Adjusting device for horn mouth of side guide plate of hot rolling coiler and adjusting method thereof

An adjustment device and a bell mouth technology, applied in the field of metallurgical machinery, can solve the problems of unmentioned bell mouth adjustment, deformation of the body of the long-distance guide plate, reducing friction, etc. The effect of rationally oriented reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

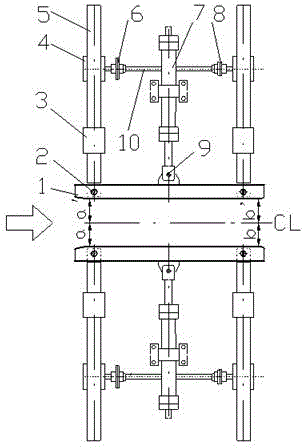

[0034] Example 1 : see figure 1 , the side guide plate has a side guide plate body 1 on the transmission side and the working side of the transmission roller table, and the distance a, a', b, b' from each side guide plate to the rolling center line CL is called the single-side opening at the corresponding position degree; the distance a+a', b+b' between the inner surfaces of the two side guide plates is called the total opening degree of the side guide plate at the corresponding position; and the opening degree a+a' on the entrance side of the side guide plate minus the opening degree b+ on the exit side b' is called the bell mouth of the side guide plate, and correspondingly, the difference a-b, a'-b' of the opening degree of one side is called the corresponding one-side bell mouth of the side guide plate. Practice has proved that it satisfies the relationship: b= b', 0<a-b≤2mm, 0<a'-b'≤2mm, that is, the outlet of the side guide plate is centered, and the opening degree of...

Embodiment 2

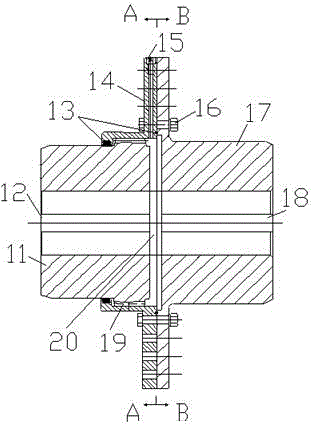

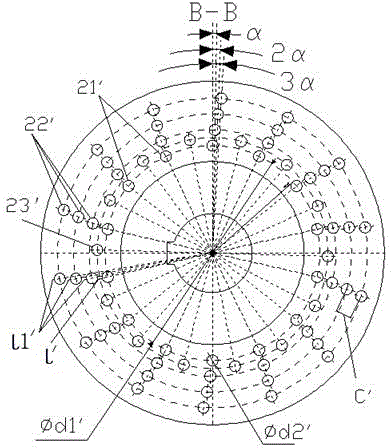

[0041] Example 2 : see Figure 1-Figure 4 Usually, the bell mouth can be measured by using the downtime such as process roll change, if the bell mouth is found to be out of the accuracy range, then loosen the bolts, and adjust the corresponding amount of the corresponding amount by rotating and fixing the coupling half 17 in the corresponding direction according to the deviation value. The indexing angle is sufficient. If it is adjusted to the bottom diameter reaming hole or the outermost top diameter expansion reaming hole, and the bell mouth of the side guide plate is still not adjusted to the required control accuracy, then the inner gear sleeve of the movable half coupling and the outer ring gear mesh Disengage, rotate the synchronous shaft 10, and drive the rack-type push rod 5 on the outlet side to move in the corresponding direction. After moving the corresponding number of teeth, close the coupling, and then perform fine adjustment according to the above method, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com