A device for fixing wind tunnel wedges

A technology of wind tunnel and metal cap, which is applied in the field of base fixing devices, can solve the problems of being easily blown down by the wind and test wind speed, etc., and achieve the effects of strong anti-friction ability, wide wind speed range, and improved compressive stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the drawings and technical solutions.

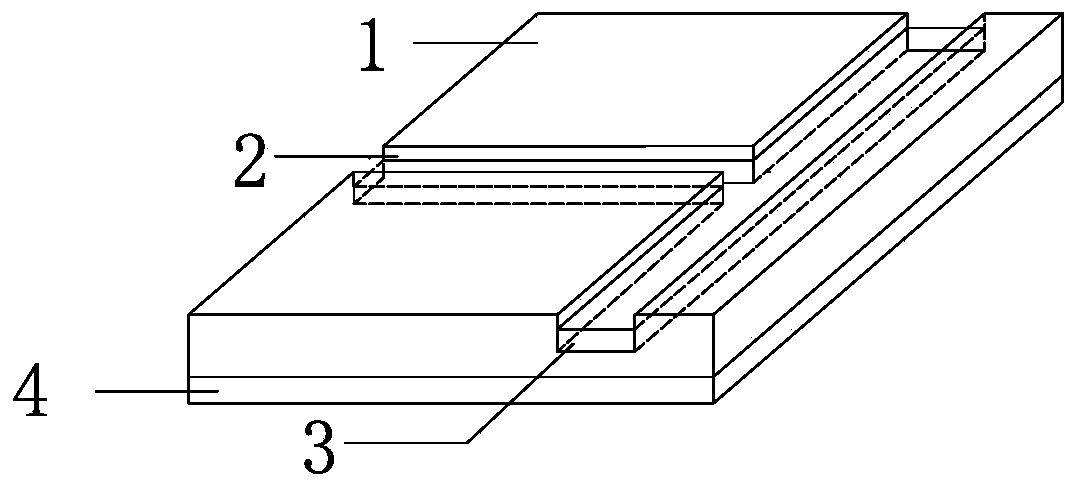

[0016] Such as figure 1 As shown, a rubber cushion layer 3 is embedded in the groove 2 of the detachable base 1, and the rubber cushion layer 4 is pasted on the bottom surface of the base.

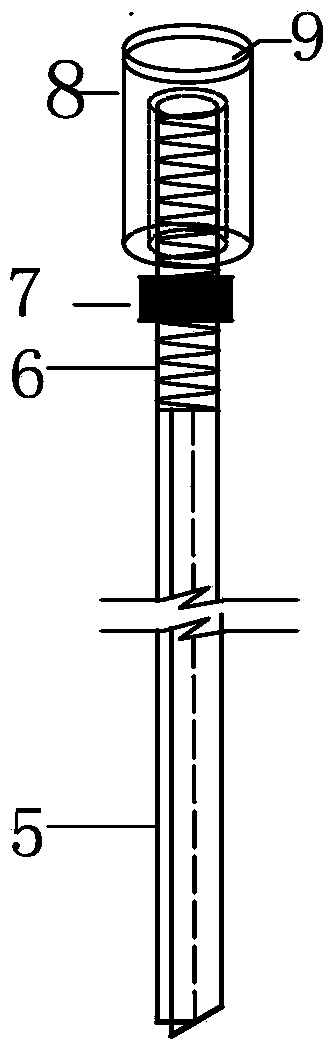

[0017] Such as figure 2 As shown, a screw rod 6 (generally 2-3cm in diameter, 8-10cm in length) is welded on the top of the vertical shaft 5, a nut 7 is placed on the screw rod, and a metal cap 8 is fastened on the top of the screw rod 6, and the metal A rubber cushion 9 is pasted on the top of the cap 8.

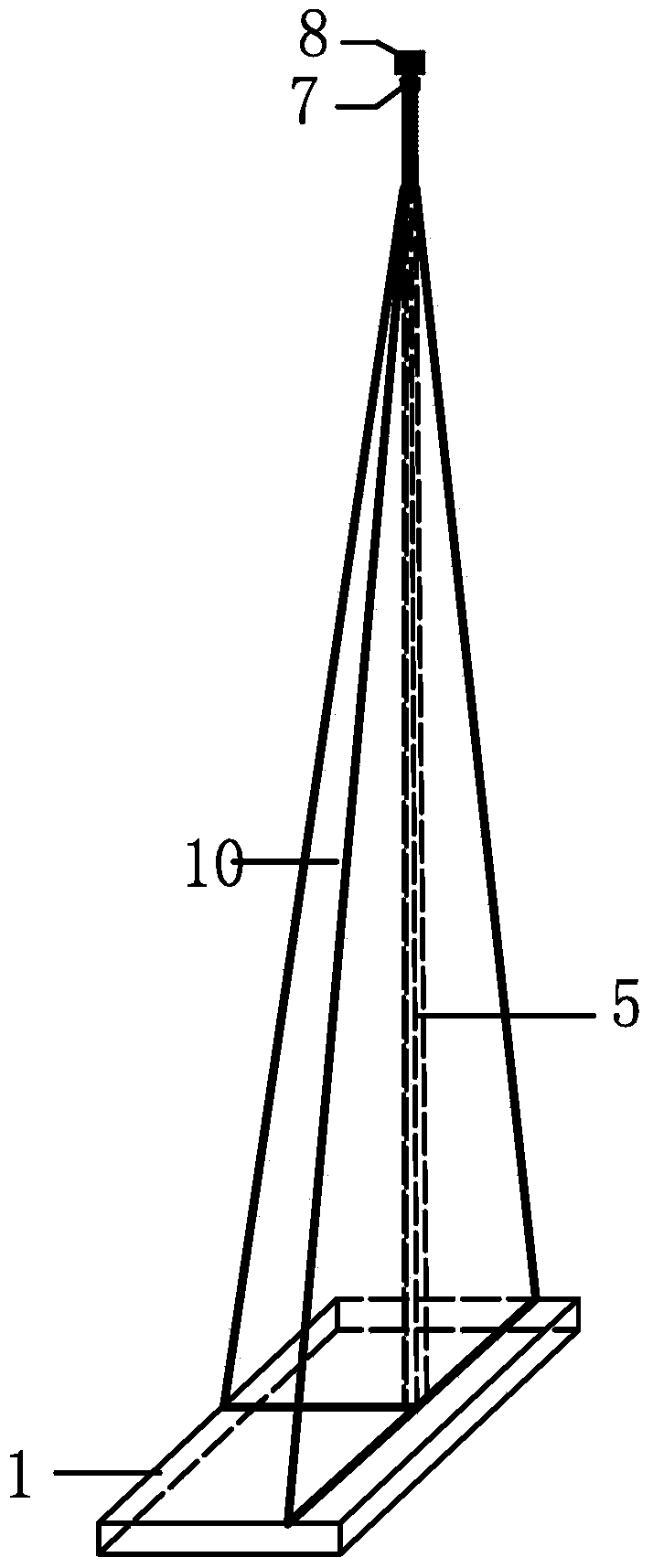

[0018] Such as image 3 As shown, the wedge main body 10, the wedge shaft 5 and the screw rod 6 are consolidated into a whole, the detachable base (1-4) is placed flat on the designated position, and the wedge is vertically inserted into the groove 2. Make it press on the cushion layer 3. By rotating the nut 7 on the screw rod 6, the metal cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com