Horizontal microwave cracking furnace for solid organic matter

A solid organic matter, cracking furnace technology, applied in coke ovens, special forms of dry distillation, petroleum industry and other directions, can solve the problems of low resource recycling rate, poor equipment operation effect, low technology maturity, etc., to achieve fast heating speed, easy to use. Control, fast cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings.

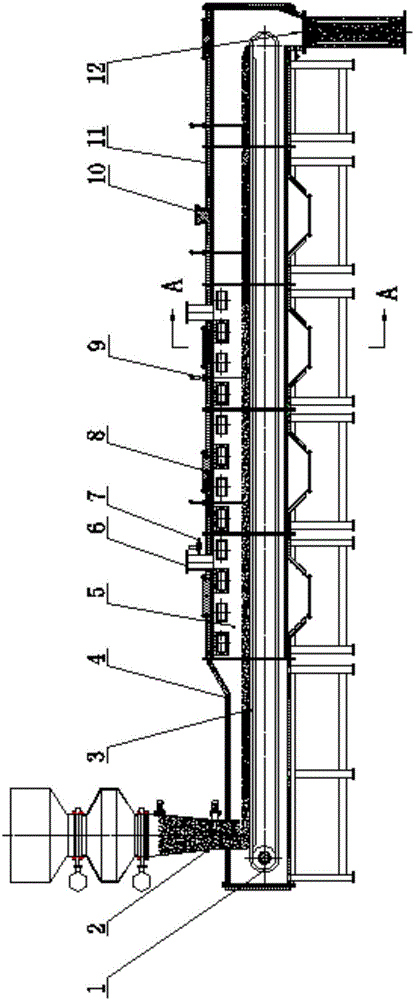

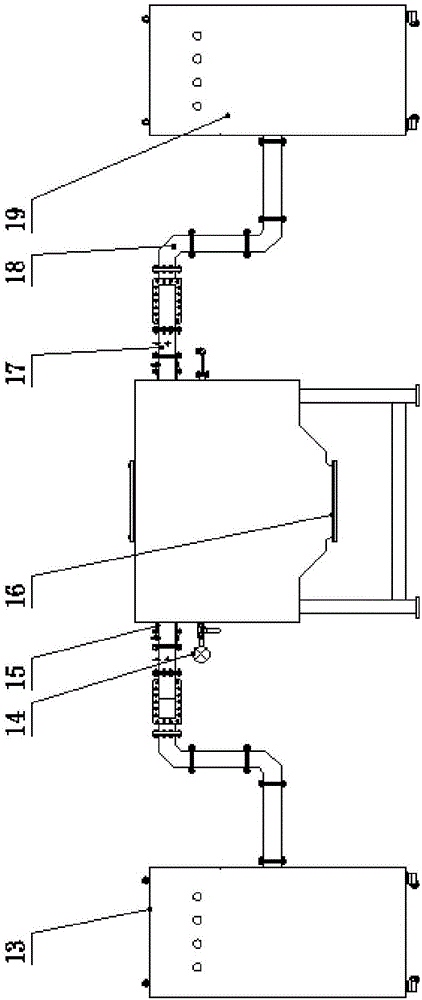

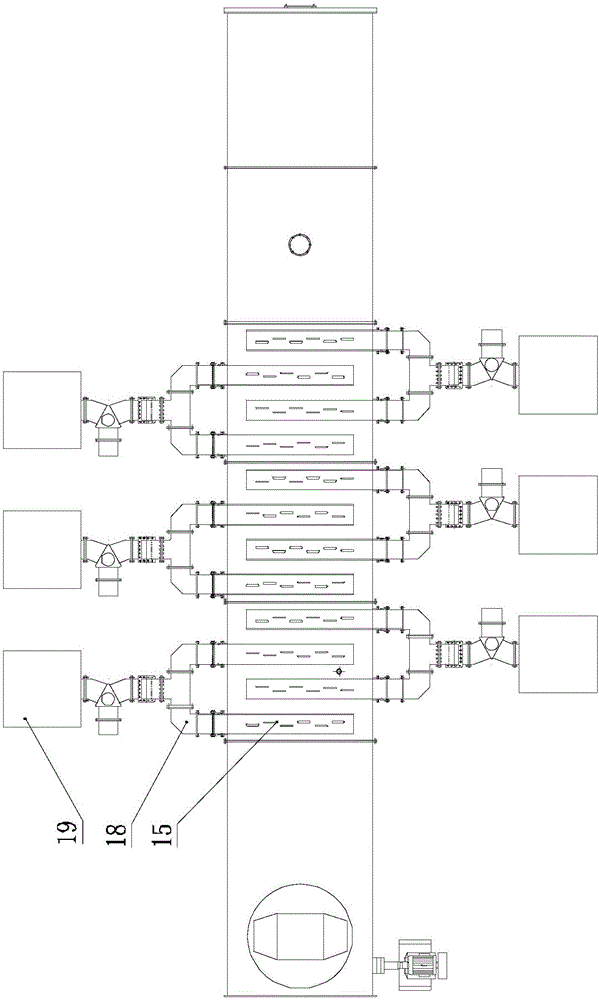

[0027] See figure 1 , figure 2 , image 3 with Figure 4 , Solid organic matter horizontal microwave cracking furnace includes frame 1, frame 1 is welded with carbon steel profile, and the surface is treated with anticorrosion. A furnace cavity composed of a feeding device 2, a feeding microwave suppressor 4, a microwave heating furnace 5, a discharging microwave suppressor 11, and a discharging device 12 is installed on the frame 1, and the joints of each section are sealed to prevent the furnace The gas generated in the cavity leaks; a conveying device 3 is installed in the furnace cavity, and the conveying device 3 passes through the microwave heating furnace 5 and has one end connected to the feeding device 2 and the other end to the discharging device 12 Butt joint, the central axis of the whole furnace is placed horizontally, which is convenient for installation and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com