A semi-active air suspension device for high-speed trains with adjustable stiffness and damping

A technology for high-speed trains and air suspension, applied in the direction of vibration suppression adjustment, non-rotational vibration suppression, springs, etc., can solve the problems that the vertical damping cannot be adjusted adaptively, and the best stiffness response cannot be achieved, and the control process is precise and reliable. The process is reversible and the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the drawings.

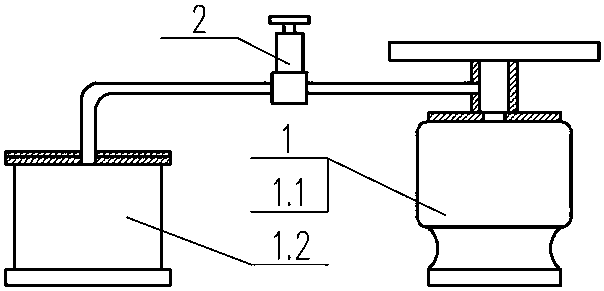

[0027] Such as figure 1 As shown, the semi-active air suspension device for a high-speed train with adjustable stiffness and damping includes an air spring mechanism 1 and a control mechanism 2.

[0028] The air spring mechanism 1 includes a main air chamber 1.1 and an additional air chamber 1.2.

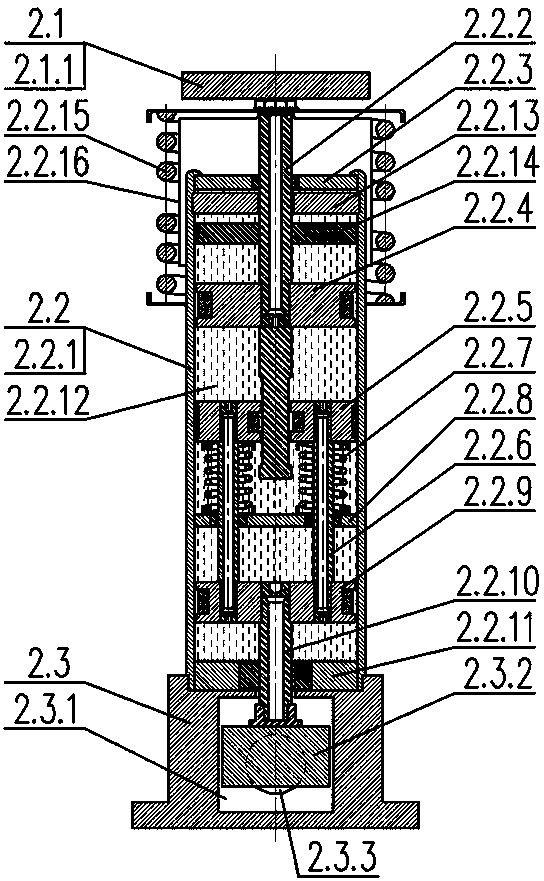

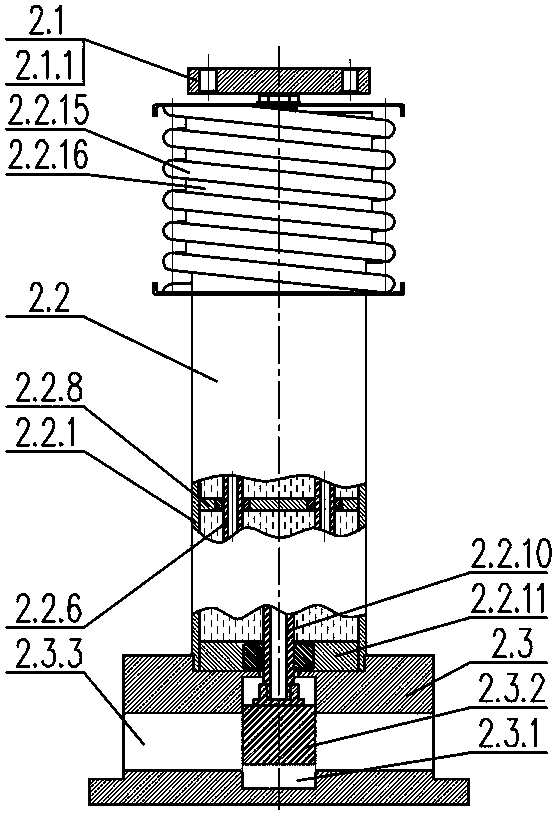

[0029] Such as figure 2 , image 3 As shown, the control mechanism 2 includes a coupling assembly 2.1, a cylinder assembly 2.2, and a fixed base 2.3. The cylinder assembly 2.2 is vertically fixed and installed on the fixed base 2.3.

[0030] The cylinder assembly 2.2 is a cylindrical structure, including the cylinder 2.2.1, the cylinder 2.2.1 is filled with magnetorheological fluid 2.2.12, and the cylinder 2.2.1 is provided with a piston rod I 2.2.2 from top to bottom. , Cylinder head 2.2.3, damping piston Ⅰ 2.2.4, damping piston Ⅱ 2.2.5, piston rod Ⅱ 2.2.6, support spring 2.2.7, diaphragm 2.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com