Automatic ingot loading and unloading system

A technology for automatic loading and unloading of spindles, which is applied in the directions of transportation and packaging, processing of thin materials, and transportation of filamentous materials. It can solve the problems of high labor intensity and low work efficiency, and achieve the effect of improving work efficiency and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

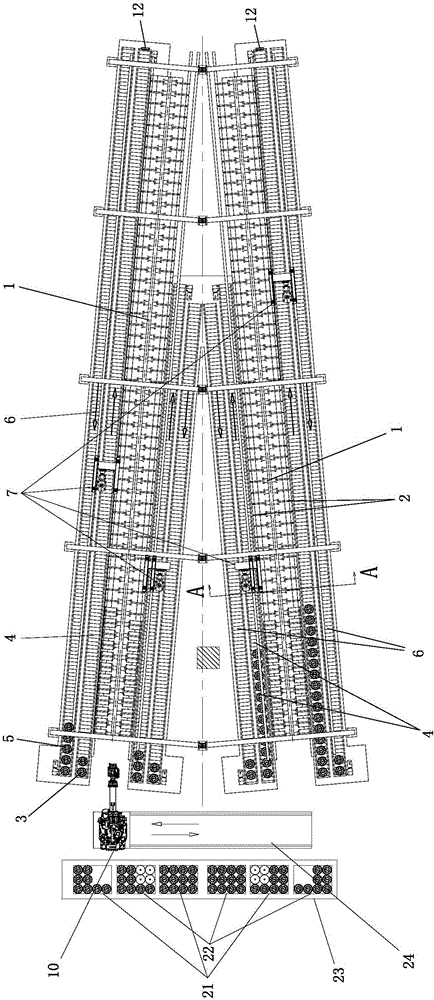

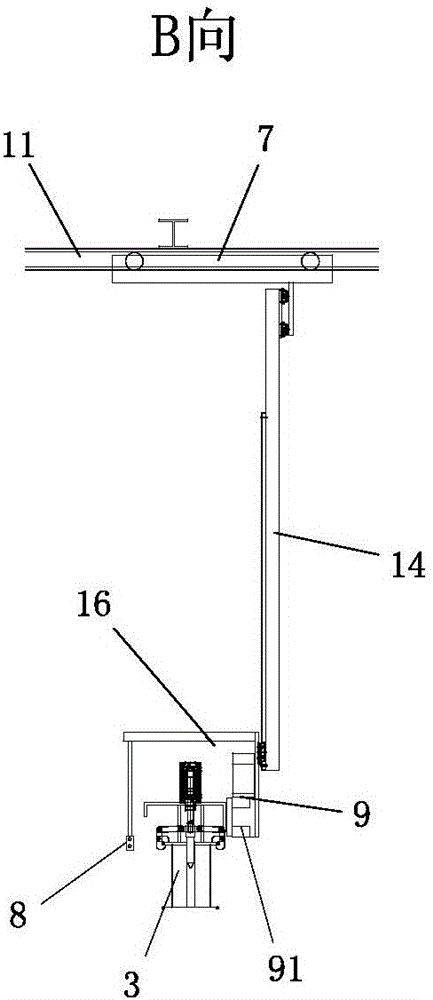

[0024] Below in conjunction with accompanying drawing, concrete structure among the present invention is described:

[0025] An automatic spindle loading and unloading system, such as Figure 1 to Figure 3 As shown, it includes a spindle frame 1, the two sides of the spindle frame 1 are fixed with spindle installation shafts 2; The spindle conveying device 6 and the traveling trolley device 7 that can move along the length direction of the spindle frame 1, the traveling trolley device 7 is provided with a device for removing the empty spindle 5 from the spindle installation shaft 2 and placing it on the empty spindle The spindle unloading device 8 on the conveying device 6 and the spindle loading device 9 for installing the full spindle 3 on the full spindle conveying device 4 on the spindle installation shaft 2, each of the above-mentioned devices (including the walking trolley device) 7. The actions of the empty spindle conveying device 6, the full spindle conveying device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com