Laser leveling system control method based on fuzzy control

A fuzzy control, laser leveling technology, applied in two-dimensional position/channel control and other directions, can solve problems such as loss of tractor life, hidden driving safety hazards, tractor engine overload, etc., and achieve the effect of high-efficiency lifting height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

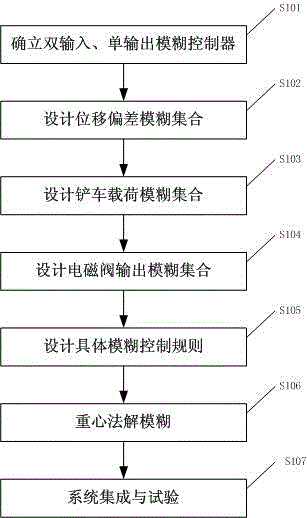

[0056] figure 1 It is a flowchart of a control method for a laser leveling system based on fuzzy control in the present invention; the method includes the following steps:

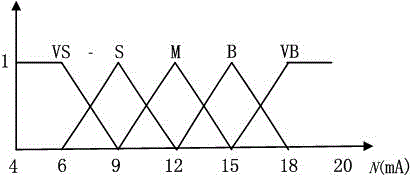

[0057] S101, using a dual-input, single-output fuzzy controller, using the displacement deviation and the load of the forklift as the input of the fuzzy controller, and the power-on time of the solenoid valve as the output control value, so as to control the lifting of the forklift more precisely and efficiently high. The laser leveling system uses seven laser receivers;

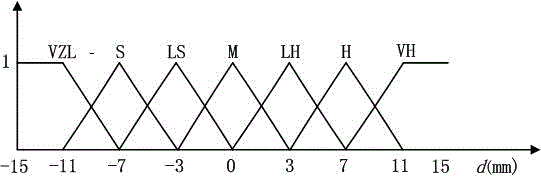

[0058] S102, judging the topography at the position where the laser signal hits the laser receiver in real time, obtaining the displacement deviation, and designing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com