Metal-molybdenum-based microrelay and preparation method thereof

A technology of relays and metals, applied in the field of metal molybdenum-based micro-relays and its preparation, can solve problems such as contact failure, low reliability, and failure, and achieve the effects of solving contact resistance problems, reducing system failure, and improving impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below through specific embodiments and accompanying drawings.

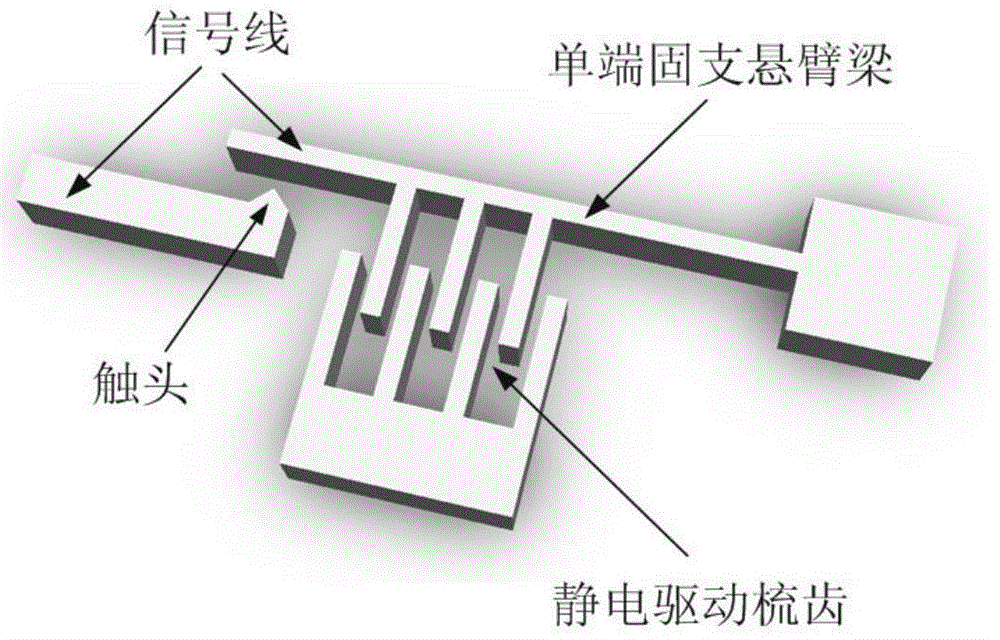

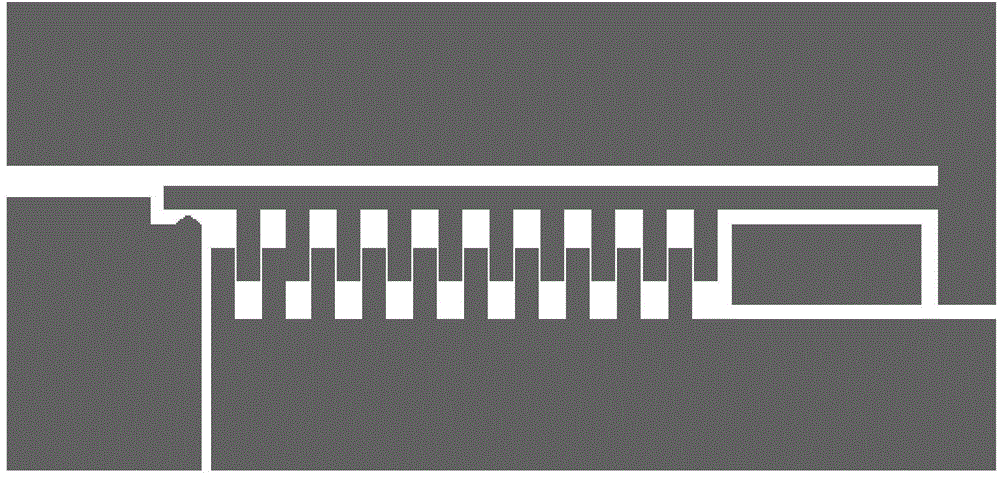

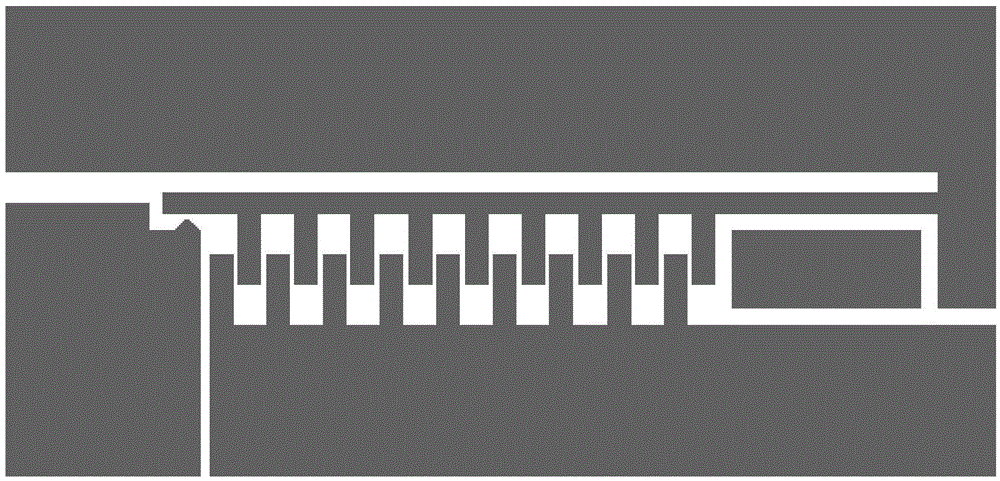

[0036] The metal-molybdenum-based micro-relay of this embodiment adopts a typical horizontal driving method, such as figure 1 shown. The cantilever beam fixed at one end is used as the elastic recovery structure, and the contact part adopts the point-surface contact scheme. There is a molybdenum sheet with a thickness of 30 microns. Considering the lateral undercutting (1:4) of the molybdenum sheet, the structure of the cantilever beam and the comb teeth is appropriately relaxed. In the designed layout, the width of the cantilever beam and the comb teeth are both 14.5 microns , the length of the cantilever beam is designed in 4 groups, which are 500 μm, 1000 μm, 1500 μm and 2000 μm respectively, and the comb tooth spacing is respectively 3 μm, 5 μm and 7 μm. In this way, a total of 12 metal molybdenum micro-relay layouts are designed, such as Figure 2 to F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com