Method for improving carbon dioxide recovery rate and purity by solution recycling and regeneration

A technology of carbon dioxide and solution circulation, applied in the direction of liquid washing gas purification, removal of gas pollutants, air quality improvement, etc., can solve problems such as difficulty in obtaining purity, and achieve the effect of increasing industrial output value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

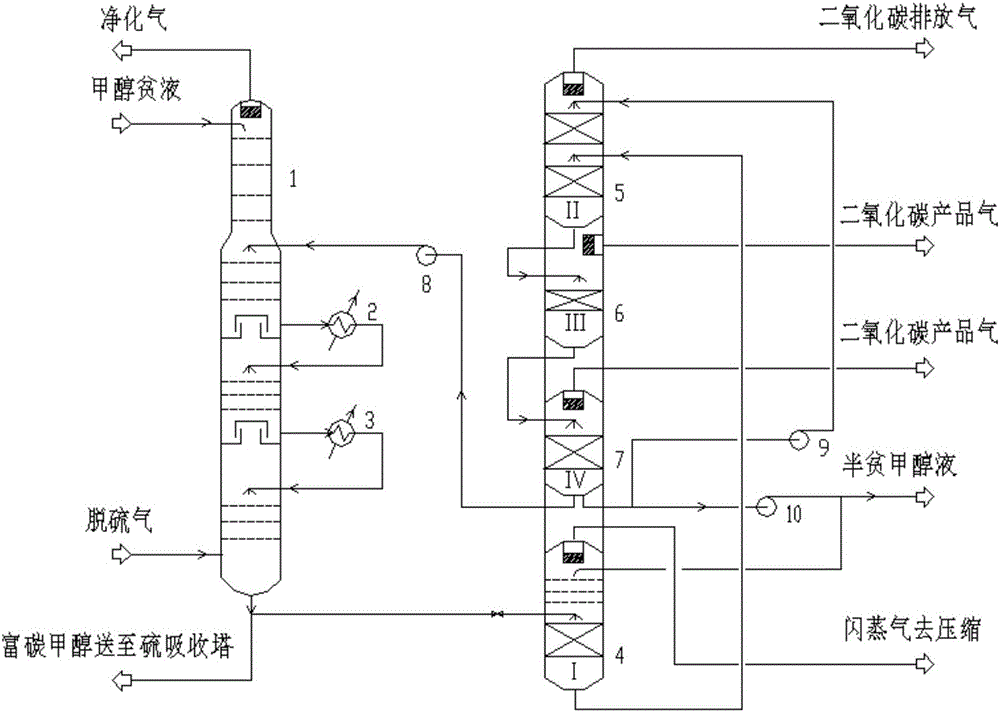

[0037] A method for improving the recovery rate and purity of carbon dioxide through solution recycling and regeneration in this embodiment comprises the following steps:

[0038] (1)CO 2 absorb

[0039] First, the crude gas with a pressure of 3.0Mpa is passed through a hydrogen sulfide absorption tower to remove H 2 Sulfur element in S and COS, desulfurized crude gas flow rate from hydrogen sulfide absorption tower is 280000Nm 3 / h, temperature: -30°C, pressure: 30bar, the specific gas composition of desulfurization gas is:

[0040] composition

H 2

N 2

CO

CH 4

CO 2

∑

V%

43.6

0.72

17.7

9.9

28.08

100.0

[0041] Then enter the CO 2 Absorption tower 1, methanol lean liquid from CO 2 The top of the absorption tower 1 is injected, and the CO 2 The desulfurized gas entering the bottom of the absorption tower 1 is contacted in countercurrent, in the CO 2 Carbon dioxide removal is carried out in the absorption tow...

Embodiment 2

[0064] A method for improving the recovery rate and purity of carbon dioxide through solution recycling and regeneration in this embodiment comprises the following steps:

[0065] (1)CO 2 absorb

[0066] First, the crude gas is passed through a hydrogen sulfide absorption tower to remove H 2 Sulfur element in S and COS, desulfurized crude gas flow rate from hydrogen sulfide absorption tower is 250000Nm 3 / h, temperature: -25°C, pressure: 45bar, the specific gas composition of desulfurized gas is:

[0067] composition

H 2

N 2

CO

CH 4

CO 2

∑

V%

40.6

0.79

20.0

8.98

29.63

100.0

[0068] Then enter the CO 2 Absorption tower 1, methanol lean liquid from CO 2 The top of the absorption tower 1 is injected, and the CO 2 The desulfurized gas entering the bottom of the absorption tower 1 is contacted in countercurrent, in the CO 2 Carbon dioxide removal is carried out in the absorption tower 1, from CO 2 The solutio...

Embodiment 3

[0091] A method for improving the recovery rate and purity of carbon dioxide through solution recycling and regeneration in this embodiment comprises the following steps:

[0092] (1)CO 2 absorb

[0093] First, the crude gas is passed through a hydrogen sulfide absorption tower to remove H 2 Sulfur elements in S and COS, the desulfurized raw gas flow rate from the hydrogen sulfide absorption tower is 200,000Nm 3 / h, temperature: -12°C, pressure: 60bar, the specific gas composition of desulfurized gas is:

[0094] composition

H 2

N 2

CO

CH 4

CO 2

∑

V%

41.6

0.79

19.0

12.61

26.0

100.0

[0095] Then enter the CO 2 Absorption tower 1, methanol lean liquid from CO 2 The top of the absorption tower 1 is injected, and the CO 2 The desulfurized gas entering the bottom of the absorption tower 1 is contacted in countercurrent, in the CO 2 Carbon dioxide removal is carried out in the absorption tower 1, from CO 2 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com