A feeding device for a diode lead correction device

A calibration device and diode technology, applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve the problem of not having a set, and achieve the effects of high calibration, uniform material feeding, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

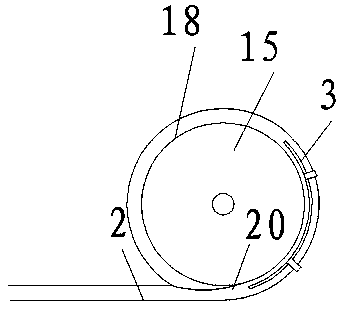

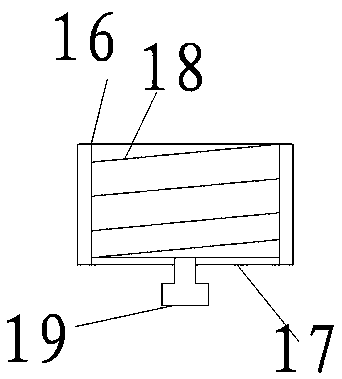

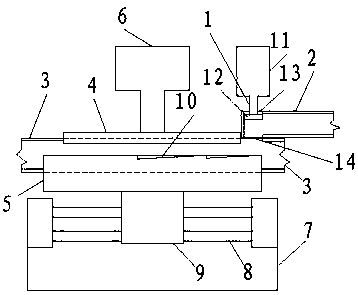

[0017] Embodiment of the present invention: a feeding device of a diode lead correction device, as shown in the accompanying drawings, includes a disc feeding device 15, and the disc feeding device 15 includes a cylindrical diode storage tank 16, which is placed in a circular The cylindrical diode storage tank 16 is provided with a spiral slide plate 18, the turntable 17 is installed in the cylindrical diode storage tank 16 and cooperates with the inner edge of the bottom of the cylindrical diode storage tank 16, and a motor 19 is set on the turntable 17 to realize the turntable Rotate, the bottom end of the helical slide plate 18 communicates with the turntable 17, and the top end of the helical slide plate 18 communicates with the diode conveyor belt 2.

[0018] Wherein, an arc-shaped clamping plate 19 is arranged at the upper layer of the spiral slide plate 18, and the height of the clamping plate 19 from the corresponding spiral slide plate 18 is greater than the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com