Comprehensive oil and gas pipeline leakage monitoring system

A comprehensive monitoring, oil and gas pipeline technology, applied in the pipeline system, gas/liquid distribution and storage, instruments, etc., can solve the problems of poor security of leakage monitoring technology, inaccurate positioning accuracy, oil and gas pipeline leakage, etc., and achieve short system response time , high positioning accuracy and stable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

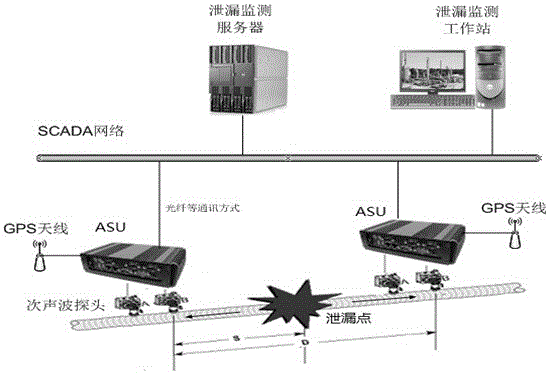

[0017] Such as figure 1 as shown,

[0018] A comprehensive monitoring system for oil and gas pipeline leakage, which is mainly composed of infrasonic sensors, acoustic monitoring terminals, clock servers and leakage monitoring servers. Two infrasonic sensors are respectively installed at the upstream and downstream detection points of the pipeline to be monitored. When there is a leak, an infrasonic signal will be generated. By comparing this signal with the normal background noise, it can be judged whether the leak has occurred. The infrasonic sensor will preprocess and amplify the collected infrasonic signal due to the pipeline leakage, and convert it into a multi-channel in the digital domain. The sound wave signal is transmitted to the signal acquisition and analysis system; the signal acquisition and analysis system determines the location of the leak according to the time difference between the arrival of the infrasonic signal at the upstream detection point and the down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com