Grinding and Polishing Technology of Revolving Shaped Stone Railings

A rotary and stone technology, applied in the direction of grinding workpiece support, grinding/polishing equipment, grinding/polishing safety device, etc., can solve the problems of large abrasive loss and low efficiency, achieve small loss, save abrasive, and ensure The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

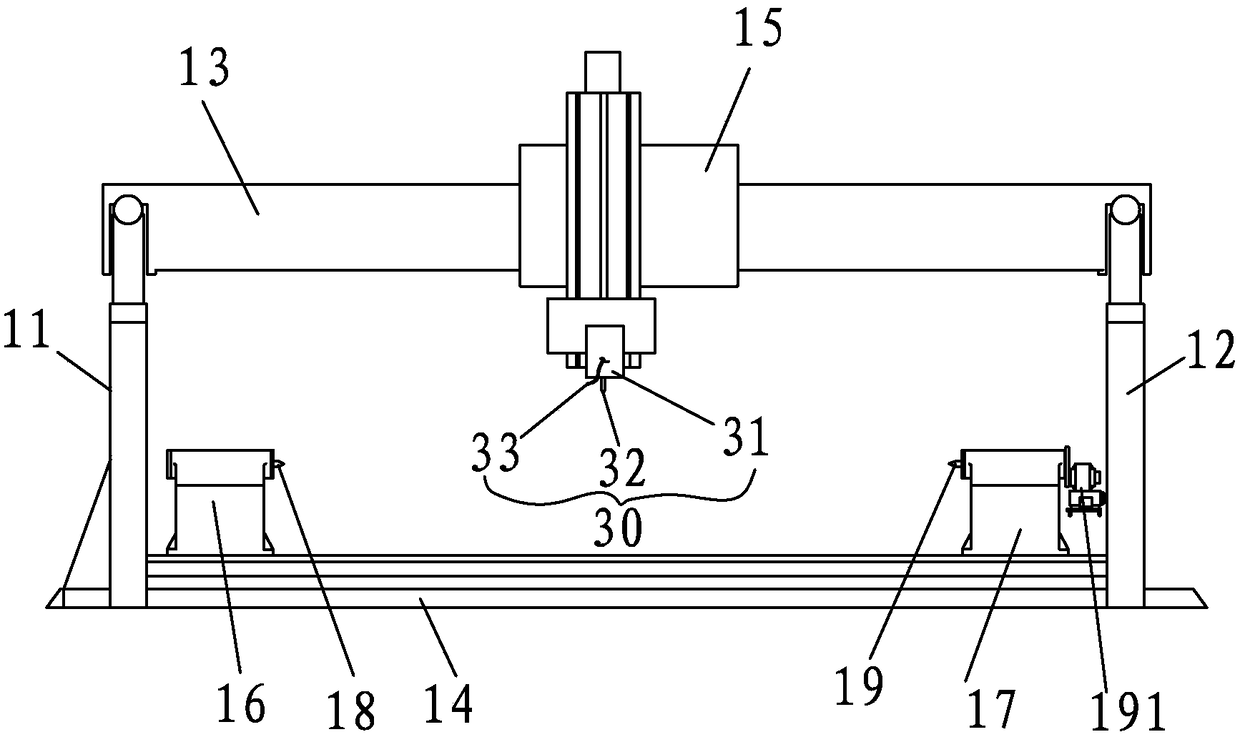

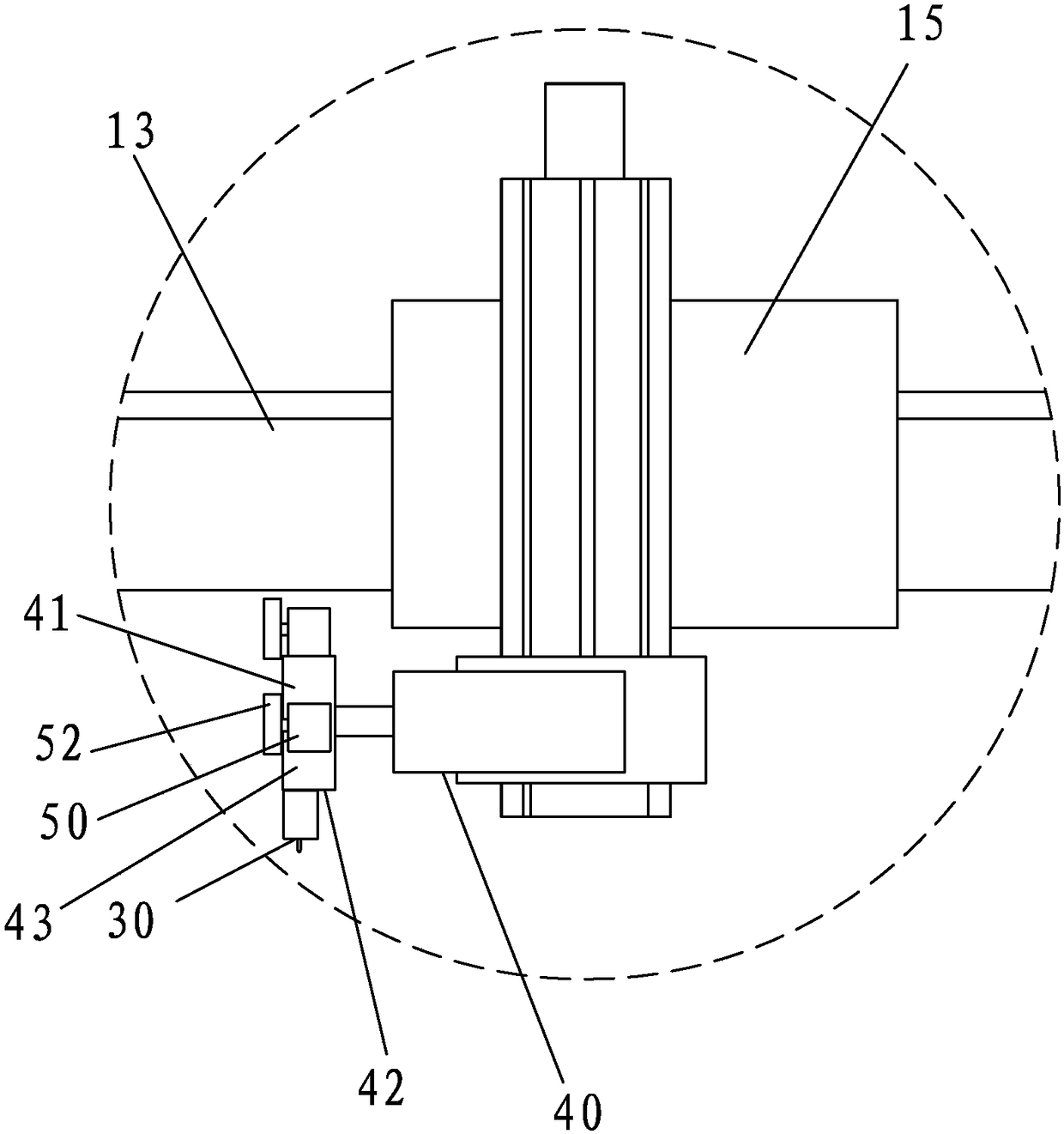

