Photovoltaic module encapsulated by high-performance weather-resistant composite material and preparation method thereof

A technology of composite materials and photovoltaic modules, applied in the field of solar photovoltaics, can solve the problems of easy degradation, yellowing, electrode corrosion, and scrapping, and achieve the effects of good anti-PID effect, high light utilization rate, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with embodiment the present invention is described in further detail.

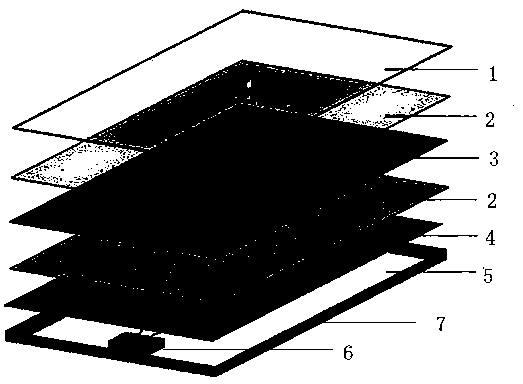

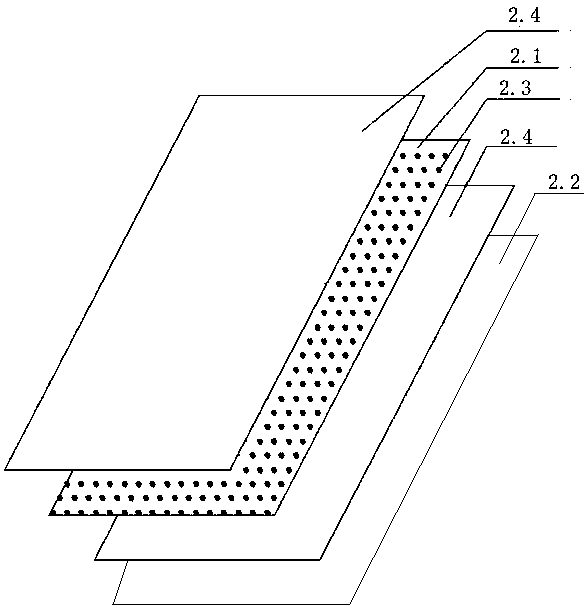

[0030] see figure 1 , the present invention relates to a high-performance weather-resistant composite material packaged photovoltaic module, which mainly includes a tempered glass 1, a battery sheet 3 and a back plate 7 arranged sequentially from top to bottom. Layer composite material adhesive film 2 replaces the conventional EVA packaging adhesive film composite crystalline silicon battery sheet 3 to form a composite layer as a whole, and uses tin-coated copper strips to connect the lead wires in series and parallel between the battery sheets, and then uses TPT polyvinyl fluoride composite film 5 Protective rubber seal, install the junction box 6 with silica gel and connect the lead wires, fix it with the back plate 7 and put it into the aluminum alloy frame 8 to form a composite material to encapsulate the photovoltaic battery module. The tempered glass is 1634×986×3.2mm, com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com