An online intelligent control nozzle device for water injection wells

A water injection well, intelligent technology, applied in wellbore/well components, production fluid, earthwork drilling and other directions, can solve the problems of inability to adjust the nozzle, poor real-time measurement and adjustment, low water distribution accuracy, etc., to reduce friction loss, ensure The effect of working reliability and improving torque transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

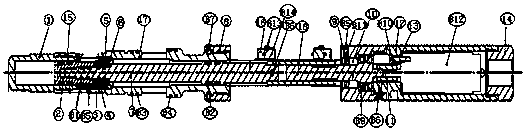

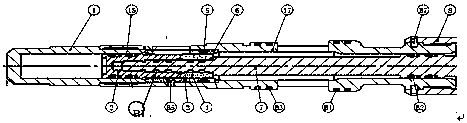

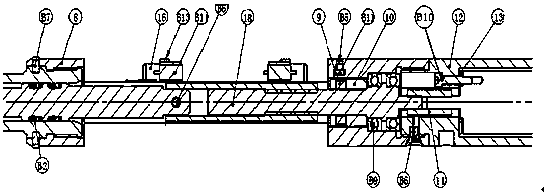

[0022] according to figure 1 As shown in FIG. 1 , an online intelligent control nozzle device for water injection wells includes a drive mechanism, a transmission mechanism, and a balance valve mechanism connected sequentially from bottom to top.

[0023] The driving mechanism mainly includes: magnetic steel 9, spacer sleeve 10, coupling 11, motor base 12, shock absorbing washer 13, compression ring 14, thrust bearing B9, Hall element B11, motor reducer B12. The Hall element B11 is fixed on the trapezoidal screw 18 through the slotted flat-end set screw B5, the magnetic steel 9 is placed in the spacer 10, and the motor reducer B12 is fixed on the motor base 12 through the hex socket head cap screw B10. And a shock a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com