Rock-anchored beam construction trolley and construction method thereof

A technology of construction trolley and rock anchor beam, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc. It can solve the problems of long construction period, high cost and complicated construction process, so as to improve stability and facilitate installation and disassembly , the effect of streamlining the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

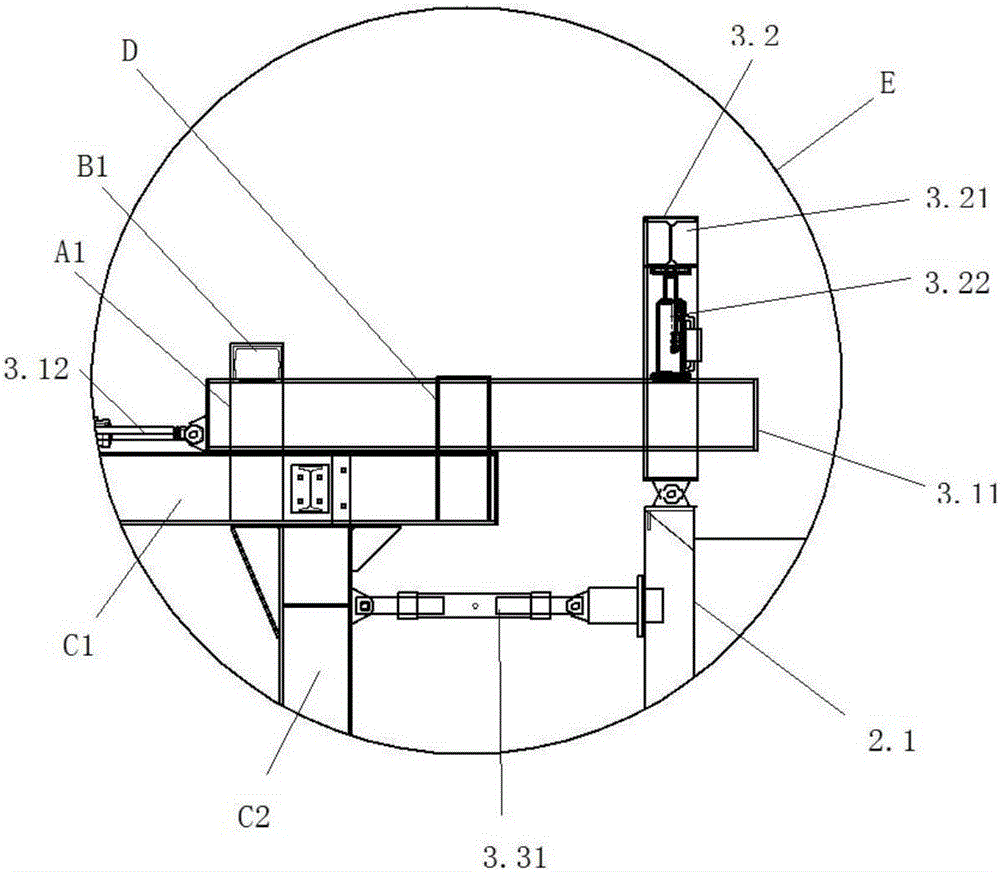

[0046] A rock anchor beam construction trolley, see Figure 1-Figure 5 , including a skeleton part 1, a formwork part 2 which is movably arranged on the skeleton part 1 through a connecting part 3, and a plurality of groups arranged at the bottom of the skeleton part 1 and used to move the entire trolley (so that the trolley is on the ground 6 Walking mechanism 4 that is convenient for walking.

[0047] The skeleton part 1 (see for details figure 1 and figure 2 ) includes a lower frame 1.1 and an upper frame 1.2 arranged on the lower frame 1.1, the lower frame 1.1 and the upper frame 1.2 are connected by a plurality of beams C1, a plurality of columns C2 and a plurality of longitudinal beams C3 The frame steel structure formed (the specific structure of the upper skeleton and the lower skeleton can refer to the prior art, and there are many ways to build it); the template part 2.1 is connected with the upper skeleton 1.2 through the connecting part 3; the lower skeleton 1.1...

Embodiment 2

[0062] A rock anchor beam construction trolley, which is different from Embodiment 1 in that it also includes an electro-hydraulic control part, and the traversing cylinder 3.12, jacking cylinder 3.22, side cylinder 3.31 and traveling mechanism 4 are all connected to the electric Liquid control part connection.

[0063] The design of the electro-hydraulic control part facilitates the automatic control of the traversing oil cylinder, jacking oil cylinder, lateral oil cylinder and traveling mechanism (the design of the hydraulic system and circuit system can be combined in the electro-hydraulic control part, for details, please refer to the platform in the prior art The hydraulic and electro-hydraulic control part of the vehicle), greatly improving work efficiency and further shortening the construction period.

[0064] Lining rock anchor beams of the same length, using the rock anchor beam construction trolley of this embodiment to carry out construction is compared with the ap...

Embodiment 3

[0066] A rock anchor beam construction trolley differs from Embodiment 1 in that: the formwork part includes a set of formwork parts; the connecting part includes a set of connectors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com