Anti-wear and compression-resistant armored control cable

A control cable and armoring technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve problems such as overheating of cables and sheath damage, and achieve extended service life, good torsion resistance, and prevent crushing or breaking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

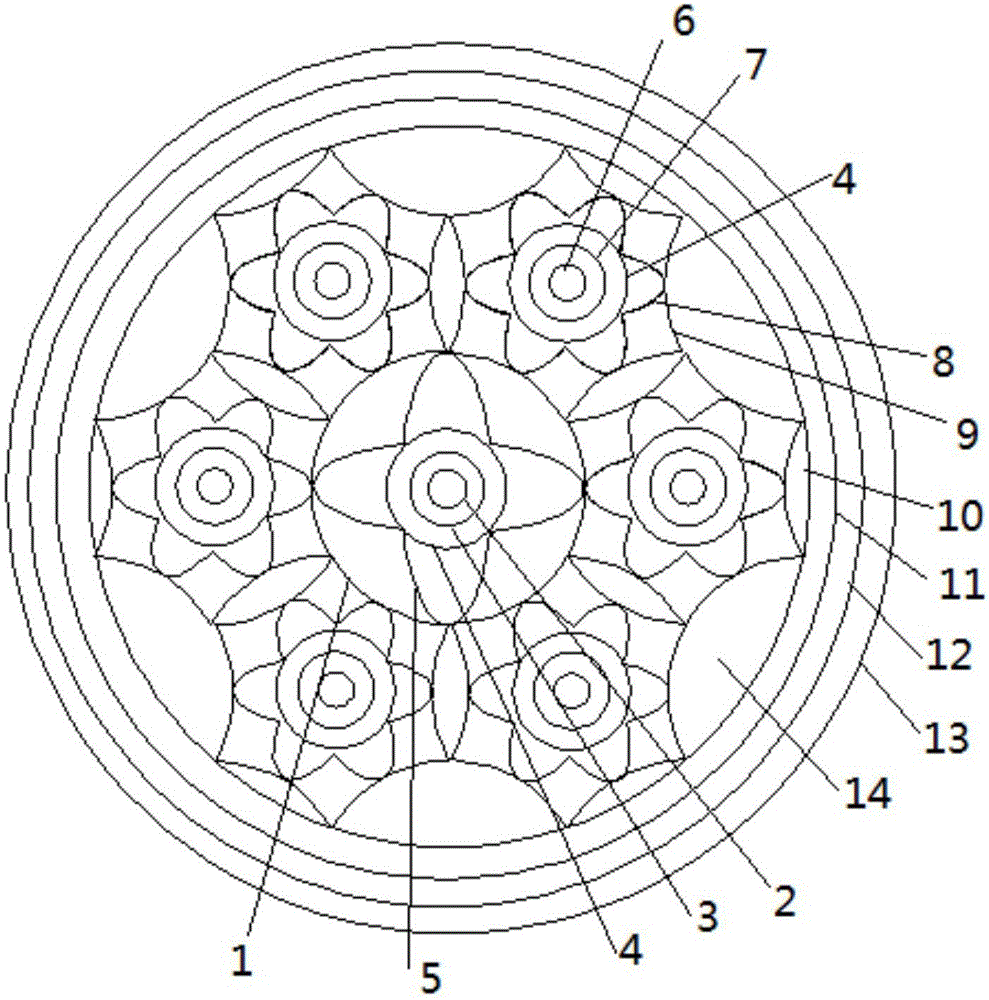

[0014] Such as figure 1 As shown, a wear-resistant and pressure-resistant armored control cable includes a cable core, a circular insulating tube 1 is arranged in the center of the cable core, and a main wire core is arranged inside the circular insulating tube 1. The main wire The core includes a main conductor 2 and a vinyl fluorosilicone rubber insulating layer 3 coated on the outside of the main conductor 2, a semi-conductive shielding layer 4 and a petal-shaped insulating tube 5. The petal-shaped insulating tube 5 is formed by four outer Convex arc-shaped plates are spliced end to end, and there are six control wire cores evenly distributed on the outside of the circular insulating tube 1. The control wire cores include the control conductor 6 and the poly Olefin irradiated insulating layer 7, semi-conductive shielding layer 4, petal-shaped heat-resistant tube 8 and hexagonal insulating tube 9, the petal-shaped heat-resistant tube 8 is formed by splicing end to end of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com