Manufacturing device of 1500kg eight-square ingot model

A technology for making devices and models, applied in the field of 1500 kg octagonal ingot model making devices, can solve the problem of high manufacturing cost, and achieve the effects of convenient de-spinning, easy installation and disassembly, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

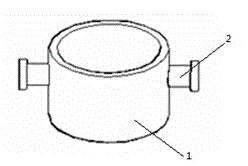

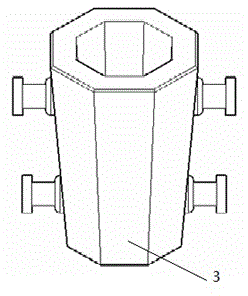

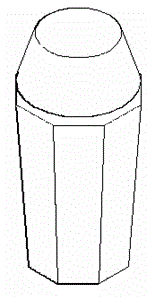

[0012] Such as figure 1 Shown, 1500 kilograms of octagonal ingot model making devices of the present invention, comprise mold 3 and cap opening 1; Described cap opening is the cap opening 1 of outer wall annular, inner cavity round platform type, and the cap opening height 24cm, and symmetrically set on the outer surface There are two hanging handles 2; the outer wall and the inner cavity surface of the mold 3 are truncated regular octagonal cones, the taper is 2.5, and the center diameter of the inner cavity is 43cm. By setting the taper of the mold at 2.5, the stripping It is convenient, and the cap opening adopts a ring cap opening with a hanging handle, which is more convenient for installation and disassembly. The ingot type can be finished at one time after being processed by a 750-ton precision forging machine, which avoids the use of the original 2-ton ingot type. Reduced costs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com