Assembled crane for container vessel and assembling manner of assembled crane

A container ship, assembled technology, used in ship accessories, transportation and packaging, cargo handling equipment, etc., to achieve the effect of righting the ship, reducing the draft, and balancing the weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

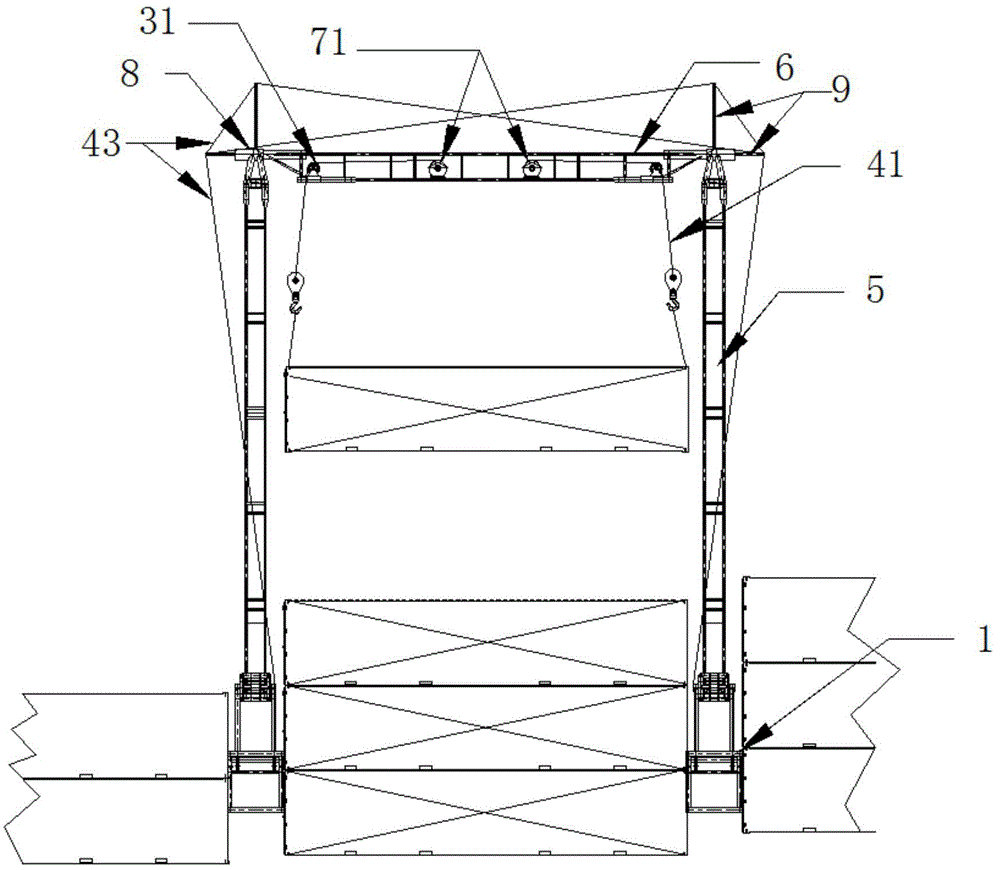

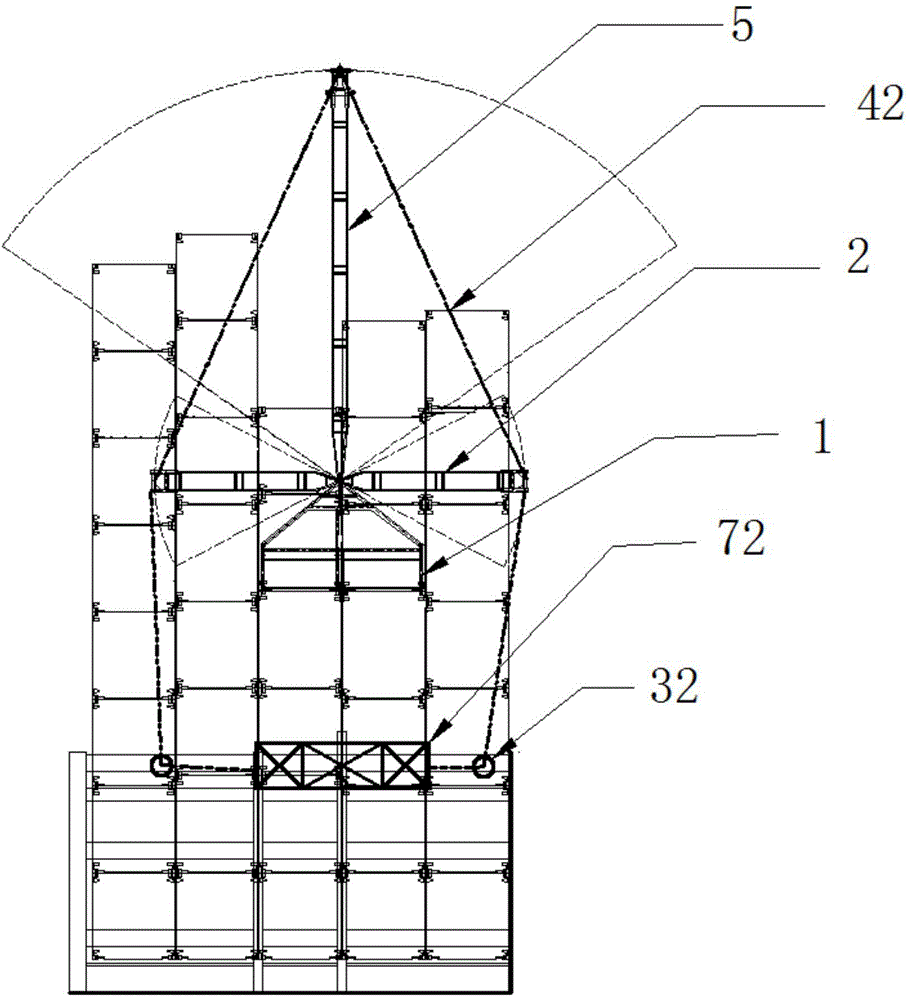

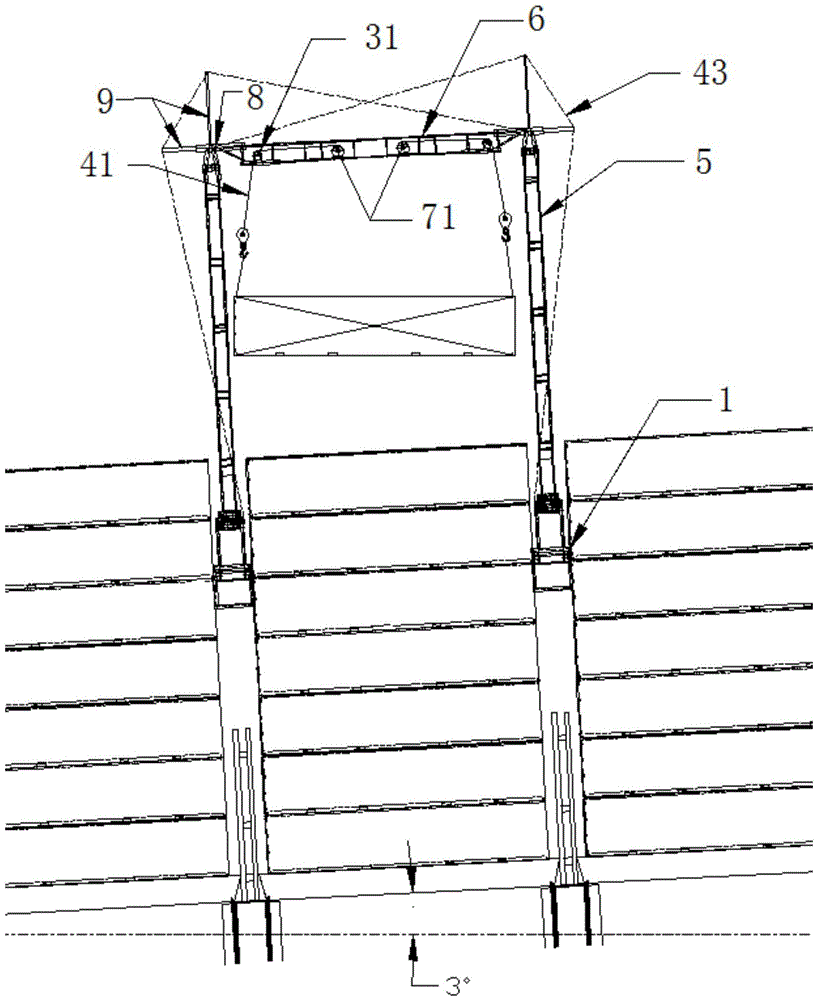

[0048] The specific implementation manner of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0049] Such as Figure 1-8 As shown, the container ship assembled crane is disassembled into several structural components, placed in a standard container, and carried on board. In an emergency, on the deck of a container ship, with the aid of an auxiliary crane, rapid assembly can be achieved. Based on the corner fitting holes of the containers at both ends, the crane base 1 is inserted into the corner fitting holes as the hoisting foundation of the crane. A hoisting container hoisting winch 71 is installed on the top beam 6 to realize the hoisting function. The assembled crane for the container ship is directly connected with the container ship. After the inspection and testing are completed, the container is urgently unloaded onto the barge to reduce the eccentric weight of the container ship, and the container ship floats aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com