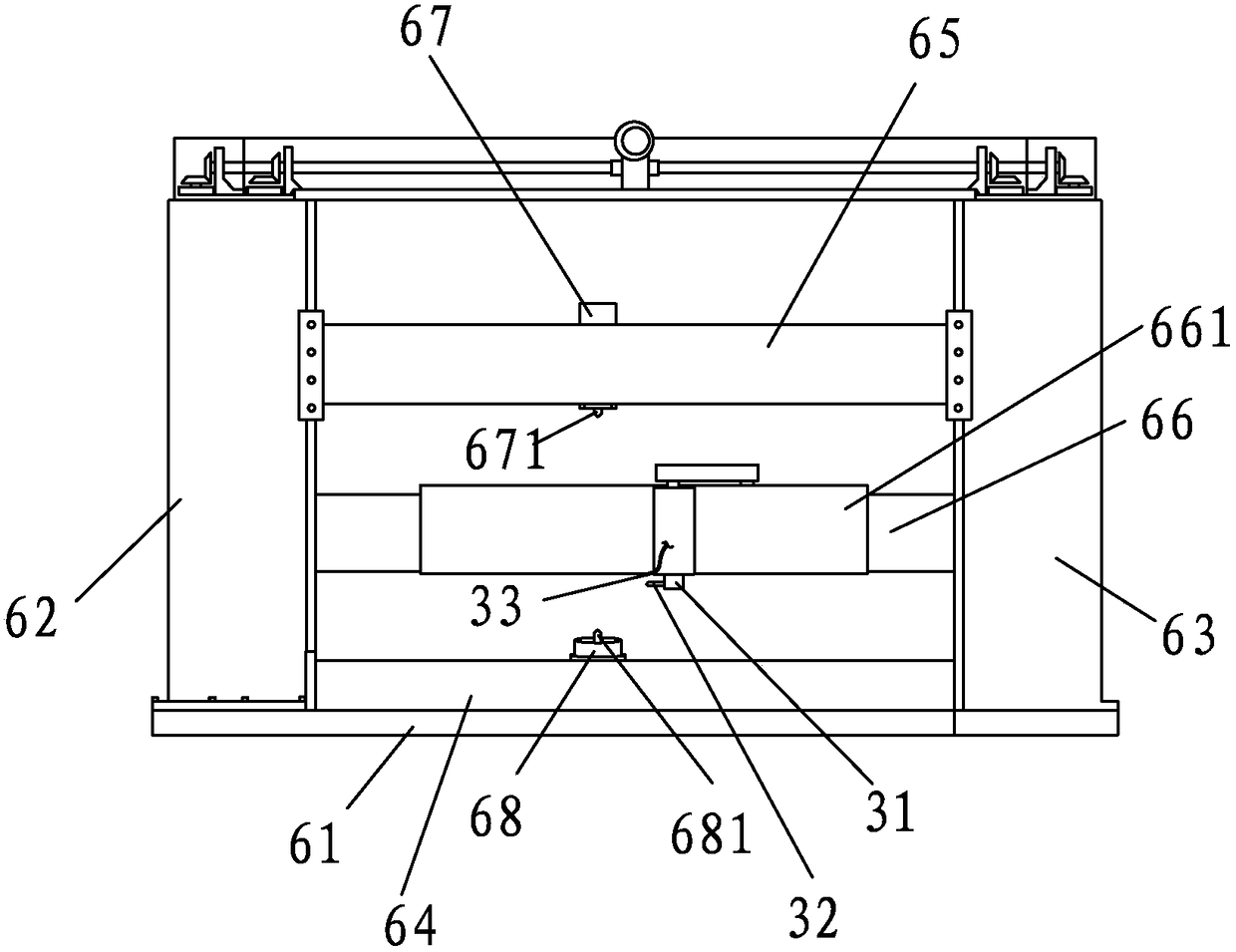

[0048] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

[0049] The grinding and polishing process of the rotary special-shaped stone railing includes the following steps:

[0050] Step A, preparing the blank body of the special-shaped stone railing. The blank body of the special-shaped stone railing is made of stone after being cut into a large surface and carved into shape; Shaped stone balustrade body in predetermined shape;

[0051] Step B: Clamp the special-shaped stone blank by the rotating clamping mechanism and drive the special-shaped stone blank to rotate. The rotation speed of the special-shaped stone blank is 300 to 1800 rpm. Carry out the first grinding and polishing of the body, the speed of the motor is 18000-24000 rpm, and the amount of carving and grinding on the surface of the special-shaped stone railing body is 1cm-2cm; The speed of the motor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com