Metal lithium battery

A metal lithium and battery technology, applied in the field of metal lithium batteries, can solve problems such as contact short circuit of positive pole pieces, and achieve the effect of efficient assembly and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The metal lithium battery according to the present invention will be described in detail below with reference to the drawings.

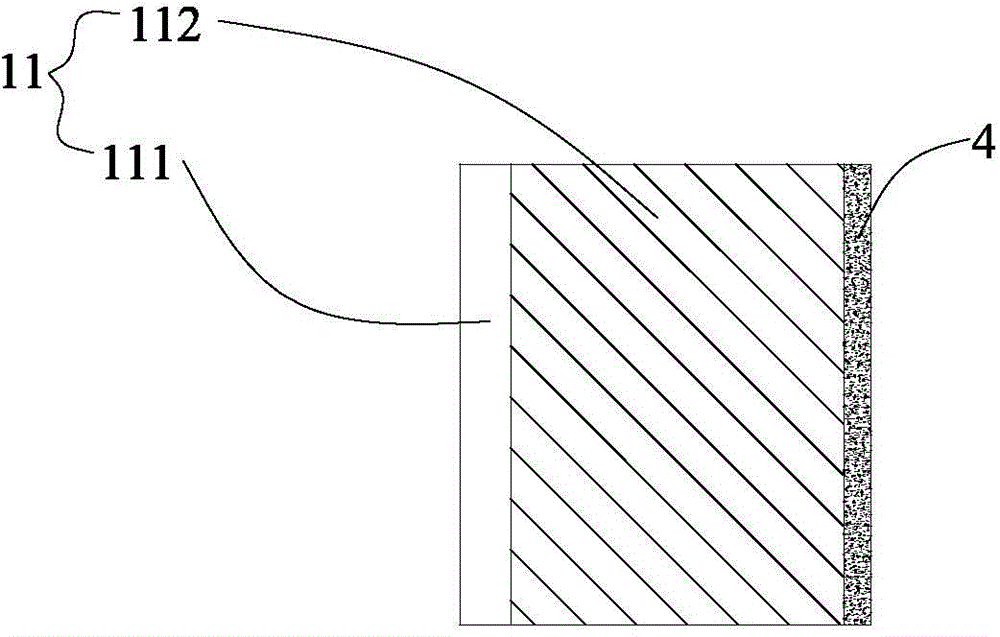

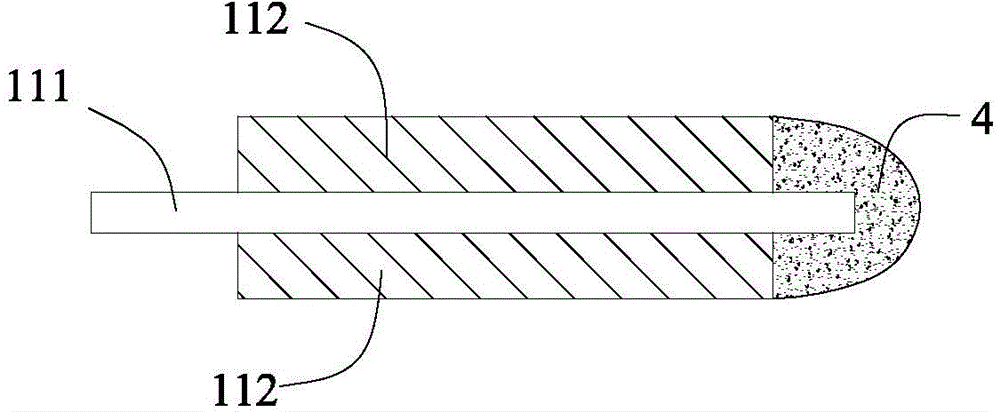

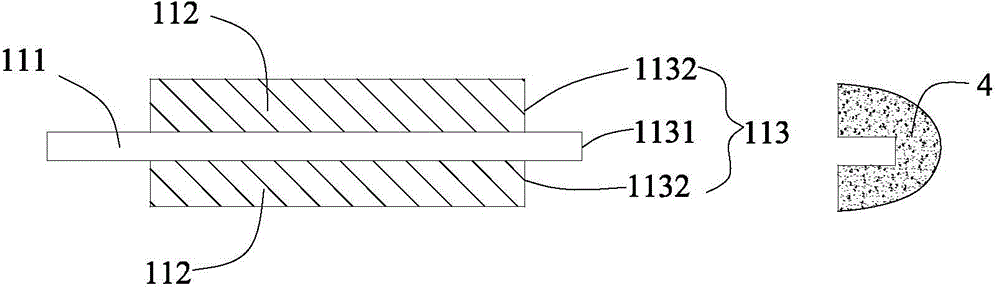

[0028] Reference Figure 1 to Figure 10 The metal lithium battery according to the present invention includes: a battery cell 1, a positive electrode tab 2, a negative electrode tab 3, and an electronic insulation coating 4. The cell 1 includes: a positive pole piece 11, including a positive electrode current collector 111 and a positive electrode active material layer 112 disposed on the surface of the positive electrode current collector 111; a negative pole piece 12, which is made of a metal lithium film; and a separator 13 located on the positive electrode. Between the sheet 11 and the negative pole piece 12; among them, the positive pole piece 11, the separator 13, the negative pole piece 12 are laminated in sequence (refer to Figure 6 to Figure 10 ), winding, or lamination and winding to form the battery core 1, and the positive pole piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com