A self-suspending proppant for clear water fracturing system

A clear water fracturing and self-suspension technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of high cost, large amount of organic materials used, environmental pollution, etc., to reduce the damage to the formation environment, improve Effect of oil and gas production and reduction of fracturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

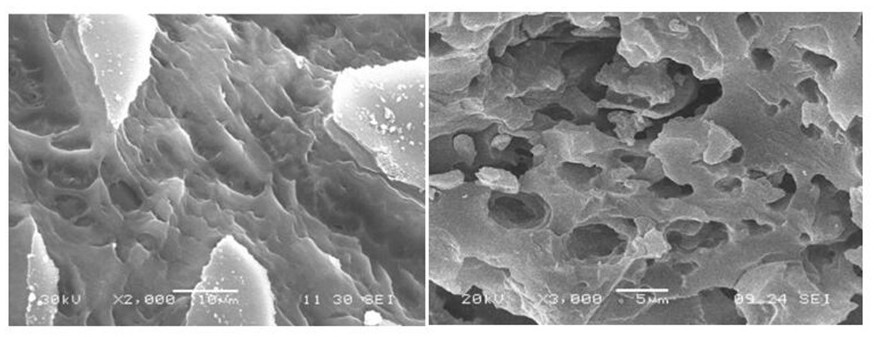

Image

Examples

Embodiment 1

[0051] The self-suspending proppant applied to the clear water fracturing system provided in this example is prepared by the following steps:

[0052] (1) Prepare gelatinized starch, specifically, add deionized water to cornstarch to prepare a starch solution with a mass fraction of 10%, add 1g sodium hydroxide to 300mL starch solution, place in a constant temperature water bath at 80°C for 2 hours, and cool to room temperature After that, it is gelatinized starch;

[0053] In this step, starch:sodium hydroxide=30:1 in parts by mass.

[0054] (2) Preparation of hydrogel materials, the specific process is:

[0055] First, the reaction device is installed, specifically, a stirrer, a reflux condenser, a thermometer, a nitrogen inlet and outlet pipe and a dropping funnel are installed on a 500mL four-necked flask;

[0056] Secondly, under the condition of constant temperature water bath at 65°C, add 4g of emulsifier (span-80) and 150mL of cyclohexane to the four-neck flask succe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com