of the first power switch (VT1). There is a first current-limiting resistor (R1) between the poles, the first current-limiting resistor (R1) and the second current-limiting re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com